Abstract

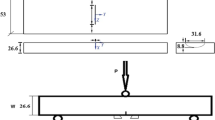

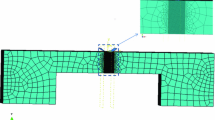

For the determination of fracture toughness especially with brittle materials, a short bar specimen with rectangular cross section and chevron notch can be used. As the crack propagates from the tip of the triangular notch, the load increases to a maximum then decreases. To obtain the relation between the fracture toughness K ic and maximum load P max, calculations of Srawley and Gross for specimens with a straight-through crack were applied to the specimens with chevron notches. For the specimens with a straight-through crack, an analytical expression was obtained. This expression was used for the calculation of the K ic−P max relation under the assumption that the change of the compliance with crack length for the specimen with a chevron notch is the same as for a specimen with a straight-through crack.

Comparative compliance calibrations with specimens of different geometries agreed very closely with the analytical results for the K ic−P max relation. For the first part of crack extension before reaching maximum load, the dimensionless quantity % MathType!MTEF!2!1!+-% feaafiart1ev1aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn% hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr% 4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq-Jc9% vqaqpepm0xbba9pwe9Q8fs0-yqaqpepae9pg0FirpepeKkFr0xfr-x% fr-xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamywamaaCa% aaleqabaGaaiOkaaaakiabg2da9iaadUeadaWgaaWcbaGaaeysaiaa% bogaaeqaaOGaamOqamaakaaabaGaam4vaaWcbeaakiaac+cacaWGqb% aaaa!3EBE!\[Y^* = K_{{\text{Ic}}} B\sqrt W /P\]where B and W are the specimen thickness and width, and P the applied load, is greater for the analytical approach than that obtained from the experimental results. This difference can be explained by applying the slice model proposed by Bluhm.

Résumé

Pour déterminer la tenacité à la rupture dans le cas particulier de matériaux fragiles, une éprouvette en forme de barreau court avec section droite rectangulaire et entaille à chevron peut être utilisée. Lorsque la fissure se propage à partir de l'extrémité de l'entaille triangulaire, la charge s'accroît jusqu'à un maximum et ensuite décroît. Pour obtenir la relation entre la tenacité à la rupture K Ic et la charge maximum P max, les calculs de Srawley et Gross pour des éprouvettes comportant une fissure droite traversante ont été appliqués aux éprouvettes comportant des entailles en chevron. Pour les éprouvettes à entailles droites traversantes, une expression analytique a été obtenue.

Cette expression a été utilisée pour le calcul de la relation de K Ic−P max sous l'hypothèse que le changement de compliance avec une longueur de fissure correspondant à l'éprouvette à entailles en chevron est la même que dans le cas d'une éprouvette comportant une fissure droite traversante.

Des calibrages comparatifs de la compliance à l'aide d'éprouvettes de géométries différentes se sont montrés en très bon accord avec les résultats analytiques correspondant à la relation K Ic−P max. Pour la première partie de l'extension de la fissure avant d'atteindre la charge maximum, la quantité sans dimension % MathType!MTEF!2!1!+-% feaafiart1ev1aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn% hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr% 4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq-Jc9% vqaqpepm0xbba9pwe9Q8fs0-yqaqpepae9pg0FirpepeKkFr0xfr-x% fr-xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamywamaaCa% aaleqabaGaaiOkaaaakiabg2da9iaadUeadaWgaaWcbaGaaeysaiaa% bogaaeqaaOGaamOqamaakaaabaGaam4vaaWcbeaakiaac+cacaWGqb% aaaa!3EBE!\[Y^* = K_{{\text{Ic}}} B\sqrt W /P\]où B et W sont respectivement l'épaisseur et la largeur de l'éprouvette, et P la charge appliquée, est supérieure dans le cas de l'approche analytique à la valeur obtenue lors des résultats expérimentaux. Cette différence peut être expliquée en appliquant le modèle de découpage en tranches proposé par Bluhm.

Similar content being viewed by others

References

L.M. Barker, Engineering Fracture Mechanics, 9 (1977) 361–369.

J. Nakajama, Journal of the American Ceramic Society, 48 (1965) 583–587.

H.G. Tattersall and G. Tappin, Journal of Materials Science, 1 (1966) 296–301.

L.M. Barker, Eleventh National Symposium on Fracture Mechanics, Blacksburg, Virginia, June 12–14, 1978. (To be published in ASTM-STP-678, 1979.)

J.E. Srawley and B. Gross, Materials Research and Standards, 7 (1967) 155–162.

J.I. Bluhm, Engineering Fracture Mechanics, 7 (1975) 593–604.

J.I. Bluhm, Fracture 1977: Advances in Research on the Strength and Fracture of Materials, Fourth Inter. Conf. on Fracture, Vol. 3, D.M.R. Taplin, ed., Pergamon Press, New York (1978) 409–417.

P.C. Paris and G.C. Sih, Fracture Toughness Testing and its Applications, ASTM-STP-381, American Society for Testing Materials, Philadelphia (1965) 30–81.

B. Gross and J.E. Srawley, “Stress Intensity Factors by Boundary Collocation for Single-Edge-Notch Specimens Subject to Splitting Forces,” NASA TN D-3295 (1966).

B. Gross, private communication.

R.T. Bubsey, D.M. Fisher, M.H. Jones and J.E. Srawley, in Experimental Techniques in Fracture Mechanics, Society for Experimental Stress Analysis Monograph 1, A.S. Kobayashi, ed., Iowa State University Press and Society for Experimental Stress Analysis, Cambridge (1973) 76–95.

W.F. BrownJr. and J.E. Srawley, Plane Strain Crack Toughness Testing of High Strength Metallic Materials, ASTM STP 410, American Society for Testing and Materials, Philadelphia (1966).

H. Hübner and W. Jillek, Journal of Materials Science, 12 (1977) 117–125.

G. Bansal and W. Duckworth, Journal of Materials Science, 13 (1978) 215–216.

D. Munz, Elastic-Plastic Fracture Mechanics, ASTM-STP-668 (1979).

Author information

Authors and Affiliations

Additional information

Work done under NASA-DOE Interagency Agreement number EC-77-A-31-1040.

Rights and permissions

About this article

Cite this article

Munz, D., Bubsey, R.T. & Srawley, J.E. Compliance and stress intensity coefficients for short bar specimens with chevron notches. Int J Fract 16, 359–374 (1980). https://doi.org/10.1007/BF00018240

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00018240