Abstract

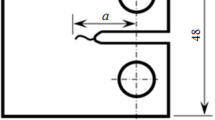

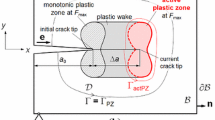

The growth rate of a stress corrosion crack in situations where linear elastic fracture mechanics (LEFM) conditions are not operative is predicted on the basis that the crack tip opening angle (CTOA) is related to the growth rate dc/dt, the functional relation between the CTOA and dc/dt being obtained by coupling theoretical results for crack growth under small-scale yielding conditions in an inert environment, with the experimentally determined power law relation between the crack tip stress intensity K and dc/dt for environmentally-assisted crack growth under LEFM conditions. Then, by assuming that the same CTOA-dc/dt relation applies to non-LEFM conditions, and by determining the CTOA under these conditions, it is in principle possible to predict the stress corrosion crack growth rate under non-LEFM conditions. A specific model: the plane strain deformation of a solid with two symmetrically situated deep cracks, and with tension of the small remaining ligament, is analyzed in detail, and the effects of the extent of plastic deformation and loading pattern (i.e., displacement or load control), on the predicted stress corrosion crack growth rate, are examined in detail. The results are compared with those obtained via application of the K versus dc/dt relation, its conversion to a J versus dc/dt correlation and then the determination of J, and also with those obtained on the assumption that a K approach is derectly applicable. The extent to which these latter approaches give conservative or non-conservative growth rate predictions when compared with the present paper's predictions, is discussed in relation to the extent of plastic deformation and loading pattern.

Résumé

On peut prédire la vitesse de croissance dc/dt d'une fissure de corrosion sous tension dans les cas où la théorie linéaire et élastique (LEFM) n'est pas applicable en se basant sur la relation que présente dc/dt avec l'angle d'ouverture de l'extrémité de la fissure (CTOA). Cette relation est obtenue en couplant des résultats théoriques de croissance de fissure sous des conditions d'écoulement plastique à petite échelle dans un environnement inerte, avec la relation parabolique expérimentale liant l'intensité de contrainte K à l'extrémité de la fissure et dc/dt obtenu sous des conditions de mécanique de rupture linéaire dans un environnement actif.

En supposant que la même relation CTOA-dc/dt est applicable aux conditions où la LEFM n'est pas valide, et en déterminant le CTOA sous ces conditions, il est en principe possible de prédire la vitesse de croissance d'une fissure en corrosion sous tension. On analyse en détail un modèle spécifique: celui de l'état plan de déformation d'un solide possédant deux fissures profondes symétriques, soumis à tension sur le ligament restant. On examine également dans le détail les effets de l'étendue de la déformation plastique et du mode de mise en charge (p.ex contrôle des déplacements ou des charges) sur les prévisions de vitesse de croissance de la fissure de corrosion sous tension.

Les résultats sont comparés avec ceux que fournit l'application de la relation K-dc/dt, de sa conversion en une correlation J-dc/dt conduisant à la détermination de J, ainsi qu'avec les résultats obtenus en supposant qu'une approche par K est directement applicable.

La mesure dans laquelle ces dernières approches produisent des prédictions de vitesse de fissuration conservatives ou non est discutée en relation avec l'étendue de la déformation plastique et le mode de mise en charge.

Similar content being viewed by others

References

E. Smith, Materials Science and Engineering 55 (1982) 97.

F.P. Ford, in Aspects of Fracture Mechanics in Pressure Vessels and Piping, Eds. S.S. Palusamy and S.G. Sampath, ASME Pressure Vessels and Piping Conference, Orlando, Florida, U.S.A. (1982) 229.

P.M. Scott and A.E. Truswell, in Aspects of Fracture Mechanics in Pressure Vessels and Piping, Eds. S.S. Palusamy and S.G. Sampath, ASME Pressure Vessels and Piping Conference, Orlando, Florida, U.S.A. (1982) 271.

R.L. Jones, F.L. Yagee, R.A. Stoehr and D. Cubicciotti, Journal of Nuclear Materials 82 (1979) 26.

E. Smith, paper accepted for publication in RES MECHANICA.

H.R. Smith, D.E. Piper and F.K. Downey, Journal of Engineering Fracture Mechanics 1 (1968) 123.

D.M. Norris, T.U. Marston, R.L. Jones and S.W. Tagart, EPRI Pressure Boundary Technology Programme, Special Report NP-1540-SR (1980) 2.

E. Smith, Materials Science and Engineering, 60 (1983) 185.

J.R. Rice and E.P. Sorensen, Journal of Mechanics and Physics of Solids 26 (1978) 163.

J.R. Rice, W.J. Drugan and T.L. Sham, in Proceedings of Twelfth National Symposium on Fracture Mechanics, ASTM STP 700 (1980) 189.

D.S. Dugdale, Journal of Mechanics and Physics 8 (1960) 100.

B.A. Bilby, A.H. Cottrell and K.H. Swinden, Proceedings of the Royal Society A 262 (1963) 304.

M.P. Wnuk, International Journal of Fracture 15 (1979) 553–581.

E. Smith, Journal of Engineering Materials and Technology 103 (1981) 148.

E. Smith, in Advances in Fracture Research, Proc. 5th Int. Conf. on Fracture, Cannes, March 1981, D. Francois (ed.), Pergamon, Oxford (1980) 1919.

B.A. Bilby, A.H. Cottrell, E. Smith and K.H. Swinden, Proceedings of the Royal Society A 279 (1964) 1.

P.C. Paris, H. Ernst and C.E. Turner, in Fracture Mechanics: Twelfth Conference, ASTM STP 700, American Society for Testing and Materials (1980) 338.

J.R. Rice, in Mechanics and Mechanisms of Crack Growth, Proceedings of Conference at Cambridge, U.K., M.J. May, Ed., British Steel Corporation Physical Metalurgy Centre Publication (1974) 14.

G.R. Egan and R.C. Cipolla, ASME Paper 78-MAT-23, American Society for Mechanical Engineers (1978).

J.R. Rice, Discussion to Reference [3].

E. Smith, unpublished work.

R. Pilkington and E. Smith, Journal of Engineering Materials and Technology 102 (1980) 347.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Smith, E. Predicting stress corrosion crack growth rates when linear elastic fracture mechanics conditions are not operative. Int J Fract 23, 213–228 (1983). https://doi.org/10.1007/BF00028824

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00028824