Abstract

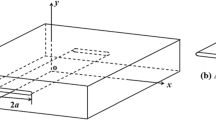

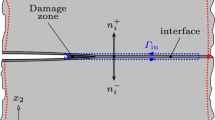

Asymmetrically cracked specimens fail with considerably less ductility than symmetrically cracked ones, due to the crack progressing along a shear band into pre-damaged material. A formulation for the accumulation of damage ahead of an asymmetric crack is presented, based on strain increments following a power law relation. These results are integrated both numerically and approximately.

The crack growth per unit displacement increases approximately as the logarithm of the total crack advance per inclusion spacing р, and varies inversely as the critical fracture strain γc. This provides a basis for predicting large-scale, fully plastic fracture from asymmetric weld defects, using small-scale laboratory specimens.

Résumé

Les éprouvettes fissurées de manière asymétrique se rompent avec beaucoup moins de ductilité que celles qui sont fissurées de manières symétrique, en raison du fait que la fissure se développe suivant une bande de cisaillement dans un matériau préendommagé. On Présente une formulation de l'accumulation du dommage en avant d'une fissure asymétrique, en se basant sur des gradients de déformations répartis selon une loi quadratique. L'interprétation des résultats est effectuée par voie numérique et par approximation.

On constate que le croissance d'une fissure par unité de déplacement est sensiblement proportionnelle au logarithme de l'avancement total de la fissure rapporté à l'espacement entre deux inclusions р, et en raison inverse de la déformation critique à la rupture γc. Ceci fournt une base pour prédire une rupture à plus grande échelle et en conditions tout à fait plastiques, qui résulteront de défauts de soudage asymétriques, et ce en utilisant des éprouvettes réduites de laboratoire.

Similar content being viewed by others

References

C.D. Beachem and D.A. Meyn, in Electron Fractography, ASTM STP 436, American Society for Testing and Materials, Philadelphia (1968) 58–88.

J.A. Fellows, ed., in Metals Handbook: Fractography and Atlas of Fractographs, 8th edn., American Society for Metals, Metals Park, Ohio (1974) 79–92.

F.A. McClintock, Journal of Applied Mechanics 25 (1958) 581–588.

C.F. Shih, in Fracture Analysis, ASTM STP 560, American Society for Testing and Materials, Philadelphia (1974) 187–210.

H.W. Swift, Journal of Mechanics and Physics of Solids 1 (1952) 1–18.

J.W. Hutchinson, Journal of Mechanics and Physics of Solids 16 (1968) 13–31.

J.R. Rice and G.F. Rosengren, Journal of Mechanics and Physics of Solids 16 (1968) 1–12.

F.A. McClintock, S.M. Kaplan and C.A. Berg, International Journal of Fracture Mechanics 2 (1966) 614–627.

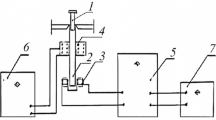

A.H. Slocum and F.A. McClintock, “User's and Programmers' Manuals for ASYMCR to Predict Fully Plastic Mode II Asymmetric Crack Growth”, Research Memo 263, Fatigue and Plasticity Laboratory, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA (1984).

J.R. Rice, W.J. Drugan and T.L. Sham, in Fracture Mechanics: 12th Conference, ASTM STP 700, American Society for Testing and Materials, Philadelphia (1980) 189–221.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mcclintock, F.A., Slocum, A.H. Predicting fully plastic mode II crack growth from an asymmetric defect. Int J Fract 27, 49–62 (1985). https://doi.org/10.1007/BF00017212

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00017212