Abstract

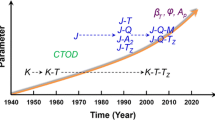

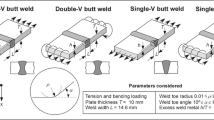

The application of the Engineering Treatment Model (ETM) to a weld metal crack in a tension loaded, transverse welded wide plate yields the applied crack tip opening displacement (CTOD) as a function of applied load or applied strain, if the stress-strain-curves of the base material and the weld metal can be expressed as piece-wise power laws. Simple analytical relationships are obtained which can serve for predicting critical loads, critical strains, or critical crack length. Large effects on the applied CTOD can occur if the weld metal's stress-strain-curve deviates from that of the base material.

Similar content being viewed by others

References

R. Denys, Provisional definitive statement on the significance of over and undermatching weld metal strength, IIW Document X-1222-91, Annual IIW Assembly, The Hague (1991).

PD 6493: 1980, Guidance on some methods for the derivation of acceptance levels for defects in fusion welded joints, British Standards Institution (1980).

I. Milne, R.A., Ainsworth, A.R. Dowling and A.T. Stewart, R6-Rev. 3, Assessment of the integrity of structures containing defects, General Electricity Generating Board (1986).

R.M. Denys, in The Fracture Mechanics of Welds, J.G. Blauel and K.-H. Schwalbe (eds.) Mechanical Engineering Publications, Bury St. Edmunds (1987).

B. Lian, R.M. Denys and L. van de Walle, An experimental assessment of the effect of weld metal yield strength overmatching in pipeline girth welds, presented at the 3rd International Conference on Welding and Performance of Pipelines, 18th–20th November 1986, London, U.K.

M. Koçak, J. Knaack and K.-H. Schwalbe, in 9th Proceedings International Conference of Offshore Mechanics and Arctic Engineering, M.M. Salama, H.C. Thee, J.G. Williams and S. Liu (eds.), The American Society of Mechanical Engineers (1990) 453–459 (GKSS 90/E/23).

D.T. Read and B.I. Petrovski, Elastic-plastic fracture at surface flaws in HSLA weldments, presented at the Fourth International Fracture Mechanics Summer School, Dubrovnik, 23th–27th June 1986.

B. Petrovski, M. Koçak and S. Sedmak, in 10th Proceedings International Conference on Offshore Mechanics and Arctic Engineering, M.M. Salama et al. (eds.), The American Society of Mechanical Engineers (1991) 101–107.

P. Dong and J.R. Gordon, in Welding 90, M. Koçak (ed.), IITT-International, Gournay-Sur-Marne, France (1990).

J.X. Zhang, Y.W. Shi and M.J. Tu, Engineering Fracture Mechanics 34 (1989) 1041–1050.

M.J. Cray, A.R. Luxmore and J.D.G. Sumpter, in ESIS/EGF 9, Defect Assessment in Components-Fundamentals and Applications, J.G. Blauel and K.-H. Schwalbe(eds.), Mechanical Engineering Publications Limited, London (1991).

K.-H. Schwalbe, International Journal of Fracture 56 (1992) 257–277.

K.-H. Schwalbe and A. Cornec, Fatigue and Fracture of Engineering Materials and Structures 14 (1991) 405–412.

J.D. Harrison, M.G. Dawes, G.L. Archer and M.S. Kamath, The COD approach and its application to welded structures, Research Report 55/1978/E, The Welding Institute (1978).

T.L. Anderson, R.H. Leggatt and S.J. Garwood, in, The Crack Tip Opening Displacement in Elastic-Plastic Fracture Mechanics, K.-H Schwalbe(ed.), Springer-Verlag, Berlin (1986).

K.-H. Schwalbe, A simple engineering treatment of centre cracked tension panels in the regime of non-linear fracture mechanics under plane stress conditions, GKSS 84/E/38, GKSS Forschungszentrum, Geesthacht (1984).

K.-H. Schwalbe, Extension of the Engineering Treatment Model (ETM) to bending configurations under plane stress, GKSS 87/E/51, GKSS Forschungszentrum (1987).

K.-H. Schwalbe, in, The Crack Tip Opening Displacement in Elastic-Plastic Fracture Mechanics, K.-H. Schwalbe (ed.), Springer Verlag, Berlin (1986).

K.-H. Schwalbe, A. Cornec and J. Heerens, in, ESIS/EGF9, Defect Assessment in Components—Fundamentals and Applications, J.G. Blauel and K.-H. Schwalbe (eds.), Mechanical Engineering Publications Limited, London (1991).

K.-H. Schwalbe and L. Grüter, in ESIS/EGF9, Defect Assessment in Components-Fundamentals and Applications (1991).

L. Grüter, Estimation of the 5th pipe experiment, Joint Fracture Mechanics Program, Program Interim Report, Interatom, Bergisch Gladbach, December 1987.

K.-H. Schwalbe and L. Grüter, Engineering Fracture Mechanics 42 (1992) 221–235.

A. Cornec and T. Seeger, Engineering Fracture Mechanics 22 (1985) 399–411.

M.T. Kirk and R.H. Dodds, Jr., Effect of weld strength mismatch on elastic-plastic fracture parameters for small tension loaded cracks, in preparation.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Schwalbe, KH. Welded joints with non-matching weld metal-crack driving force considerations on the basis of the Engineering Treatment Model (ETM). Int J Fract 62, 1–24 (1993). https://doi.org/10.1007/BF00032522

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00032522