Abstract

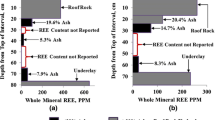

This work is a first-order study to assess the suitability of an organic acid lixiviant to extract rare earth elements (REE) from coal preparation fines refuse sourced from a Pennsylvania mine with a total REE of ~ 300 ppm. The extraction of REE using an organic acid, in this case 0.1 M citric acid and 0.5 M trisodium citrate solution, is compared against 0.5 M (NH4)2SO4, 1 M HCl, 1.2 M H2SO4, and 0.5 M ethylenediaminetetraacetic acid (EDTA). Ashing the coal waste material prior to leaching tests with the citrate solution nominally improved REE extraction. Buffered citrate solution recovered 7% of the total REE in the as-received Isabella Fines as compared to 11% in ashed samples, whereas (NH4)2SO4 extracted 5–6%, respectively. EDTA recovered up to 33% of the total REE, most likely due to the higher coordination chelate bond. Mineral acids, however, outperformed the organic acids on ashed material (16–52% REE recovery), suggesting that organic acids may not be a suitable competitive option for REE extraction from these types of feedstocks.

Similar content being viewed by others

References

Pulidindi K, Pandey H (2017) Rare earth metals market size by metal (cerium, dysprosium, erbium, europium, gadolinium, holmium, lanthanum, lutetium, neodymium, praseodymium, promethium, samarium, scandium, terbium, thulium, ytterbium, yttrium), by applications (magnets, colorants, Al. https://www.gminsights.com/industry-analysis/rare-earth-metals-market?utm_source=globenewswire.com&utm_medium=referral&utm_campaign=Paid_Globnewswire. Accessed 2 Apr 2019

Ganguli R, Cook DR (2018) Rare earths: a review of the landscape. MRS Energy Sustain 5. https://doi.org/10.1557/mre.2018.7

Bauer D, Diamond D, Li J, Sandalow D, Telleen P, Wanner B (2010) U.S. Department of Energy Critical Materials Strategy. United States: N. p. Web. https://doi.org/10.2172/1000846

Moldoveanu GA, Papangelakis VG (2012) Recovery of rare earth elements adsorbed on clay minerals: I. Desorption mechanism. Hydrometallurgy 117–118:71–78. https://doi.org/10.1016/j.hydromet.2012.02.007

U.S. Geological Survey (2017) Mineral commodity summaries 2017: U.S. Geological Survey, pp 202. https://doi.org/10.3133/70180197

Appalachian Region Independent Power Producers Association (2018) Coal refuse [White Paper]. https://arippa.org/wp-content/uploads/2018/12/ARIPPA-Coal-Refuse-Whitepaper-with-Photos-10_05_15.pdf

Lin R, Stuckman M, Howard BH, Bank TL, Roth EA, Macala MK, Lopano C, Soong Y, Granite EJ (2018) Application of sequential extraction and hydrothermal treatment for characterization and enrichment of rare earth elements from coal fly ash. Fuel 232:124–133. https://doi.org/10.1016/j.fuel.2018.05.141

Taggart RK, Hower JC, Hsu-Kim H (2018) Effects of roasting additives and leaching parameters on the extraction of rare earth elements from coal fly ash. Int J Coal Geol 196:106–114. https://doi.org/10.1016/j.coal.2018.06.021

Rozelle PL, Khadilkar AB, Pulati N, Soundarrajan N, Klima MS, Mosser MM, Miller CE, Pisupati SV (2016) A study on removal of rare earth elements from U.S. coal byproducts by ion exchange. Metall Mater Trans E 3:6–17. https://doi.org/10.1007/s40553-015-0064-7

U.S. Department of Energy (2017) Report on rare earth elements from coal and coal byproducts. U.S. Department of Energy. https://www.energy.gov/sites/prod/files/2018/01/f47/EXEC-2014-000442%20-%20for%20Conrad%20Regis%202.2.17.pdf

Huang Q, Noble A, Herbst J, Honaker R (2018) Liberation and release of rare earth minerals from Middle Kittanning, Fire Clay, and West Kentucky No. 13 coal sources. Powder Technol 332:242–252. https://doi.org/10.1016/j.powtec.2018.03.063

Peelman S, Sun ZHI, Sietsma J, Yang Y (2016) Leaching of rare earth elements: review of past and present technologies. Rare Earths Ind:319–334. https://doi.org/10.1016/B978-0-12-802328-0.00021-8

Krishnamurthy N, Gupta CK (2016) Extractive metallurgy of rare earths. Taylor and Francis Group, CRC Press, Boca Raton, Fl

Moldoveanu GA, Papangelakis VG (2013) Recovery of rare earth elements adsorbed on clay minerals: II. Leaching with ammonium sulfate. Hydrometallurgy 131–132:158–166. https://doi.org/10.1016/j.hydromet.2012.10.011

Goyne KW, Brantley SL, Chorover J (2010) Rare earth element release from phosphate minerals in the presence of organic acids. Chem Geol 278:1–14. https://doi.org/10.1016/j.chemgeo.2010.03.011

Montross SN, Yang J, Britton J, McKoy M, Verba C (2020) Leaching of rare earth elements from central Appalachian coal seam underclays. Minerals 10:577. https://doi.org/10.3390/MIN10060577

Eberl DD (2003) User’s Guide to RockJock - a program for determining quantitative mineralogy from powder x-ray diffraction data. USGS Open-File Report 2003-78, U.S. Geological Survey. https://pubs.usgs.gov/of/2003/of03-078/pdf/RockMan7.pdf

Honaker R, Yang X, Chandra A, Zhang W, Werner J (2018) Hydrometallurgical extraction of rare earth elements from coal. In: Davis B et al (eds) Extraction 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-95022-8_193

Poppe LJ, Paskevich VF, Hathway JC, Blackwood DS (2001) A laboratory manual for X-ray powder diffraction, USGS Open-File Report, U.S. Geological Survey. pp 2001–2041. https://pubs.usgs.gov/of/2001/of01-041/

Wyrzykowski D, Chmurzyński L (2010) Thermodynamics of citrate complexation with Mn2+, Co2+, Ni2+ and Zn2+ ions. J Therm Anal Calorim 102:61–64. https://doi.org/10.1007/s10973-009-0523-4

Papagianni M (2007) Advances in citric acid fermentation by Aspergillus niger: biochemical aspects, membrane transport and modeling. Biotechnol Adv 25:244–263

Navrotsky A, Mazeina L, Majzlan J (2008) Size-driven structural and thermodynamic complexity in iron oxides. Science (80-. ) 319:1635–1638

Acknowledgements

This technical effort was performed in support of the National Energy Technology Laboratory’s ongoing research for the Department of Energy Rare Earth Elements Program. We thank Mary Anne Alvin (DOE Rare Earths Technology Manager), Thomas Tarka (REE FWP Technical Portfolio Lead), and Mark McKoy for their support. We would also like to thank Stanley Seers for providing the Isabella fines material. This research was supported in part by a postdoctoral appointment to the National Energy Technology Laboratory Research Participation Program, sponsored by the US Department of Energy and administered by the Oak Ridge Institute for Science and Education.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Disclaimer

This report was prepared as an account of work sponsored by an agency of the US Government. Neither the US Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the US Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the US Government or any agency thereof.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Coal waste evaluated for REE extractability using organic acids.

• REE extraction with the citrate is independent of pH between pH 2 and 5.

• Citrate anion is competitive with (NH4)2SO4 in extraction of REE from these feedstocks.

• Ashing the coal fines feedstock results in a 5-fold increase in total REE mass recovered.

• EDTA can extract nearly 3 times greater amounts of REE on ashed feedstocks than citrate solutions but also higher levels of gangue elements.

• Inorganic mineral acids (HCl, H2SO4) are more effective at REE extraction from ashed material versus organic acids.

Rights and permissions

About this article

Cite this article

Yang, J., Montross, S. & Verba, C. Assessing the Extractability of Rare Earth Elements from Coal Preparation Fines Refuse Using an Organic Acid Lixiviant. Mining, Metallurgy & Exploration 38, 1701–1709 (2021). https://doi.org/10.1007/s42461-021-00439-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-021-00439-2