Abstract

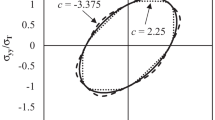

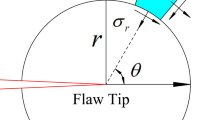

A method is described whereby values of crack tip opening displacement (COD) can be measured at any section of a pre-cracked or slotted specimen. The relationship between COD and the degree of transverse strain at the notch root of a Charpy specimen has been investigated. A specimen will show some portion in plane strain up to a COD of about one twenty-fifth of the thickness. Transverse contraction results in smaller COD values, for a particular clip gauge displacement, at the outside than at the specimen midsection.

An equation is presented relating COD to longitudinal notch root strain for Charpy specimens with root radius 0.002 in. COD and notch root strain are found to be not directly proportional. This finding is discussed in relation to the concept of a “miniature tensile specimen” at the notch root. The effect of specimen geometry on the value of COD at fracture initiation, (COD)c, has been investigated. Neither a change in specimen thickness nor a change from a fatigue pre-crack to a 0.002 in. root radius notch has been found to significantly affect (COD)c. The material used in this research was, for the most part, a low alloy pressure vessel steel, A533B.

Résumé

On décrit une méthode suivant laquelle il est possible de mesurer le COD de l'extrémité d'une fissure en une section quelconque d'une éprouvette préfissurée ou nantie d'une entaille. On a étudié la relation entre le COD et le degré de déformation transversale à la racine de l'entaille d'éprouvettes Charpy. Dans certains cas, on a constaté un état plan de déformation sur une portion appréciable d'éprouvettes dont le COD atteignait 1/25° de l'épaisseur. Une contraction transversale se traduit par des valeurs du COD plus faibles vers les bords que à mi section de l'éprouvette, dans le cas d'un déplacement donné de la clip jauge. On présente une relation entre le COD et la déformation longitudinale à la racine d'une entaille d'éprouvette Charpy avec rayon d'arrondi de 0,05 mm. Cette relation n'exprime pas une proportionnalité directe. Cette constatation est discutée en se reliant au concept d'une “éprouvette de traction miniature” qui se situerait au niveau de la racine de l'entaille. L'influence de la géométrie de l'éprouvette sur le COD critique correspondant à l'amorçage de la fissure—(COD)c—a été étudiée. On a trouvé que le (COD)c n'était pas affecté de façon significative par un changement de l'épaisseur de l'éprouvette, ou par le passage d'une préfissuration par fatigue à une entaille d'arrondi égal à 0,05 mm. La plupart des essais afférant à cette recherche ont été exécutés sur de l'acier ASTM A533 grade B-Classe 1.

Similar content being viewed by others

References

A.A., Wells, Unstable crack propagation in metals: cleavage and fast fracture, Proceedings of the Crack Propagation Symposium, The College of Aeronautics, Cranfield, England, 1 (1961) 210–230.

J. N. Robinson and A. S. Tetelman, The determination of K Ic values from measurements of the critical crack tip opening displacement at fracture initiation, presented at the Third International Conference on Fracture, Munich, Germany, April (1973).

J. N., Robinson and A. S., Tetelman, The measurement of K Ic on small specimens using critical crack tip opening displacement, presented at the Seventh National Symposium on Fracture Mechanics, University of Maryland, College Park, Maryland, August 1973. To be published in ASTM STP 559, ASTM, Philadelphia, Pennsylvania (1974).

J. N. Robinson and A. S. Tetelman, Comparison of various methods of measuring K Ic on small pre-cracked bend specimens, submitted to Engng. Fracture Mech.

F.A., McClintock, Ductile fracture instability in shear, J. Appl. Mech., 25 (1958) 582–588.

R.F. Smith and J.F. Knott, Crack opening displacement and fibrous fracture in mild steel, Conference on Practical Application of Fracture Mechanics to Pressure Vessel Technology, The Institution of Mechanical Engineers, London (1971) 65–75.

S. A. Mohamed and A. S. Tetelman, Strain and stress distribution in fully-plastic notched bars and the criterion for ductile rupture initiation, presented at the Third International Conference on Fracture, Munich, Germany, April (1973).

J.D., Landes and J.A., Begley, Test results from J integral studies, presented at the Seventh National Symposium on Fracture Mechanics, University of Maryland, College Park, Maryland, August 1973. To be published in ASTM STP 560, ASTM, Philadelphia, Pennsylvania (1974).

Standard method of test for plane-strain fracture toughness of metallic materials, E399-72, 1972 Annual Book of ASTM Standards, ASTM, Philadelphia, Pennsylvania, 31 (1972) 955–974.

H.A., Lequear and J.D., Lubahn, Root conditions in a V-notch Charpy impact specimen, Weld. Res. Suppl., 33 (1954) 585-S to 588-S.

M.A., Schroedl and C.W., Smith, Influence of three dimensional effects on the stress intensity factor for compact tension specimens, presented at the Seventh National Symposium on Fracture Mechanics, University of Maryland, College Park, Maryland, August 1973. To be published in ASTM STP 560, ASTM, Philadelphia, Pennsylvania (1974).

S.A. Mohamed, Visioplasticity analysis to stress and strain distribution during slow bend of notched steel specimens, Ph. D. in Engineering, Materials Department, University of California, Los Angeles (1972).

J.N. Robinson, The critical crack-tip opening displacement and microscopic and macroscopic fracture criteria for metals, Ph.D. in Engineering, Materials Department, University of California, Los Angeles (1973).

A.A., Wells, Application of fracture mechanics at and beyond general yielding, Br. Weld. J., 10 (1963) 563–570.

G.T., Hahn and A.R., Rosenfield, Sources of fracture toughness: the relation between K Ic and the ordinary tensile properties of metals, Applications Related Phenomena in Titanium Alloys, ASTM STP 432, ASTM, Philadelphia (1968) 5–32.

W. O., Shabbits, W. H., Pryle and E. T., Wessel, Heavy section fracture toughness properties of A533 grade B class 1 steel plate and submerged arc weldment, Westinghouse Electric Corporation, Pittsburgh, Pennsylvania, WCAP-7414, December (1969).

J.R., Rice and D.M., Tracey, On the ductile enlargement of voids in triaxial stress fields, J. Mech. Phys. Solids, 17 (1969) 201–217.

F.A., McClintock, A criterion for ductile fracture by the growth of holes, J. Appl. Mech., 35 (1968) 353–371.

P.F., Thomason, A theory for ductile fracture by internal necking of cavities, J. Inst. Metals, 96 (1968) 360–365.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Robinson, J.N., Tetelman, A.S. The relationship between crack tip opening displacement, local strain and specimen geometry. Int J Fract 11, 453–468 (1975). https://doi.org/10.1007/BF00033532

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00033532