Abstract

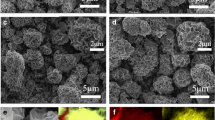

We report a simple method of preparing a high performance, Sn-based anode material for lithium ion batteries (LIBs). Adding H2O2 to an aqueous solution containing Sn2+ and aniline results in simultaneous polymerization of aniline and oxidation of Sn2+ to SnO2, leading to a homogeneous composite of polyaniline and SnO2. Hydrogen thermal reduction of the above composite yields N-doped carbon with hierarchical porosity and homogeneously distributed, ultrafine Sn particles. The nanocomposite exhibits excellent performance as an anode material for lithium ion batteries, showing a high reversible specific capacity of 788 mAh·g−1 at a current density of 100 mA·g−1 after 300 cycles and very good stability up to 5,000 mA·g−1. The simple preparation method combined with the good electrochemical performance is highly promising to promote the application of Sn based anode materials.

Similar content being viewed by others

References

Crabtree, G. Perspective: The energy-storage revolution. Nature 2015, 526, S92.

Tarascon, J. M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367.

Goodenough, J. B.; Kim, Y. Challenges for rechargeable Li batteries. Chem. Mater. 2010, 22, 587–603.

Ghadbeigi, L.; Harada, J. K.; Lettiere, B. R.; Sparks, T. D. Performance and resource considerations of Li-ion battery electrode materials. Energy Environ. Sci. 2015, 8, 1640–1650.

Park, C. M.; Kim, J. H.; Kim, H.; Sohn, H. J. Li-alloy based anode materials for Li secondary batteries. Chem. Soc. Rev. 2010, 39, 3115–3141.

Dahn, J. R.; Zheng, T.; Liu, Y. H.; Xue, J. S. Mechanisms for lithium insertion in carbonaceous materials. Science 1995, 270, 590–593.

Kaskhedikar, N. A.; Maier, J. Lithium storage in carbon nanostructures. Adv. Mater. 2009, 21, 2664–2680.

Liu, J.; Song, K. P.; Zhu, C. B.; Chen, C. C.; van Aken, P. A.; Maier, J.; Yu, Y. Ge/C nanowires as high-capacity and long-life anode materials for Li-ion batteries. ACS Nano 2014, 8, 7051–7059.

Kim, H.; Seo, M.; Park, M. H.; Cho, J. A critical size of silicon nano-anodes for lithium rechargeable batteries. Angew. Chem., Int. Ed. 2010, 49, 2146–2149.

Li, S.; Niu, J. J.; Zhao, Y. C.; So, K. P.; Wang, C.; Wang, C. A.; Li, J. High-rate aluminium yolk-shell nanoparticle anode for Li-ion battery with long cycle life and ultrahigh capacity. Nat. Commun. 2015, 6, 7872.

Mangolini, L.; Kortshagen, U. Plasma-assisted synthesis of silicon nanocrystal inks. Adv. Mater. 2007, 19, 2513–2519.

Oumellal, Y.; Rougier, A.; Nazri, G. A.; Tarascon, J. M.; Aymard, L. Metal hydrides for lithium-ion batteries. Nat. Mater. 2008, 7, 916–921.

Pumera, M. Graphene-based nanomaterials for energy storage. Energy Environ. Sci. 2011, 4, 668–674.

Winter, M.; Besenhard, J. O. Electrochemical lithiation of tin and tin-based intermetallics and composites. Electrochim. Acta 1999, 45, 31–50.

Zhang, Y. J.; Jiang, L.; Wang, C. R. Preparation of a porous Sn@C nanocomposite as a high-performance anode material for lithium-ion batteries. Nanoscale 2015, 7, 11940–11944.

Wang, J. W.; Fan, F. F.; Liu, Y.; Jungjohann, K. L.; Lee, S. W.; Mao, S. X.; Liu, X. H.; Zhu, T. Structural evolution and pulverization of tin nanoparticles during lithiation-delithiation cycling. J. Electrochem. Soc. 2014, 161, F3019–F3024.

Liu, Y. C.; Zhang, N.; Jiao, L. F.; Chen, J. Tin nanodots encapsulated in porous nitrogen-doped carbon nanofibers as a free-standing anode for advanced sodium-ion batteries. Adv. Mater. 2015, 27, 6702–6707.

Luo, B.; Qiu, T. F.; Ye, D. L.; Wang, L. Z.; Zhi, L. J. Tin nanoparticles encapsulated in graphene backboned carbonaceous foams as high-performance anodes for lithium-ion and sodium-ion storage. Nano Energy 2016, 22, 232–240.

Luo, B.; Qiu, T. F.; Hao, L.; Wang, B.; Jin, M. H.; Li, X. L.; Zhi, L. J. Graphene-templated formation of 3D tin-based foams for lithium ion storage applications with a long lifespan. J. Mater. Chem. A 2016, 4, 362–367.

Cho, J. S.; Kang, Y. C. Nanofibers comprising yolk-shell Sn@void@SnO/SnO2 and hollow SnO/SnO2 and SnO2 nanospheres via the kirkendall diffusion effect and their electrochemical properties. Small 2015, 11, 4673–4681.

Li, W.; Yang, R.; Zheng, J.; Li, X. G. Tandem plasma reactions for Sn/C composites with tunable structure and high reversible lithium storage capacity. Nano Energy 2013, 2, 1314–1321.

Zhu, Z. Q.; Wang, S. W.; Du, J.; Jin, Q.; Zhang, T. R.; Cheng, F. Y.; Chen, J. Ultrasmall Sn nanoparticles embedded in nitrogen-doped porous carbon as high-performance anode for lithium-ion batteries. Nano Lett. 2014, 14, 153–157.

Li, L. M.; Liu, E. H.; Li, J.; Yang, Y. J.; Shen, H. J.; Huang, Z. Z.; Xiang, X. X.; Li, W. A doped activated carbon prepared from polyaniline for high performance supercapacitors. J. Power Sources 2010, 195, 1516–1521.

Xu, Y. H.; Liu, Q.; Zhu, Y. J.; Liu, Y. H.; Langrock, A.; Zachariah, M. R.; Wang, C. S. Uniform nano-Sn/C composite anodes for lithium ion batteries. Nano Lett. 2013, 13, 470–474.

Hu, P. F.; Wang, H.; Yang, Y.; Yang, J.; Lin, J.; Guo, L. Renewable-biomolecule-based full lithium-ion batteries. Adv. Mater. 2016, 28, 3486–3492.

Sheng, Z. H.; Shao, L.; Chen, J. J.; Bao, W. J.; Wang, F. B.; Xia, X.-H. Catalyst-free synthesis of nitrogen-doped graphene via thermal annealing graphite oxide with melamine and its excellent electrocatalysis. ACS Nano 2011, 5, 4350–4358.

Reddy, A. L. M.; Srivastava, A.; Gowda, S. R.; Gullapalli, H.; Dubey, M.; Ajayan, P. M. Synthesis of nitrogen-doped graphene films for lithium battery application. ACS Nano 2010, 4, 6337–6342.

Pels, J. R.; Kapteign, F.; Moulign, J. A.; Zhu, Q.; Tomas, K. M. Evolution of nitrogen functionalities in carbonaceous materials during pyrolysis. Carbon 1995, 33, 1641–1653.

Su, F. B.; Poh, C. K.; Chen, J. S.; Xu, G. W.; Wang, D.; Li, Q.; Lin, J. Y.; Lou, X. W. Nitrogen-containing microporous carbon nanospheres with improved capacitive properties. Energy Environ. Sci. 2011, 4, 717–724.

Wu, Z. S.; Ren, W. C.; Xu, L.; Li, F.; Cheng, H. M. Doped graphene sheets as anode materials with superhigh rate and large capacity for lithium ion batteries. ACS Nano 2011, 5, 5463–5471.

Bulusheva, L. G.; Okotrub, A. V.; Kurenya, A. G.; Zhang, H. K.; Zhang, H. J.; Chen, X. H.; Song, H. H. Electrochemical properties of nitrogen-doped carbon nanotube anode in Li-ion batteries. Carbon 2011, 49, 4013–4023.

Wu, G.; Dai, C. S.; Wang, D. L.; Li, D. Y.; Li, N. Nitrogen-doped magnetic onion-like carbon as support for Pt particles in a hybrid cathode catalyst for fuel cells. J. Mater. Chem. A 2010, 20, 3059–3068.

Bulusheva, L. G.; Okotrub, A. V.; Kinloch, I. A.; Asanov, I. P.; Kurenya, A. G.; Kudashov, A. G.; Chen, X.; Song, H. Effect of nitrogen doping on Raman spectra of multi-walled carbon nanotubes. Phys. Status Solidi B 2008, 245, 1971–1974.

Cuesta, A.; Dhamelincourt, P.; Laureyns, J.; Martínez-Alonso, A.; Tascón, J. M. D. Raman microprobe studies on carbon materials. Carbon 1994, 32, 1523–1532.

Sharifi, T.; Nitze, F.; Barzegar, H. R.; Tai, C.-W.; Mazurkiewicz, M.; Malolepszy, A.; Stobinski, L.; Wågberg, T. Nitrogen doped multi walled carbon nanotubes produced by CVD-correlating XPS and Raman spectroscopy for the study of nitrogen inclusion. Carbon 2012, 50, 3535–3541.

Sjöström, H.; Stafström, S.; Boman, M.; Sundgren, J. E. Superhard and elastic carbon nitride thin films having fullerenelike microstructure. Phys. Rev. Lett. 1995, 75, 1336–1339.

Maldonado, S.; Morin, S.; Stevenson, K. J. Structure, composition, and chemical reactivity of carbon nanotubes by selective nitrogen doping. Carbon 2006, 44, 1429–1437.

Liu, X. H.; Zhang, J.; Guo, S. J.; Pinna, N. Graphene/N-doped carbon sandwiched nanosheets with ultrahigh nitrogen doping for boosting lithium-ion batteries. J. Mater. Chem. A 2016, 4, 1423–1431.

Xiang, X. X.; Liu, E. H.; Huang, Z. Z.; Shen, H. J.; Tian, Y. Y.; Xiao, C. Y.; Yang, J. J.; Mao, Z. H. Microporous carbon derived from polyaniline base as anode material for lithium ion secondary battery. Mater. Res. Bull. 2011, 46, 1266–1271.

Stejskal, J.; Trchová, M.; Hromádková, J. I.; Kovárová, J.; Kalendová, A. The carbonization of colloidal polyaniline nanoparticles to nitrogen-containing carbon analogues. Polym. Int. 2010, 59, 875–878.

Yuan, D. S.; Zhou, T. X.; Zhou, S. L.; Zou, W. J.; Mo, S. S.; Xia, N. N. Nitrogen-enriched carbon nanowires from the direct carbonization of polyaniline nanowires and its electrochemical properties. Electrochem. Commun. 2011, 13, 242–246.

Li, L. M.; Liu, E. H.; Yang, Y. J.; Shen, H. J.; Huang, Z. Z.; Xiang, X. X. Nitrogen-containing carbons prepared from polyaniline as anode materials for lithium secondary batteries. Mater. Lett. 2010, 64, 2115–2117.

Youn, D. H.; Heller, A.; Mullins, C. B. Simple synthesis of nanostructured Sn/nitrogen-doped carbon composite using nitrilotriacetic acid as lithium ion battery anode. Chem. Mater. 2016, 28, 1343–1347.

Qin, J.; He, C. N.; Zhao, N. Q.; Wang, Z. Y.; Shi, C. S.; Liu, E. Z.; Li, J. J. Graphene networks anchored with Sn@graphene as lithium ion battery anode. ACS Nano 2014, 8, 1728–1738.

Zhang, G. H.; Zhu, J.; Zeng, W.; Hou, S. C.; Gong, F. L.; Li, F.; Li, C. C.; Duan, H. G. Tin quantum dots embedded in nitrogen-doped carbon nanofibers as excellent anode for lithium-ion batteries. Nano Energy 2014, 9, 61–70.

Zhang, N.; Zhao, Q.; Han, X. P.; Yang, J. G.; Chen, J. Pitaya-like Sn@C nanocomposites as high-rate and long-life anode for lithium-ion batteries. Nanoscale 2014, 6, 2827–2832.

Hassoun, J.; Derrien, G.; Panero, S.; Scrosati, B. A nanostructured Sn-C composite lithium battery electrode with unique stability and high electrochemical performance. Adv. Mater. 2008, 20, 3169–3175.

Sun, J. H.; Xiao, L. H.; Jiang, S. D.; Li, G. X.; Huang, Y.; Geng, J. X. Fluorine-doped SnO2@graphene porous composite for high capacity lithium-ion batteries. Chem. Mater. 2015, 27, 4594–4603.

Acknowledgements

The authors acknowledge the financial support from the National Natural Science Foundation of China (Nos. U1201241, 11375020, 51431001, and 21321001).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Chang, X., Wang, T., Liu, Z. et al. Ultrafine Sn nanocrystals in a hierarchically porous N-doped carbon for lithium ion batteries. Nano Res. 10, 1950–1958 (2017). https://doi.org/10.1007/s12274-016-1381-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-016-1381-6