Abstract

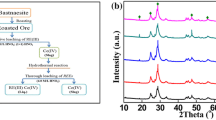

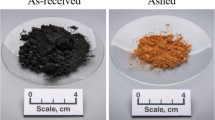

This study investigates the chemical associations of the selected rare-earth elements (Sc, Y, Ce, La, and Nd) with major element phases in the postprocessed bauxite residues and compares them with the untreated bauxite residue. The treatment of bauxite residue considers our previous published process which involved the neutralization with CO2, followed by leaching with H2SO4. Neutralized bauxite residue resulted with larger aggregates than the untreated bauxite residue after making contact with CO2 as the consequence of additional CaCO3 formation. Neutralization with CO2, however, has a negligible effect on the distribution of the rare-earth elements (REEs) with respect to the untreated bauxite residue, but a large amount of rare earths remained unreacted after acid leaching. Electron probe microanalysis (EPMA) confirmed the chemical associations of Sc(III) and Ce(IV) with Fe(III)- and Al(III)-containing minerals in the postprocessed bauxite residues, i.e., bauxite residues subjected to CO2-neutralization and neutralization–acid leaching processes. The occurrence of Nd(III) is positively correlated to that of La(III) in the untreated bauxite residue, but both of them may be associated with the same mineralogical phase as Ce(IV) after processing. Y(III) may remain associated with the Al/Si-minerals, cancrinite and chamosite. Ergo, the extractability of Sc, Y, Ce, La, and Nd from neutralized bauxite residue is more difficult in H2SO4 media due to the presence of coarser particles compared to those of the untreated bauxite residue, but also due to the formation of a solid product layer (i.e., CaSO4) that is presumably adsorbed on the surface of Fe(III)-rich phases (hematite and goethite) and Al(III)-containing minerals (diaspore, gibbsite, boehmite, and chamosite).

[reprinted from (Rivera et al. [22])] with permission of Elsevier; license number: 4212401452947)

[adapted from (Rivera et al. [22])]

Similar content being viewed by others

References

Gan BK, Taylor Z, Xu B et al (2013) Quantitative phase analysis of bauxites and their dissolution products. Int J Miner Process 123:64–72. https://doi.org/10.1016/j.minpro.2013.05.005

Bárdossy G (1997) Berthier, les Baux et l’histoire de la bauxite. Comptes Rendus l’Academie Sci 324:1031–1040. https://doi.org/10.1016/S1251-8050(97)83989-4

Borra CR, Blanpain B, Pontikes Y et al (2016) Recovery of rare earths and other valuable metals from bauxite residue (red mud): a review. J Sustain Metall 2:365–386. https://doi.org/10.1007/s40831-016-0068-2

Mordberg LE (1993) Patterns of distribution and behaviour of trace elements in bauxites. Chem Geol 107:241–244. https://doi.org/10.1016/0009-2541(93)90183-J

Deady E, Mouchos E, Goodenough K, et al (2014) Rare earth elements in karst-bauxites: a novel untapped European resource? In: ERES2014: 1st European Rare Earth Resources Conference (Milos, Greece, 4–7 September 2014). pp 364–375

Li Z, Din J, Xu J et al (2013) Discovery of the REE minerals in the Wulong-Nanchuan bauxite deposits, Chongqing, China: insights on conditions of formation and processes. J Geochem Explor 133:88–102. https://doi.org/10.1016/j.gexplo.2013.06.016

Retallack GJ (2010) Lateritization and bauxitization events. Econ Geol 105:655–667. https://doi.org/10.2113/gsecongeo.105.3.655

Kaya S, Topkaya YA (2015) Extraction behavior of scandium from a refractory nickel laterite ore during the pressure acid leaching process. In: Rare earths industry: technological, economic, and environmental implications. pp 177–188

Birgul O (1981) Sacndium-iron correlation in clay minerals. Earth Planeta Sci Lett 55:450–452

Binnemans K, Jones PT, Blanpain B et al (2015) Towards zero-waste valorisation of rare-earth-containing industrial process residues: a critical review. J Clean Prod 99:17–38. https://doi.org/10.1016/j.jclepro.2015.02.089

Wagh AS, Pinnock WR (1987) Occurrence of scandium and rare earth elements in Jamaican bauxite waste. Econ Geol 82:757–761. https://doi.org/10.2113/gsecongeo.82.3.757

Borra CR, Pontikes Y, Binnemans K, Van Gerven T (2015) Leaching of rare earths from bauxite residue (red mud). Miner Eng 76:20–27. https://doi.org/10.1016/j.mineng.2015.01.005

Rudnick R, Gao S (2003) Composition of the continental crust. Pergamon, Oxford

Patterson SH, Kurtz HF, Olson JC, Neeley CL (1986) World Bauxite Resources. In: U.S. Geological Survey professional paper. Washington

Vind J, Vassiliadou V, Panias D (2017) Distribution of trace elements through the bayer process and its by-products. In: 35th International ICSOBA Conference, Hamburg, Germany, Oct 2–5, 2017. pp 255–267

Laintz KE, Wai CM, Yonker CR, Smith RD (1992) Extraction of metal ions from liquid and solid materials by supercricitical carbon dioxide. Anal Chem 64:2875–2878

Smith P (2015) Reactions of lime under high temperature Bayer digestion conditions. Hydrometallurgy. https://doi.org/10.1016/j.hydromet.2016.02.011

Bánvölgyi GG (2016) Scale Formation in Alumina Refineries. In: Travaux 45, Proceedings of 34th International ICSOBA Conference. Quebec, pp 1–14

Suss A, Kuznetsova N V, Kozyrev A, Panov A (2017) Specific Features of Scandium Behavior during Sodium Bicarbonate Digestion of Red Mud. In: 35th International ICSOBA Conference, Hamburg, Germany, October 2–5, 2017. pp 491–504

Vind J, Mal A, Bonomi C et al (2018) Modes of occurrences of scandium in Greek bauxite and bauxite residue. Miner Eng 123:35–48. https://doi.org/10.1016/j.mineng.2018.04.025

Evans K (2016) The history, challenges, and new developments in the management and use of bauxite residue. J Sustain Metal 2:316–331. https://doi.org/10.1007/s40831-016-0060-x

Rivera RM, Ounoughene G, Borra CR et al (2017) Neutralisation of bauxite residue by carbon dioxide prior to acidic leaching for metal recovery. Miner Eng 112:92–102. https://doi.org/10.1016/j.mineng.2017.07.011

Ochsenkuhn-Petropulu M, Lyberopulu T, Parissakis G (1994) Direct determination of lanthanides, yttrium and scandium in bauxites and red mud from alumina production. Anal Chim Acta 296:305–313. https://doi.org/10.1016/0003-2670(94)80250-5

Vind J, Malfliet A, Blanpain B et al (2018) Rare earth element phases in bauxite residue. Minerals 8:1–32. https://doi.org/10.20944/preprints201801.0288.v1

Gamaletsos PN, Godelitsas A, Filippidis A, Pontikes Y (2018) The rare earth elements potential of greek bauxite active mines in the light of a sustainable REE demand. J Sustain Metal. https://doi.org/10.1007/s40831-018-0192-2

Mongelli G (1997) Ce-anomalies in the textural components of Upper Cretaceous karst bauxites from the Apulian carbonate platform (southern Italy). Chem Geol 140:69–79. https://doi.org/10.1016/S0009-2541(97)00042-9

Maksimovic Z, Panto G (1991) Contribution to the geochemistry of the rare earth elements in the karst-bauxite deposits of Yugoslavia and Greece. Geoderma 51:93–109. https://doi.org/10.1016/0016-7061(91)90067-4

Zhang N, Li H-X, Cheng H-J, Liu X-M (2017) Electron probe microanalysis for revealing occurrence mode of scandium in Bayer red mud. Rare Met 36:295–303. https://doi.org/10.1007/s12598-017-0893-x

Das HA, Zonderhuis J (1971) Scandium in rocks, minerals and sediments and its relations to iron and aluminium. Contrib Miner Petrol 32:231–244

Liu Z, Zong Y, Li H, Zhao Z (2018) Characterization of scandium and gallium in red mud with Time of Flight- Secondary Ion Mass Spectrometry (ToF-SIMS) and Electron Probe Micro- Analysis (EPMA). Miner Eng 119:263–273

Shannon RD (1976) Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr Sect A 32:751–767. https://doi.org/10.1107/S0567739476001551

Urbain G, Sarkar PB (1927) Sur les analogies du scandium avec les éléments des terres rares et avec les éléments trivalents de la famille du fer. Compt Rend 185:593–596

Rivera RM, Ulenaers B, Ounoughene G et al (2018) Extraction of rare earths from bauxite residue (red mud) by dry digestion followed by water leaching. Miner Eng 119:82–92. https://doi.org/10.1016/j.mineng.2018.01.023

Sajó IE (2008) X-ray diffraction quantitative phase analysis of bayer process solids. International ICSOBA Conference. Bhubaneswar, India, pp 71–76

Wang S, Ang HM, Tadé MO (2008) Novel applications of red mud as coagulant, adsorbent and catalyst for environmentally benign processes. Chemosphere 72:1621–1635. https://doi.org/10.1016/j.chemosphere.2008.05.013

Rao BH, Reddy NG (2017) Zeta potential and particle size characteristics of red mud waste. Geoenvironmental practices and sustainability. Springer Nature Singapore Pte Ltd., Odisha, pp 69–89

Santini TC (2015) Application of the Rietveld refinement method for quantification of mineral concentrations in bauxite residues (alumina refining tailings). Int J Miner Process 139:1–10. https://doi.org/10.1016/j.minpro.2015.04.004

Gräfe M, Power G, Klauber C (2011) Bauxite residue issues: iII. Alkalinity and associated chemistry. Hydrometallurgy 108:60–79. https://doi.org/10.1016/j.hydromet.2011.02.004

Rai S, Wasewar K, Agnihotri A (2017) Treatment of alumina refinery waste (red mud) through neutralization techniques: a review. Waste Manag Res 35:563–580. https://doi.org/10.1177/0734242X17696147

Palmer SJ, Frost RL (2009) Characterisation of bauxite and seawater neutralised bauxite residue using XRD and vibrational spectroscopic techniques. J Mater Sci 44:55–63. https://doi.org/10.1007/s10853-008-3123-y

Ghorbani Y, Becker M, Petersen J et al (2013) Investigation of the effect of mineralogy as rate-limiting factors in large particle leaching. Miner Eng 52:38–51. https://doi.org/10.1016/j.mineng.2013.03.006

Ghorbani Y, Becker M, Mainza A et al (2011) Large particle effects in chemical/biochemical heap leach processes—a review. Miner Eng 24:1172–1184. https://doi.org/10.1016/j.mineng.2011.04.002

Blott SJ, Pye K (2012) Particle size scales and classification of sediment types based on particle size distributions: review and recommended procedures. Sedimentology 59:2071–2096. https://doi.org/10.1111/j.1365-3091.2012.01335.x

Ochsenkühn-Petropulu M, Lyberopulu T, Ochsenkühn KM, Parissakis G (1996) Recovery of lanthanides and yttrium from red mud by selective leaching. Anal Chim Acta 319:249–254. https://doi.org/10.1016/0003-2670(95)00486-6

Mohd F, Abdul H, Stoll S (2018) Hematite (α-Fe2O3)—a potential Ce4+ carrier in redmud RalphM. Sci Total Environ 622–623:849–860. https://doi.org/10.1016/j.scitotenv.2017.12.043

Reid S, Tam J, Yang M, Azimi G (2017) Technospheric mining of rare earth elements from bauxite residue (Red Mud): process optimization, kinetic investigation, and microwave pretreatment. Sci Rep 7:15252. https://doi.org/10.1038/s41598-017-15457-8

Lei W, Linsalata P, Franca EP (1986) Distribution and mobilization of cerium, lanthanum and neodymium in The Morro do Ferro Basin, Brazil. Chem Geol 55:313–322

Borra CR, Blanpain B, Pontikes Y et al (2016) Smelting of bauxite residue (red mud) in view of iron and selective rare earths recovery. J Sustain Metall 2:28–37. https://doi.org/10.1007/s40831-015-0026-4

Kul M, Topkaya Y, Karakaya I (2008) Rare earth double sulfates from pre-concentrated bastnasite. Hydrometallurgy 93:129–135. https://doi.org/10.1016/j.hydromet.2007.11.008

Abreu RD, Morais CA (2010) Purification of rare earth elements from monazite sulphuric acid leach liquor and the production of high-purity ceric oxide. Miner Eng 23:536–540. https://doi.org/10.1016/j.mineng.2010.03.010

Caccia VG, Millero FJ (2007) Distribution of yttrium and rare earths in Florida Bay sediments. Mar Chem 104:171–185. https://doi.org/10.1016/j.marchem.2006.11.001

Graf JL (1978) Rare earth elements, iron formations and sea water. Geochim Cosmochim Acta 42:1845–1850. https://doi.org/10.1016/0016-7037(78)90239-9

Johan V, Johan Z (2005) Accessory minerals of the Cínovec (Zinnwald) granite cupola, Czech Republic: indicators of petrogenetic evolution. Miner Petrol 83:113–150. https://doi.org/10.1007/BF01159735

Liu W, Yang J, Xiao B (2009) Review on treatment and utilization of bauxite residues in China. Int J Miner Process 93:220–231. https://doi.org/10.1016/j.minpro.2009.08.005

Myerson A (2002) Handbook of Industrial Crystallization, second edition. Boston

Borra CR, Mermans J, Blanpain B et al (2016) Selective recovery of rare earths from bauxite residue by combination of sulfation, roasting and leaching. Miner Eng 92:151–159. https://doi.org/10.1016/j.mineng.2016.03.002

Pontikes Y, Angelopoulos GN (2013) Bauxite residue in cement and cementitious applications: current status and a possible way forward. Resour Conserv Recycl 73:53–63. https://doi.org/10.1016/j.resconrec.2013.01.005

Acknowledgements

The above research leading to these results has received funding from the European Community’s Horizon 2020 Programme (H2020/2014–2019) under Grant Agreement No. 636876 (MSCA- ETN REDMUD). This publication reflects only the authors’ view, exempting the Community from any liability. Project website: http://www.etn.redmud.org.

Author information

Authors and Affiliations

Corresponding author

Additional information

The contributing editor for this article was Markus Reuter.

Rights and permissions

About this article

Cite this article

Rivera, R.M., Ounoughene, G., Malfliet, A. et al. A Study of the Occurrence of Selected Rare-Earth Elements in Neutralized–Leached Bauxite Residue and Comparison with Untreated Bauxite Residue. J. Sustain. Metall. 5, 57–68 (2019). https://doi.org/10.1007/s40831-018-0206-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-018-0206-0