Abstract

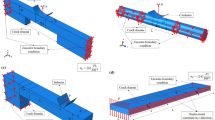

Stability of a fracture toughness testing geometry is important to determine the crack trajectory and R-curve behavior of the specimen. Few configurations provide for inherent geometric stability, especially when the specimen being tested is brittle. We propose a new geometrical construction called the single edge notched clamped bend specimen (SENCB), a modified form of three point bending, yielding stable cracking under load control. It is shown to be particularly suitable for small-scale structures which cannot be made free-standing, (e.g., thin films, coatings). The SENCB is elastically clamped at the two ends to its parent material. A notch is inserted at the bottom center and loaded in bending, to fracture. Numerical simulations are carried out through extended finite element method to derive the geometrical factor f(a/W) and \(\hbox {K}_{\mathrm{I}}\) for different beam dimensions. Experimental corroborations of the FEM results are carried out on both micro-scale and macro-scale brittle specimens. A plot of \(\hbox {K}_{\mathrm{I}}\) vs a/W, is shown to rise initially and fall off, beyond a critical a/W ratio. The difference between conventional SENB and SENCB is highlighted in terms of \(\hbox {K}_{\mathrm{I}}\) and FEM simulated stress contours across the beam cross-section. The \(\hbox {K}_{\mathrm{IC}}\)’s of bulk NiAl and Si determined experimentally are shown to match closely with literature values. Crack stability and R-curve effect is demonstrated in a PtNiAl bond coat sample and compared with predicted crack trajectories from the simulations. The stability of SENCB is shown for a critical range of a/W ratios, proving that it can be used to get controlled crack growth even in brittle samples under load control.

Similar content being viewed by others

References

Anderson TL (1994) Fracture mechanics. Taylor and Francis, New York

Ando T, Li X, Nakao S, Kasai T (2004) Effect of crystal orientation on fracture strength and fracture toughness of single crystal silicon. In: 17th IEEE international conference on. MEMS, pp 177–180

Babuska I, Melenk JM (1997) The partition of unity method. Int J Numer Methods Eng 40:727–758

Ballarini R, Mullen RL, Yin Y (1997) The fracture toughness of polysilicon microdevices: a first report. J Mater Res 12:915–922

Baratta FI, Dunlay WA (1990) Crack stability in simply supported four point and three point loaded beams of brittle materials. Mech Mater 10:149–159

Baratta FI (1988) Crack stability in two brittle nonmetallic beam systems. Exp Mech 28:310–314

Bar-On I, Baratta FI, Cho K (1996) Crack stability and its effect on fracture toughness of hot-pressed silicon nitride beam specimens. J Am Cer Soc 79:2300–2308

Bluhm JI (1977) Stability consideration in the generalized three dimensional work of fracture specimen. In: Proc fourth int conf on fract, pp 409–417

Chang KM, Darolia R, Lipsitt HA (1992) Cleavage fracture in B2 aluminides. Acta Metall Mater 40:2727–2737

Chasiotis I, Cho SW, Jonnalagadda K (2005) Fracture toughness and subcritical crack growth in polycrystalline silicon. J Appl Mech 73:714–722

Chen CP, Leipold MH (1980) Fracture toughness of silicon. Bull Am Ceram Soc 59:469–472

Chen FL, Yu TX (2004) An experimental study of pre-notched clamped beams under impact loading. Int J Solid Struct 41:6699–6724

Clausing DP (1969) Crack stability in linear elastic fracture mechanics. Int J Fract Mech 5:211–227

Jaya BN (2013) Micro-scale fracture testing of graded (Pt, Ni)Al bond coats, PhD Thesis, Materials Engineering Department, Indian Institute of Science, Bangalore

Jaya B N, Jayaram V, Biswas SK (2012) A new method for fracture toughness determination of graded (Pt, Ni)Al bond coats by microbeam bend tests. Philos Mag 92:3326–3345

John CS (1975) The ductile to brittle transition in pre-cleaved silicon single crystals. Philos Mag 32:1193–1212

Kahn H, Tayebi N, Ballarini R, Mullen RL, Heuer AH (2000) Fracture toughness of polysilicon MEMS devices. Sens Actuators 82:274–280

Laborde P, Pommier J, Renard Y, Salaun M (2005) High-order extended finite element method for cracked domains. Int J Numer Methods Eng 64:354–381

Lawn B (1993) Fracture of brittle solids. Cambridge Univeristy Press, Cambridge

Mai YW, Atkins AG (1980) Crack stability in fracture toughness testing. J Strain Anal Eng Des 15:63–74

Mai YW, Lawn BR (1986) Crack stability and toughness characteristics in brittle materials. Annu Rev Mater Sci 16:415– 439

Moes N, Dolbow J, Belytschko T (1999) A finite element method for crack growth without remeshing. Int J Numer Methods Eng 46:131–150

Murakami Y (1987) Stress intensity factors handbook. Pergamon Press, Oxford

Myers RJ, Hillberry BM (1977) Effect of notch root radius on the fracture behavior of monocrystalline silicon. Fract ICF 4(3):1001–1005

Noebe RD, Bowman RR, Nathal MV (1993) Physical and mechanical properties of the B2 compound NiAl. Int Mater Rev 38:193–232

Rubanov S, Munroe PR (2004) FIB induced damage in silicon. J Microsc 214:213–221

Sakai M, Bradt RC (1993) Fracture toughness testing of brittle materials. Int Mater Rev 38:53–78

Sharpe WN, Yuan B, Edwards RL (1997) Fracture tests of polysilicon film. MRS Symp Proc 505:51–56

Shih CF, Asaro RJ (1988) Elastic-plastic analysis of cracks on bimaterial interfaces: part I—small scale yielding. J Appl Mech 55:299–316

Sigl LS (1991) On the stability of cracks in flexure specimens. Int J Fract 51:241–254

Steinbrech R, Khehans R, Schaarwächter W (1983) Increase of crack resistance during slow crack growth in \(\text{ Al }_{2}\text{ O }_{3}\) bend specimen. J Mater Sci 18:265–270

Stolarska M, Chopp DL, Moes N, Belytschko T (2001) Modelling crack growth by level sets in the extended finite element method. Int J Numer Methods Eng 51:943–960

Sundararajan S, Bhushan B (2002) Development of AFM based techniques to measure mechanical properties of nano-scale structures. Sens Actuators A 101:338–351

Timoshenko S, Goodier JN (1951) Theory of elasticity. Tata McGraw Hill, Noida

Tsuchiya T, Sakata J, Taga Y (1997) Tensile strength and fracture toughness of surface micromachined polycrystalline silicon thin films prepared under various conditions. MRS Symp Proc 505:285–290

Acknowledgments

The authors would like to gratefully acknowledge the Defense Research Development Organisation (DRDO) for financial support. They also acknowledge the support from Hysitron Inc, USA in performing the in situ tests on PI-85. The authors would also like to thank Dr Md Z Alam and Dr D K Das, DMRL for providing bond coat samples, as well as Ms Kiruthika, IISc for providing bulk NiAl samples to carry out this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jaya, B.N., Jayaram, V. Crack stability in edge-notched clamped beam specimens: modeling and experiments. Int J Fract 188, 213–228 (2014). https://doi.org/10.1007/s10704-014-9956-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-014-9956-2