Abstract

Over the last three decades, virus-like particles (VLPs) have evolved to become a widely accepted technology, especially in the field of vaccinology. In fact, some VLP-based vaccines are currently used as commercial medical products, and other VLP-based products are at different stages of clinical study. Several remarkable advantages have been achieved in the development of VLPs as gene therapy tools and new nanomaterials. The analysis of published data reveals that at least 110 VLPs have been constructed from viruses belonging to 35 different families. This review therefore discusses the main principles in the cloning of viral structural genes, the relevant host systems and the purification procedures that have been developed. In addition, the methods that are used to characterize the structural integrity, stability, and components, including the encapsidated nucleic acids, of newly synthesized VLPs are analyzed. Moreover, some of the modifications that are required to construct VLP-based carriers of viral origin with defined properties are discussed, and examples are provided.

Similar content being viewed by others

Introduction

Virus-like particles (VLPs) are multisubunit self-assembly-competent protein structures with identical or highly related overall structure to their corresponding native viruses [1]. The term “VLP” has been used to describe a number of biological objects, such as uncharacterized structures with viral morphology that are found in biological samples, empty structures of viral origin that are not composed of nucleic acids, infectious viruses with chemically or genetically introduced structure modifications and noninfectious, self-assembled gene products resulting from the cloning and expression of viral structural genes in heterologous host systems. A cumulative search for the term “virus-like,” which is the most accepted name for these particles, in Google Scholar yielded 15,700 publication records through 1995, approximately 42,000 through 2005, and at least 102,000 publications through the middle of 2012. These data demonstrate the continuously increasing interest of scientists and technologists in different aspects of VLP-based technologies.

The interest in new VLPs was largely inspired by the successful development and introduction of the hepatitis B virus (HBV) surface antigen [2] and the human papilloma virus (HPV) capsid protein L1 [3] as commercial vaccines against hepatitis B and HPV-induced cervical cancer, respectively. Recently, several VLP-based vaccine candidates have entered different stages of clinical investigations with the aim to develop VLP-based vaccines for medical and veterinary purposes in the near future [4, 5].

The results of numerous studies suggest the high-immune response-stimulating activity of VLPs and demonstrate the B cell activation and high-titer antibody production that is triggered by the surface-displayed, structured and densely repeated amino acid (AA) motifs of the VLPs [6, 7]. In addition, the nanometer-sized VLPs can be taken up by antigen-presenting cells and degraded, which ultimately leads to T cell activation [8]. Moreover, due to their symmetric and highly repetitive AA structures, VLPs are capable of inducing strong humoral and cellular immune responses even in the absence of frequently used adjuvants [9].

VLPs have great potential for a number of applications in addition to vaccines. The treatment of many hereditary and acquired genetic disorders by different gene therapy tools is one of the most important challenges that are being addressed through the progress of nanotechnology. Comparisons of different nanocontainers suggest that icosahedral, filamentous, and lipid-enveloped virus-like vectors are the most promising gene carriers [10]. The current success of gene therapy is largely based on viral vectors and synthetic liposomes, although both have a number of limitations, such as restricted packaging capacity, production difficulties, and undesirable immunological properties. However, due to their construction flexibility, VLPs can be engineered to overcome these disadvantages, which include the use of chemical modifications to reduce unwanted immunological responses after repeated use [11].

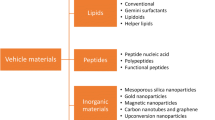

In addition to the potential applications of VLPs as vaccines and gene therapy tools, particular interest has recently been paid to the development of new nanomaterials that are composed of different viruses and VLPs. This new area of biotechnology, which is called bionanotechnology, represents a broad multidisciplinary approach that employs concepts and methodologies from biology, chemistry, physics, and engineering [12]. As new nanomaterials, viruses and VLPs possess several advantages over the products that are produced by chemical synthesis, including their size, which ranges from 10 to 2000 nm, the availability of high-resolution three-dimensional (3D) models of their structure, their construction flexibility through chemical and molecular biological techniques, their high- production yields in natural and/or heterologous hosts, and the structural uniformity of each type of virus or VLP [13].

Narrowly, VLPs can also be defined as replication-incompetent macromolecular protein assemblies that consist of one or several structural proteins of different viruses and can be obtained from recombinant organisms via the expression of the corresponding cloned genes [14]. This review summarizes the publicly available data on VLPs from recombinant sources and discusses the main principles and methods that are used to construct and characterize these macromolecular assemblies. In some cases, examples from experiments that use native viral structural proteins as a source of VLPs are included to demonstrate the remarkable ideas and techniques that are used to obtain and characterize VLPs. Information on replication-competent VLPs and synthetic nanoparticles with virus-like properties can be found in other review articles [1, 15, 16].

Recombinant VLPs

Since the beginning of the 1980s, over 100 VLPs that originated from microbial, plant, insect, and mammalian viruses have been constructed and characterized. The aim of these studies was to use these particles for a variety of purposes, from basic virus assembly and structure studies to the production of commercial human and animal vaccines. Examples of VLPs from 35 different virus families, which are grouped according to the structure of their encapsidated nucleic acids, are summarized in Tables 1, 2, 3, 4. A list of the 110 published VLPs that were used for the data analysis in this review, along with their expression systems, properties and application examples, can be found in Supplemental Tables 1–4. The supplemental data are grouped according to the hosts from which the native viruses were isolated (bacterial, plant, mammalian, and other VLPs).

Cloning and Expression of Viral Structural Genes

Historically, the first recombinant VLPs were obtained from synthesized and cloned coat protein (CP) genes from the HBV core antigen (HBcAg) [17], the HBV surface antigen (HBsAg) [18], and the Tobacco mosaic virus (TMV) [19]. The first visualization of recombinant VLPs using electron microscopy was published in 1982, which demonstrated that the HBcAg VLPs were indistinguishable from the core shells that were isolated from an HBV-infected liver [20].

These first examples established several important ground rules for the construction of recombinant VLPs: (i) the construction of recombinant VLPs is largely based on several years (or even tens of years) of basic research on the corresponding virus; (ii) the necessary coding nucleic acids for the carrier coat protein(s) and for foreign functional peptides can be obtained synthetically from the aligned oligonucleotides; (iii) the foreign peptides can be inserted or added to the virus-based carrier molecule without influencing the self-assembly; (iv) VLPs can be obtained from heterologous hosts; and (v) newly constructed recombinant VLPs have significant advantages over native viruses, such as their availability in nearly unlimited amounts and similar or even better functional properties.

The first stage of VLP construction is the cloning of the necessary structural genes. Clinical or veterinary specimens, as well as some environmental samples, such as infected plant or microorganism cells, typically serve as the source of these genes. Taking into account the fact that over 1,500,000 nucleotide sequence records can be found after a search of the Entrez site (The Life Science Search Engine, NCBI) using the keyword “virus,” the sequence of the viral structural protein of interest can likely be found in the databases. In most cases, this sequence is sufficient to use oligonucleotides for the gene synthesis in the absence of infected material. It should be noted that the gene synthesis permits the inclusion of typical AA codons for the heterologous host in the target gene, which enhances the expression level of the target protein. Alternatively, at least in the case of E. coli, the usage of special host strains that synthesize rare AA codon-recognizing tRNAs can stimulate the efficient synthesis of the VLPs from their original sequence [21]. Typically, all known VLPs are derived from viruses that are well characterized, at least at the level of full-length nucleotide sequence and genome organization.

Due to the vast amount of information that is available on different VLPs, it is not possible to analyze the details of the cloning of the viral structural genes in each case. Tables 1, 2, 3, 4 contain the list of structural genes for each virus family, the expressed genes that are necessary for the construction of the respective VLPs and examples with citations.

Expression Host Systems

One of the crucial factors in the construction of new VLPs is the choice of expression system. The analysis of the published reports on the successful construction of 174 VLP (Supplemental Tables 1–4) indicates that bacterial systems are used in 28 % of the cases, particularly for the production of bacterial and plant VLPs. The yeast (20 %) and insect systems (28 %) are more universal, and these expression hosts have been successfully used for the construction of VLPs from different sources. Plant (9 %) and mammalian hosts (15 %) are typically used to insure the production of VLPs with specific properties.

Bacterial Systems

Bacterial systems are mostly based on well-characterized commercial Escherichia coli strains and expression vectors. Despite their disadvantages, such as their inability to produce recombinant proteins with post-translational modifications, their inability to generate the proper disulfide bonds, the protein solubility problems, and the presence of endotoxins in the preparations of recombinant proteins. E. coli systems are a generally accepted technology that satisfies many research and industrial requirements and have been widely used for VLP production. A successful VLP production using E. coli is likely achievable in cases in which the target VLPs contain only one coat protein (CP; see Tables 1, 3, 4) that is soluble in the cells after cultivation. However, recombinant proteins, especially those that originate from eukaryotic hosts, are often insoluble in E. coli systems. As demonstrated with the parvovirus B19 [22] and the CCMV [23] and CMV [24] plant viruses, viral CPs can also be efficiently produced in the form of insoluble inclusion bodies, purified under denaturing conditions, refolded, and self-assembled. Moreover, the self-assembly of VLPs in E. coli cells can be initiated by the simultaneous coexpression of a specific RNA structure, e.g., origin of assembly, with the CP gene [25].

However, a simple change in the cultivation conditions can solve the problem of inclusion bodies. Low-temperature cultivations, which are rather atypical for E. coli, may stimulate the formation of soluble VLPs, as shown in the case of the densovirus IHHNV [26] and the potyvirus PVY [27]. In addition, several factors, such as the resistance markers of the expression plasmids and the composition of the cultivation medium, can influence the assembly of VLPs, as demonstrated with the bacteriophage Qβ VLPs [28].

E. coli cells have also been used for the complicated production of VLPs that require more than one type of structural protein for their formation. After the cloning and expression in E. coli of the avibirnavirus IBDV VP2-, VP4-, and VP3-containing polyprotein gene (Table 3), the polyprotein was cotranslationally autoprocessed by protease VP4 activity, which enables the formation of immunologically active VLPs in bacterial cells [29]. However, as shown with the plant virus MRFV, the inclusion of the corresponding protease gene in the expression cassette is not always necessary; the synthesis of these VLPs can be achieved through the simple coexpression of two engineered CP genes from a single expression vector [30].

Another approach that can be used to achieve higher expression levels and solubility involves the usage of different fusion protein systems. The papillomavirus HPV L1 protein was obtained from recombinant E. coli cells in the form of a glutathione-S-transferase (GST) fusion protein, and the VLP assembly of the L1 protein was completed after the GST section was removed with thrombin. The quality of the resulting particles was sufficient to obtain L1 crystals for subsequent X-ray crystallographic analysis, which resulted in the construction of a 3D model of T = 1 icosahedral HPV L1 particles [31]. This fusion protein strategy has also been successfully exploited with the polyomavirus MuPyV [21, 32] and the picornavirus FMDV [33] VLPs. When the N-terminal part of the CP is located on the VLP surface, the N-terminally added short peptides, such as His-tag or small protein epitopes, do not influence the particle formation and can be directly introduced into the VLP structure without proteolytic cleavage and reassembly in vitro [27, 34].

Other prokaryotic organisms can also be used for VLP production. For example, Lactobacillus has been used for the production of the HPV L1 protein to generate edible vaccine candidates [35], and Pseudomonas was used to improve the low solubility of the CP of CCMV [36].

Yeast Systems

Since the first successful experiments with HBV surface protein, which led to the production of commercial prophylactic vaccines against hepatitis B and the use of HPV L1 VLPs as a vaccine against cervical cancer, different yeast systems have been used for the construction of numerous VLPs, including the expression of viral structural genes of bacterial [37–39], yeast [40, 41], plant [42, 43], and mammalian [18, 44–48] origin (see also Supplemental Tables). Yeast expression systems, especially those that are based on Pichia and Hansenula strains, are more complicated than E. coli expression systems from the point of view of construction because yeast shuttle-vectors have to first be prepared in bacteria and then introduced into the yeast cells as plasmid vectors or selected to obtain stable yeast recombinants with a genome-integrated transgene.

Comparative studies of the yeast expression systems revealed the efficiency of Pichia in the production of RNA bacteriophage VLPs. However, this production results in approximately 30 % of the yield that is obtained in E. coli, as was observed with the Qβ VLPs [38]. A yeast system can also be used for the packaging of functional heterologous mRNA in bacteriophage MS2 VLPs if the simultaneous synthesis of the CP and the mRNA of the model protein is accomplished from the same expression vector. In this case, the design of the expression cassette requires the presence of special packaging RNA sequence that is found in the native MS2 genome [37]. However, these packaging signals are not always necessary for the formation of VLPs in yeast cells. The Saccharomyces expression system produces soluble CCMV VLPs that contain mostly host-derived RNA [43], which is contrary to the E. coli-based expression system, in which the CPs form inclusion bodies.

Another advantage of yeast systems is the possibility of introducing post-translational modifications, such as glycosylation or phosphorylation, to the VLP structure, as shown with the hepatitis B VLPs [44, 47]. Similar to the VLPs from recombinant bacteria, successful multigene expression systems have also been constructed in yeasts. The expression of three rotavirus structural genes (Table 3) from a single plasmid vector lead to the formation of triple-layered VLPs in S. cerevisiae cells [48]. However, in the case of enveloped viruses, such as HIV-2, S. cerevisiae cells do not support the multimerization of the Gag protein into VLPs and particle budding, which suggests that yeast does not contain the necessary host factors [49]. It is important to note that VLP formation does not always take place during the cultivation process of the yeast cells. Experiments with HBsAg from Pichia suggest that the self-assembly of the VLPs should be completed during the purification of the target product [50].

Insect Systems

Insect cell-based expression systems are widely used for VLP production on the laboratory or industrial scale due to a number of advantages, such as the fast growth rates in animal product-free media, the capacity for large-scale cultivations, and the ability of post-translationally modifying the recombinant proteins similarly to mammalian cells [51]. The insect cell line derived from Trichoplusia ni is used for the production of the commercial HPV L1-VLP vaccine. In addition, at least 7 additional VLPs that are isolated from recombinant insect cells are at different stages of development as vaccine candidates [52].

For the expression of foreign viral protein genes in insect cells, the construction of vectors based on the modified baculoviruses is necessary. To obtain VLPs that contain more than one structural protein, insect cell lines are infected with multiple different monocistronic baculoviruses (coinfection) or with a single polycistronic baculovirus (coexpression). The coinfection strategy is the more accepted approach because it allows the manipulation of the relative expression levels of the corresponding structural proteins [53]. Moreover, this strategy allows the identification of the proteins that are necessary for VLP formation. Using a coinfection methodology, 6 different proteins have been shown to be simultaneously expressed and self-assembled into VLPs within the same cell, as demonstrated with the herpesvirus HSV [54]. The coexpression strategy was also shown to be effective in the construction of some VLPs, including those derived from influenza, using a tricistronic baculovirus with a triplicated polyhedron promoter [55] or even a quadrupole baculovirus with three polyhedrin and one p10 promoter [56].

The construction of VLPs from viruses with a polyprotein genome organization can be accomplished through the cloning of the whole polyprotein gene into the baculovirus vector. The polyprotein strategy has been successfully used in the case of the alphavirus SAV. The concerted action of the alphavirus protease from the polyprotein and the host-derived proteases at atypically low-cell culture cultivation temperatures are crucial factors for the formation and maturation of the VLP [57]. Similar results using the polyprotein cleavage approach were obtained with the plant virus CPMV [58]. As demonstrated in experiments with the entorovirus-71 VLPs, the polyprotein strategy can be more efficient in terms of VLP yields than the coinfection method [59].

Interestingly, baculovirus-based vectors can also be used with the whole insect larvae, including silkworm larvae [51], as a cheaper alternative to produce VLPs [60]. The most recent baculovirus-silkworm multigene expression system insures the simultaneous expression of six different transgenes from a single recombinant baculovirus [61].

Plant Systems

Initially, the attempts to generate VLPs in whole transgenic or natural plants with different transient expression vectors were tightly bound to the idea of edible vaccines. However, modern medical concepts require precisely formulated vaccine products and supervised administration to insure reproducible effects, which has made injectable vaccines more acceptable [62]. Despite the revision of the concept, plant systems remain a cost-effective and scalable alternative for the production of different medicinal proteins, including vaccines [63]. Some recent developments, such as the Norwalk VLPs that were manufactured under Good Manufacturing Practice (GMP) conditions for subsequent clinical trials [64] and the results of the first human trials of edible vaccines [65], continue to support the idea that VLPs from plant sources can be used as vaccines and suggest the necessity for further research in this area.

The principles for the construction of VLPs in different plant expression systems, the successful production of VLPs in plants and the self-assembly of numerous viral structural proteins in plant hosts are extensively discussed in several review articles [63, 66, 67]. As an example, one of the most effective plant expression systems is based on the Agrobacterium-mediated transfer of a tobamovirus-derived expression vector in whole plant cells, which resulted in yields of up to 3 g of recombinant VLPs per kg of leaf biomass [68].

It should be mentioned that plant hosts that are infected with native viruses can serve as a source of assembly-competent viral structural proteins for the construction of new nanomaterials [69].

Mammalian Cell Systems

For over two decades, the use of mammalian cell cultures as a source of commercial therapeutic proteins has been developed [70]. Taking advantage of the product authenticity and the correct glycosylation pattern that are obtained with this system, more than half of all of the recombinant proteins in the pharmaceutical industry are produced in different mammalian cell lines [71]. Despite the complexity in the construction and practical applications, mammalian cell line systems are widely used for VLP production both in basic experiments and on the industrial scale with the aim to construct vaccine candidates and gene therapy agents. Different mammalian cells are especially efficient hosts for the construction of complex enveloped viruses, including influenza viruses. If a stable mammalian cell line expressing four influenza structural proteins is constructed, it is possible to create hybrid VLPs that contain matrix proteins from one influenza type (H3N2) and surface glycoproteins from another type (H5N1) [72]. This system would allow the generation of correctly glycosylated VLPs, which are similar in size to the native viruses, with encapsidated host cellular proteins and high-immunological activity. The most complicated system that has been developed to obtain VLPs was shown with influenza viruses. A cell line that was infected with recombinant vaccinia virus vector that expresses the T7 polymerase and transfected with bacterial plasmids containing the cDNAs of all ten influenza virus proteins was able to produce VLPs. Moreover, the model protein mRNA after cDNA transcription was rescued into the influenza VLPs [73].

The polyprotein strategy, which was described above, can also be used in mammalian cells. The polyprotein cDNA that encodes all of the structural proteins of the alphavirus CHIKV was cloned into a eukaryotic expression vector, which was then introduced into a human cell line; the resultant cells produced CHIKV VLPs, as demonstrated through immunological and electron microscopy analyses [74]. Interestingly, these experiments demonstrated that the CHIKV VLPs are able to elicit stronger antibody responses than the corresponding DNA vaccines [74].

Cell-Free Systems

Crude cell extracts have been used as a tool for protein synthesis for over 50 years. In the past, cell-free protein synthesis (CFPS) was mostly used in basic studies of the transcription and translation mechanisms, as well as for the rapid evaluation of different expression systems. In recent years, the development of CFPS has reached the stage of an independent expression system with potential industrial significance. CFPS systems based on E. coli, wheat germs, insect cells, and rabbit reticulocytes are now commercially available. The most popular is the E. coli-derived CFPS due to the simple preparation of the extract and the comparably high yields of the desired proteins [75]. Recently, the synthesis of the RNA bacteriophage MS2-, Qβ-, and HBV core-derived VLPs has been demonstrated using E. coli-based CFPS technology. In the case of the Qβ VLPs, the CFPS allows the incorporation of the A2 protein, which is toxic for living cells [76], whereas the production of the HBcAg, MS2 and Qβ VLPs in the chosen cell-free system provides considerable stabilization of the particles through the introduction of disulfide bonds [77]. It is notable that the yield of the VLPs is almost 1 mg/ml and the efficiency of the VLP assembly exceeds 80 % in the case of HBcAg and Qβ. These proof of concept experiments using well-established VLP models suggest that CFPS can also be used with more complicated cases, especially when the expression of the viral structural protein genes is toxic for living cells or if the conditions for the traditional systems do not allow the production of VLPs with the desired properties, e.g., when the incorporation of unnatural amino acids is necessary [78].

Purification and Characterization

To insure that the constructed and synthesized VLPs remain intact for the intended downstream applications, the selection of the correct purification scheme is of the utmost importance. The VLP purification and characterization is largely based on experience that has been obtained in experiments with different viruses. Therefore, the initial conditions for the development of a purification protocol for a newly constructed and uncharacterized VLP can be based on those used with the corresponding native virus. In this section, the most important methods that are currently used in VLP purification, identification, and characterization will be reviewed.

Purification

Because VLPs have been industrial products for over two decades, the general principles of VLP purification are well known and include the following steps: (i) the lysis of the cell to transfer the synthesized VLPs to the solution; (ii) the clarification process to insure the removal of cell debris and other large aggregates; (iii) the concentration step; and (iv) the polishing step to remove the residual host or target product-derived impurities [79].

The cell lysis is a very important step in VLP purification. However, because many mammalian and insect cell systems insure the secretion of the VLPs into the culture supernatants, the cell lysis step is not always necessary [52]. The VLPs produced in non-secreting systems require the use of a suitable approach to prepare the cell-free extract. For example, the simple treatment of eukaryotic cells with detergent-containing solutions is sufficient. In contrast, bacterial, yeast, and plant cells require strong mechanical treatment, such as various mills or French presses, ultrasonication, grinding with abrasives (e.g., aluminum oxide), repeated freezing/thawing cycles, and enzymatic treatments [80, 81]. For the purification of uncharacterized VLPs with unknown stability properties, different cell lysis protocols and extraction buffer compositions are tested to identify the optimal method that preserves the integrity of particles.

To protect the VLPs from oxidation and host proteases during the purification process, the extraction buffers are often supplemented with reducing and chelating agents and protease inhibitors. In addition, nucleases are sometimes added at this stage to reduce the amount of host nucleic acids in the extracts. After clarification by low-speed centrifugation or ultrafiltration, the VLP-containing solutions have to be further concentrated and purified. A number of viruses and VLPs are stable enough to withstand precipitation with ammonium sulfate and/or polyethylene glycol (PEG). The precipitation significantly decreases the volume of the extract and the amount of host-derived impurities, which ultimately results in a reduced number of subsequent centrifugal and chromatography purification steps. In laboratory-scale purifications, further VLP purification by ultracentrifugation in CsCl or sucrose gradients is often sufficient to obtain suitable preparations for subsequent applications, especially when successive rounds of low- and high-speed centrifugations are applied. In industrial-scale processes, the use of ultracentrifugation has some restrictions due to the risk of VLP aggregation, the lack of scalability, and the enhancement of labor intensity [52]. Thus, instead of using ultracentrifugation, the necessary purity of VLPs is often achieved through special chromatographic processes. Depending on the properties of the VLP, different size-exclusion, ion exchange, and affinity columns are used in the purification process. However, additional steps, such as the treatment of the VLP solution with diatomic earth before the column chromatography, may be necessary to achieve the desired vaccine-grade purity level, as demonstrated with the production of HBsAg in Pichia [82].

The purification schemes not only include the removal of host or target product-derived impurities from VLPs. In special cases, to improve the functional properties of the target VLPs, a disassembly/reassembly stage is necessary. For example, reassembled human papilloma VLPs exhibit enhanced immunoreactivity and stability properties [83].

Characterization of VLPs

It is necessary to emphasize the methods that allow the identification of the VLP during the initial stages of construction. Different VLP properties can be useful for early detection and screening, and the methods partially overlap with those used in the purification. The application of PEG or ammonium sulfate, which have the ability to bind water molecules, until the solubility level of the VLP is exceeded can be used to precipitate high-molecular VLPs and leave the low-molecular impurities in the extract solution [84]. The purity of the precipitate is usually sufficient for simple downstream analysis to identify the VLP structural proteins by SDS/PAGE, agarose gel retardation tests of protein-nucleic acid complexes, which are typically used for VLPs [36, 85], and sucrose gradient and size-exclusion chromatography for demonstrations of the high-molecular state of the VLPs [86]. Alternatively, if the precipitation conditions can disassemble the particles, the VLP-containing extracts can be directly concentrated by ultracentrifugation. If mono- or polyclonal antibodies against corresponding native virus or VLPs are available, additional proofs of the VLP formation can be obtained using ELISA, Western blots [87], and immune diffusion tests as Ouchterlony’s double radial immune diffusion in agarose [38]. An electron microscopy analysis is necessary as a final visual proof of the new synthesized VLPs because above-mentioned indirect tests may identify large, unstructured protein aggregates as VLPs.

After purification, the different properties of the target VLPs have to be tested to demonstrate their accordance with the indented downstream applications. A valuable tool in the analysis of the VLP composition is mass spectrometry, which allows the measurement of the molecular mass of the assembled proteins. This technique has been used to identify proteolytically degraded [27] or post-translationally modified [44] proteins in the VLP structure. In the analysis of the glycosylation pattern of mammalian VLPs, the lectin-based glycan differentiation assay is a useful and rapid method for the identification of structural protein modifications [88]. The structural integrity of the VLPs can also be demonstrated by trypsin treatments in the presence or absence of detergents that are capable of dissociating the VLP-forming subunits [88].

Different VLP physical parameters are significant factors in the development of new identification methods and applications. The VLP concentration measurements can be complicated due to the protein/nucleic acid content of the particles. Nevertheless, simple but accurate concentration measurements based on UV spectra are available for the plant virus BMV and HBcAg VLPs; these are also applicable for other viruses and VLPs [89]. In addition, isoelectric point measurements by capillary isoelectric focusing have been found to be useful in the differentiation of the VLPs from different norovirus genogroups [90].

In complicated cases, immune and electron cryomicroscopy images can provide the necessary proof of the correctness of the constructed VLPs. Immunoelectron microscopy using colloidal gold that is conjugated to the antibodies has been widely used in VLP research and has been found to be necessary for the visualization and localization of antigens on the VLP surface. Electron cryomicroscopy provides images with comparably high resolution and has been used in a number of cases, including bluetongue [91], HIV-1 [92], HCV [93], CHIKV [94], and other VLPs. This method is also useful for the visualization of the displayed foreign peptides on the VLP surface [95]. More detailed information on electron microscopy and additional examples can be found in other review articles [96, 97]. Crystallization and subsequent X-ray structure analysis is usually applied for further resolution characterization of the VLP properties. VLPs are also used in cases in which the corresponding native viruses are not available in preparative amounts and in stepwise virus assembly studies [98–101].

Because VLPs are mostly produced for different downstream applications, the stability of the recombinant particles is one of the most significant issues. Another important reason to perform stability experiments is the necessary determination of the conditions that support the disassembly of the particles for subsequent reassembly and packaging of the foreign agents, such as proteins, nucleic acids, and low-molecular mass compounds. To obtain data on their stability, the purified VLPs are incubated in different buffer solutions and/or at elevated temperatures. One of the most popular methods that demonstrates the influence of the incubation conditions on the VLP structure is the above-mentioned native agarose gel analysis, which was used with the plant virus CCMV and the RNA bacteriophages Cb5, MS2, and PRR1 [36, 98, 99]. However, this method is only applicable when the VLPs contain nucleic acids and when the dimensions of the VLP are compatible with agarose gel analysis. For filamentous or empty VLPs, other methods can be appropriate, such as various spectroscopic techniques, which were used with Norwalk VLPs [102], and the detection of the appearance of low-molecular structures through the separation of the samples by ultracentrifugation [27]. In the case of norovirus, the mechanical stability of the corresponding VLPs was tested by atomic force microscopy [103]. For high-throughput analyses, the structural changes in the VLPs at elevated temperatures are monitored in the presence of Sypro-Orange dye using a real-time PCR system and a DNA melting point determination program [27]. In some cases, the results of the stability studies should be corrected by electron microscopy visualizations, as was necessary for the hybrid rod-like VLPs of the bacteriophages GA and fr [104].

If the conventional expression system does not insure the production of oxidized VLPs, the stability of the VLPs can be considerably enhanced through the introduction of disulfide bridges to crosslink the individual structural proteins with hydrogen peroxide in the cell-free system. As a result, disulfide bridges-containing Qβ VLPs can withstand temperatures of up to 75 °C, whereas reduced VLPs are only stable at a temperature of approximately 45 °C [77]. Simple additives can also enhance the VLP stability. From vaccine formulation studies, it is known that the addition of additives, such as polysorbate, sorbitol, and disaccharide trehalose, effectively prevents VLP aggregation [105, 106].

Viral structural proteins are typical nucleic acid-binding proteins. Numerous studies demonstrate the ability of recombinant VLPs to bind and encapsidate nucleic acids that are present in the host cells, such as the mRNA of the transgene, ribosomal and/or transport RNAs [88, 107–109]. In some cases, the mRNA of the cloned gene is not found in the VLPs [30]. DNA microarray experiments suggest that CCMV VLPs, along with its own mRNA, are capable of encapsidating a large number of Pseudomonas mRNAs, except for the ribosomal RNA, which is the most abundant cell RNA [36]. As was found in the case of FHV through the use of a next-generation sequencing technique, VLPs mostly encapsidate ribosomal RNA and the transcripts from the introduced baculovirus expression vectors. Interestingly, native FHV virions also exhibit the ability to package host RNAs, although these particles package only approximately 1 % of the total amount [110]. To identify the RNA secondary structures that are responsible for the encapsidation process, the SELEX system was recently developed for nucleic acid-binding tests with the plant virus STNV VLPs. After 10 rounds of selection, no single RNA stem loop was identified as a potential VLP assembly initiation site; instead, eight different secondary structures in the SNTV genome partially corresponded to the consensus sequence found by the SELEX method [111]. These data suggest a possible mechanism for host nucleic acid encapsidation in the recombinant VLPs: if the transcriptoma of the heterologous host with the cloned viral structural gene contains RNA(s) with the necessary secondary structures in sufficient amounts, these can serve as factors that stimulate or even initiate the VLP formation.

VLPs with Defined Properties

In many cases, the construction of VLPs is tightly bound with the aim to obtain structured multimeric protein assemblies with specific properties for subsequent applications. In the case of a successful construction, VLPs are to some extent “universal,” e.g., useful for different purposes with the same or a similar principle of action, which is highly important for the development of the technology platform. In this section, the examples of VLPs with noticeable universal properties are discussed.

First, VLPs can be used for different purposes based on their intrinsic properties without any changes to the structural proteins. Mammalian VLPs recognize cells from the corresponding organism and are able to deliver cargo, such as therapeutic nucleic acids or proteins, to the recipient organism [112, 113]. The ability to bind specific nucleic acids is common for viral structural proteins and is used for the binding and encapsidation of other negatively charged substances, such as oligonucleotides and biological and chemical polymers, as shown with the recombinant HBcAg, Qβ, and CCMV VLPs [114–116]. This binding property seems to be universal. However, the packaging is limited by the size of the negatively charged polymer. This limitation is apparently bound by the internal volume of the corresponding VLPs and the availability of positively charged AAs in the VLP structure. Therefore, the polyomavirus JC VLPs, which are gene therapy vector candidates, are able to package different plasmid DNAs in sizes that exceed 9 kbp but not 14.5 kbp during the cultivation of E. coli cells [117].

In addition to the packaging, VLP intrinsic properties, such as surface-located AA regions, can serve as targets for the introduction of various functional molecules. There are two general methods for introducing molecules into the carrier VLPs: chemical coupling and genetic fusion. In the chemical coupling process, any method that is known to modify a protein can be used provided that the conditions of the reaction preserve the structural integrity of the VLPs. In most cases, the surface-located lysine residues are targets for coupling [118], although other AAs, such as cysteine, tyrosine, aspartic, and glutamic acids, can also be modified [13]. Some VLPs are shown to possess nearly universal properties for chemical conjugation; one of the best-studied VLPs with this property is the plant virus CPMV [119]. Other VLPs, such as those derived from the bacteriophages Qβ and AP205 have been validated for the coupling of different antigens, including low-molecular substances, such as nicotine and whole proteins, with the aim to obtain prophylactic and therapeutic vaccines [120–123].

For VLPs without reactive AAs on the surface, the necessary universality can be achieved by targeted mutagenesis, as shown in the case of TMV. After the incorporation of an accessible lysine residue, the subsequent coupling of biotin moieties to the virus enabled the tight binding of 2,200 molecules of recombinant streptavidin-containing model protein per viral particle [124]. The introduction of AAs such as cysteine to some VLPs has been found to be useful for the subsequent coupling and multivalent display of ligands [125].

Genetic methods have been widely used for the introduction of different peptides, including immunologically relevant epitopes, to the VLP structure [1]. In addition, the introduction of specific peptides can contribute to the broadening of the potential VLP applications. Recently, the heterodimeric coiled-coil AA motifs were found to be useful for the packaging of different proteins in the VLP interior without chemical coupling or genetic fusions [126, 127]. The interaction between the coiled-coil motif-containing CCMV CP and the protein of interest insured a strong binding between the two components, which allowed the encapsidation of up to 14 molecules of the model protein inside the 28 nm CCMV particle.

The introduction of a whole protein into the VLP structure can also be achieved by genetic fusion, especially in the case of larger VLPs [112, 128]. A versatile system called SplitCore was recently developed for the HBcAg VLPs [129]. The splitting of the HBcAg gene at the encoded immunodominant region into two parts and the expression of both fragments in E. coli retained the ability of VLP formation. This system allows the display of several proteins of medicinal relevance, which have sizes of more than 300 AA, on the VLP surface. This splitting principle is also applicable to other VLPs [129].

Another interesting development that has made VLPs suitable for different applications is the incorporation of protein A-derived domains in the particle structure. These domains are known to effectively bind to the constant regions of the antibody molecules (IgG) of different organisms. After displaying this domain on the particle surface, the VLPs are able to bind up to 2 g of IgG per 1 g of carrier [130], which offers a simple procedure for the purification of different monoclonal antibodies. VLPs with protein A domains and bound antibodies can also be used for the addressed delivery of therapeutic nucleic acid to specific cells [131] or as sensitive diagnostic agents [132]. Other examples of multifunctional VLPs for protein delivery can be found in a recent review [133].

Concluding Remarks

The latest metagenomic evaluations suggest that virologists are using less than 1 % of the existing viral diversity [134]. Therefore, the environmental samples represent an inexhaustible source of new viral structural genes, from which new VLPs with defined properties can be constructed. However, the construction process of new VLPs is still expensive and labor-intensive. The use of mammalian expression systems is acceptable for the construction of structurally complicated VLPs, particularly if the introduction of the correct post-translational modifications and/or the production of VLPs that contain multiple structural proteins are necessary. As confirmed by numerous experiments, insect and yeast cell systems can be an effective alternative to mammalian hosts. However, when the construction of a new VLP is considered, E. coli hosts should first be tested because these hosts have lower costs and require a shorter construction time. Due to the absence of generally applicable, rapid screening methods and the inefficiency of in silico predictions, the only approach that can be used to construct new and modify existing VLPs is the trial and error method with subsequent visual confirmation by electron microscopy [135].

Taking into account the advances in vaccine development, VLPs have a positive reputation as systems of academic, industrial, and commercial significance and are no longer only “mere laboratory curiosities” [14]. However, in some fields, such as gene therapy and nanomaterials, the potential VLP application technologies are based only on laboratory experiments. The study of the most perspective VLP-based objects and applications must be continued to demonstrate the predictability, sustainability, and cost efficiency of this technology.

References

Pumpens, P., & Grens, E. (2002). Artificial genes for chimeric virus-like particles. In Y. E. Khudyakov & H. A. Fields (Eds.), Artificial DNA: Methods and applications (pp. 249–327). Boca Raton: CRC Press.

Pumpens, P., Ulrich, R., Sasnauskas, K., Kazaks, A., Ose, V., & Grens, E. (2009). Construction of novel vaccines on the basis of the virus-like particles: Hepatitis B virus proteins as vaccine carriers. In Y. E. Khudyakov (Ed.), Medicinal protein engineering (pp. 205–248). Boca Raton: CRC Press.

Frazer, I. H. (2004). Prevention of cervical cancer through papillomavirus vaccination. Nature Reviews Immunology, 4, 46–54.

Liu, F., Ge, S., Li, L., Wu, X., Liu, Z., & Wang, Z. (2012). Virus-like particles: Potential veterinary vaccine immunogens. Research in Veterinary Science, 93, 553–559.

Roldão, A., Mellado, M. C., Castilho, L. R., Carrondo, M. J., & Alves, P. M. (2010). Virus-like particles in vaccine development. Expert Review of Vaccines, 9, 1149–1176.

Bachmann, M. F., & Zinkernagel, R. M. (1997). Neutralizing antiviral B cell responses. Annual Review of Immunology, 15, 235–270.

Brun, A., Bárcena, J., Blanco, E., Borrego, B., Dory, D., Escribano, J. M., et al. (2011). Current strategies for subunit and genetic viral veterinary vaccine development. Virus Research, 157, 1–12.

Bachmann, M. F., & Dyer, M. R. (2004). Therapeutic vaccination for chronic diseases: A new class of drugs in sight. Nature Reviews Drug Discovery, 3, 81–88.

Bachmann, M. F., Rohrer, U. H., Kündig, T. M., Bürki, K., Hengartner, H., & Zinkernagel, R. M. (1993). The influence of antigen organization on B cell responsiveness. Science, 262, 1448–1451.

Lamarre, B., & Ryadnov, M. G. (2011). Self-assembling viral mimetics: One long journey with short steps. Macromolecular Bioscience, 8, 503–513.

Seow, Y., & Wood, M. J. (2009). Biological gene delivery vehicles: Beyond viral vectors. Molecular Therapy, 17, 767–777.

Soto, C. M., & Ratna, B. R. (2010). Virus hybrids as nanomaterials for biotechnology. Current Opinion in Biotechnology, 21, 426–438.

Lee, L. A., Niu, Z., & Wang, Q. (2009). Viruses and virus-like protein assemblies—chemically programmable nanoscale building blocks. Nano Research, 2, 349–364.

Pattenden, L. K., Middelberg, A. P., Niebert, M., & Lipin, D. I. (2005). Towards the preparative and large-scale precision manufacture of virus-like particles. Trends in Biotechnology, 23, 523–529.

Hoenen, T., Groseth, A., de Kok-Mercado, F., Kuhn, J. H., & Wahl-Jensen, V. (2011). Minigenomes, transcription and replication competent virus-like particles and beyond: Reverse genetics systems for filoviruses and other negative stranded hemorrhagic fever viruses. Antiviral Research, 91, 195–208.

Saccardo, P., Villaverde, A., & González-Montalbán, N. (2009). Peptide-mediated DNA condensation for non-viral gene therapy. Biotechnology Advances, 27, 432–438.

Burrell, C. J., MacKay, P., Greenaway, P. J., Hofschneider, P. H., & Murray, K. (1979). Expression in Escherichia coli of hepatitis B virus DNA sequences cloned in plasmid pBR322. Nature, 279, 43–47.

Valenzuela, P., Medina, A., Rutter, W. J., Ammerer, G., & Hall, B. D. (1982). Synthesis and assembly of hepatitis B virus surface antigen particles in yeast. Nature, 298, 347–350.

Haynes, J. R., Cunningham, J., von Seefried, A., Lennick, M., Garvin, R. T., & Shen, S. H. (1986). Development of a genetically-engineered, candidate polio vaccine employing the selfassembling properties of the tobacco mosaic virus coat protein. Biotechnology, 4, 637–641.

Cohen, B. J., & Richmond, J. E. (1982). Electron microscopy of hepatitis B core antigen synthesized in E. coli. Nature, 296, 677–678.

Chuan, Y. P., Lua, L. H., & Middelberg, A. P. (2008). High-level expression of soluble viral structural protein in Escherichia coli. Journal of Biotechnology, 20, 64–71.

Sánchez-Rodríguez, S. P., Münch-Anguiano, L., Echeverría, O., Vázquez-Nin, G., Mora-Pale, M., Dordick, J. S., et al. (2012). Human parvovirus B19 virus-like particles: In vitro assembly and stability. Biochimie, 94, 870–878.

Zhao, X., Fox, J. M., Olson, N. H., Baker, T. S., & Young, M. J. (1995). In vitro assembly of cowpea chlorotic mottle virus from coat protein expressed in Escherichia coli and in vitro-transcribed viral cDNA. Virology, 10, 486–494.

Xu, Y., Ye, J., Liu, H., Cheng, E., Yang, Y., Wang, W., et al. (2008). DNA-templated CMV viral capsid proteins assemble into nanotubes. Chemical Communications, 1, 49–51.

Hwang, D. J., Roberts, I. M., & Wilson, T. M. (1994). Expression of tobacco mosaic virus coat protein and assembly of pseudovirus particles in Escherichia coli. Proceedings of the National Academy of Science of the United States of America, 91, 9067–9071.

Hou, L., Wu, H., Xu, L., & Yang, F. (2009). Expression and self-assembly of virus-like particles of infectious hypodermal and hematopoietic necrosis virus in Escherichia coli. Archives of Virology, 154, 547–553.

Kalnciema, I., Skrastina, D., Ose, V., Pumpens, P. & Zeltins, A. (2011). Potato virus Y-like particles as a new carrier for the presentation of foreign protein stretches. Molecular Biotechnology. doi:10.1007/s12033-011-9480-9.

Brown, S. D., Fiedler, J. D., & Finn, M. G. (2009). Assembly of hybrid bacteriophage Qbeta virus-like particles. Biochemistry, 48, 11155–11157.

Rogel, A., Benvenisti, L., Sela, I., Edelbaum, O., Tanne, E., Shachar, Y., et al. (2003). Vaccination with E. coli recombinant empty viral particles of infectious bursal disease virus (IBDV) confer protection. Virus Genes, 27, 169–175.

Hammond, R. W., & Hammond, J. (2010). Maize rayado fino virus capsid proteins assemble into virus-like particles in Escherichia coli. Virus Research, 147, 208–215.

Chen, X. S., Garcea, R. L., Goldberg, I., Casini, G., & Harrison, S. C. (2000). Structure of small virus-like particles assembled from the L1 protein of human papillomavirus 16. Molecular Cell, 5, 557–567.

Middelberg, A. P., Rivera-Hernandez, T., Wibowo, N., Lua, L. H., Fan, Y., Magor, G., et al. (2011). A microbial platform for rapid and low-cost virus-like particle and capsomere vaccines. Vaccine, 29, 7154–7162.

Lee, C. D., Yan, Y. P., Liang, S. M., & Wang, T. F. (2009). Production of FMDV virus-like particles by a SUMO fusion protein approach in Escherichia coli. Journal of Biomedical Science, 16, 69.

Ju, H., Wei, N., Wang, Q., Wang, C., Jing, Z., Guo, L., et al. (2011). Goose parvovirus structural proteins expressed by recombinant baculoviruses self-assemble into virus-like particles with strong immunogenicity in goose. Biochemical and Biophysical Research Communications, 409, 131–136.

Cortes-Perez, N. G., Kharrat, P., Langella, P., & Bermúdez-Humarán, L. G. (2009). Heterologous production of human papillomavirus type-16 L1 protein by a lactic acid bacterium. BMC Research Notes, 2, 167.

Phelps, J. P., Dao, P., Jin, H., & Rasochova, L. (2007). Expression and self-assembly of cowpea chlorotic mottle virus-like particles in Pseudomonas fluorescens. Journal of Biotechnology, 128, 290–296.

Legendre, D., & Fastrez, J. (2005). Production in Saccharomyces cerevisiae of MS2 virus-like particles packaging functional heterologous mRNAs. Journal of Biotechnology, 117, 183–194.

Freivalds, J., Dislers, A., Ose, V., Skrastina, D., Cielens, I., Pumpens, P., et al. (2006). Assembly of bacteriophage Qbeta virus-like particles in yeast Saccharomyces cerevisiae and Pichia pastoris. Journal of Biotechnology, 123, 297–303.

Freivalds, J., Rūmnieks, J., Ose, V., Renhofa, R., & Kazāks, A. (2008). High-level expression and purification of bacteriophage GA virus-like particles from yeast Saccharomyces cerevisiae and Pichia pastoris. Acta Universitatis Latviensis, 745, 75–85.

Burns, N. R., Saibil, H. R., White, N. S., Pardon, J. F., Timmins, P. A., Richardson, S. M., et al. (1992). Symmetry, flexibility and permeability in the structure of yeast retrotransposon virus-like particles. EMBO Journal, 11, 1155–1164.

Powilleit, F., Breinig, T., & Schmitt, M. J. (2007). Exploiting the yeast L-A viral capsid for the in vivo assembly of chimeric VLPs as platform in vaccine development and foreign protein expression. PLoS ONE, 2(5), e415.

Krol, M. A., Olson, N. H., Tate, J., Johnson, J. E., Baker, T. S., & Ahlquist, P. (1999). RNA-controlled polymorphism in the in vivo assembly of 180-subunit and 120-subunit virions from a single capsid protein. Proceedings of the National Academy of Science of the United States of America, 96, 13650–13655.

Brumfield, S., Willits, D., Tang, L., Johnson, J. E., Douglas, T., & Young, M. (2004). Heterologous expression of the modified coat protein of Cowpea chlorotic mottle bromovirus results in the assembly of protein cages with altered architectures and function. Journal of General Virology, 85, 1049–1053.

Freivalds, J., Dislers, A., Ose, V., Pumpens, P., Tars, K., & Kazaks, A. (2011). Highly efficient production of phosphorylated hepatitis B core particles in yeast Pichia pastoris. Protein Expression and Purification, 75, 218–224.

Hofmann, K. J., Cook, J. C., Joyce, J. G., Brown, D. R., Schultz, L. D., George, H. A., et al. (1995). Sequence determination of human papillomavirus type 6a and assembly of virus-like particles in Saccharomyces cerevisiae. Virology, 209, 506–518.

Juozapaitis, M., Serva, A., Kucinskaite, I., Zvirbliene, A., Slibinskas, R., Staniulis, J., et al. (2007). Generation of menangle virus nucleocapsid-like particles in yeast Saccharomyces cerevisiae. Journal of Biotechnology, 130, 441–447.

Janowicz, Z. A., Melber, K., Merckelbach, A., Jacobs, E., Harford, N., Comberbach, M., et al. (1991). Simultaneous expression of the S and L surface antigens of hepatitis B, and formation of mixed particles in the methylotrophic yeast, Hansenula polymorpha. Yeast, 7, 431–443.

Rodríguez-Limas, W. A., Tyo, K. E., Nielsen, J., Ramírez, O. T., & Palomares, L. A. (2011). Molecular and process design for rotavirus-like particle production in Saccharomyces cerevisiae. Microbial Cell Factories, 10, 33.

Morikawa, Y., Goto, T., Yasuoka, D., Momose, F., & Matano, T. (2007). Defect of human immunodeficiency virus type 2 Gag assembly in Saccharomyces cerevisiae. Journal of Virology, 81, 9911–9921.

Lünsdorf, H., Gurramkonda, C., Adnan, A., Khanna, N., & Rinas, U. (2011). Virus-like particle production with yeast: Ultrastructural and immunocytochemical insights into Pichia pastoris producing high levels of the hepatitis B surface antigen. Microbial Cell Factories, 10, 48.

Kato, T., Deo, V. K., & Park, E. Y. (2012). Functional virus-like particles production using silkworm and their application in life science. Journal of Biotechnology & Biomaterials, S9, 001.

Vicente, T., Roldão, A., Peixoto, C., Carrondo, M. J., & Alves, P. M. (2011). Large-scale production and purification of VLP-based vaccines. Journal of Invertebrate Pathology, 107, S42–S48.

Sokolenko, S., George, S., Wagner, A., Tuladhar, A., Andrich, J. M., & Aucoin, M. G. (2012). Co-expression vs. co-infection using baculovirus expression vectors in insect cell culture: Benefits and drawbacks. Biotechnology Advances, 30, 766–781.

Tatman, J. D., Preston, V. G., Nicholson, P., Elliott, R. M., & Rixon, F. J. (1994). Assembly of herpes simplex virus type 1 capsids using a panel of recombinant baculoviruses. Journal of General Virology, 75(Pt 5), 1101–1113.

Pushko, P., Tumpey, T. M., Bu, F., Knell, J., Robinson, R., & Smith, G. (2005). Influenza virus-like particles comprised of the HA, NA, and M1 proteins of H9N2 influenza virus induce protective immune responses in BALB/c mice. Vaccine, 23, 5751–5759.

Latham, T., & Galarza, J. M. (2001). Formation of wild-type and chimeric influenza virus-like particles following simultaneous expression of only four structural proteins. Journal of Virology, 75, 6154–6165.

Metz, S. W., Feenstra, F., Villoing, S., van Hulten, M. C., van Lent, J. W., Koumans, J., et al. (2011). Low temperature-dependent salmonid alphavirus glycoprotein processing and recombinant virus-like particle formation. PLoS ONE, 6(10), e25816.

Saunders, K., Sainsbury, F., & Lomonossoff, G. P. (2009). Efficient generation of cowpea mosaic virus empty virus-like particles by the proteolytic processing of precursors in insect cells and plants. Virology, 393, 329–337.

Chung, Y. C., Huang, J. H., Lai, C. W., Sheng, H. C., Shih, S. R., Ho, M. S., et al. (2006). Expression, purification and characterization of enterovirus-71 virus-like particles. World Journal of Gastroenterology, 12, 921–927.

Molinari, P., Peralta, A., & Taboga, O. (2008). Production of rotavirus-like particles in Spodoptera frugiperda larvae. Journal of Virological Methods, 147, 364–367.

Yao, L., Wang, S., Su, S., Yao, N., He, J., Peng, L., et al. (2012). Construction of a baculovirus-silkworm multigene expression system and its application on producing virus-like particles. PLoS ONE, 7(3), e32510.

Rybicki, E. (2010). Plant-made vaccines for humans and animals. Plant Biotechnology Journal, 8, 620–637.

Zeltins, A. (2009). Plant virus biotechnology platforms for expression of medicinal proteins. In Y. E. Khudyakov (Ed.), Medicinal protein engineering (pp. 481–517). Boca Raton: CRC Press.

Lai, H., & Chen, Q. (2012). Bioprocessing of plant-derived virus-like particles of Norwalk virus capsid protein under current Good Manufacture Practice regulations. Plant Cell Reports, 31(3), 573–584.

Tacket, C. O. (2009). Plant-based oral vaccines: Results of human trials. Current Topics in Microbiology and Immunology, 332, 103–117.

Gomez-Lim, M. A. (2009). Production of pharmaceutical compounds in plants. In Y. E. Khudyakov (Ed.), Medicinal protein engineering (pp. 445–479). Boca Raton: CRC Press.

Mason, H. S., & Herbst-Kralovetz, M. M. (2012). Plant-derived antigens as mucosal vaccines. Current Topics in Microbiology and Immunology, 354, 101–120.

Gleba, Y., Klimyuk, V., & Marillonnet, S. (2007). Viral vectors for the expression of proteins in plants. Current Opinion in Biotechnology, 18, 134–141.

Lomonossoff, G. P. & Evans, D.J. (2011). Applications of Plant Viruses in Bionanotechnology. Current Topics in Microbiology and Immunology. doi:10.1007/82_2011_184.

Wurm, F. M. (2004). Production of recombinant protein therapeutics in cultivated mammalian cells. Nature Biotechnology, 22, 1393–1398.

Walsh, G. (2006). Biopharmaceutical benchmarks 2006. Nature Biotechnology, 24, 769–776.

Wu, C. Y., Yeh, Y. C., Yang, Y. C., Chou, C., Liu, M. T., Wu, H. S., et al. (2010). Mammalian expression of virus-like particles for advanced mimicry of authentic influenza virus. PLoS ONE, 5(3), e9784.

Mena, I., Vivo, A., Pérez, E., & Portela, A. (1996). Rescue of a synthetic chloramphenicol acetyltransferase RNA into influenza virus-like particles obtained from recombinant plasmids. Journal of Virology, 70, 5016–5024.

Akahata, W., Yang, Z. Y., Andersen, H., Sun, S., Holdaway, H. A., Kong, W. P., et al. (2010). A virus-like particle vaccine for epidemic Chikungunya virus protects nonhuman primates against infection. Nature Medicine, 16, 334–338.

Carlson, E. D., Gan, R., Hodgman, C. E. & Jewett, M. C. (2011). Cell-free protein synthesis: Applications come of age. Biotechnology Advances. doi:10.1016/j.biotechadv.2011.09.016.

Smith, M. T., Varner, C. T., Bush, D. B., & Bundy, B. C. (2012). The incorporation of the A2 protein to produce novel Qβ virus-like particles using cell-free protein synthesis. Biotechnology Progress, 28, 549–555.

Bundy, B. C., & Swartz, J. R. (2011). Efficient disulfide bond formation in virus-like particles. Journal of Biotechnology, 154, 230–239.

Patel, K. G., & Swartz, J. R. (2011). Surface functionalization of virus-like particles by direct conjugation using azide–alkyne click chemistry. Bioconjugate Chemistry, 22, 376–387.

Vicente, T., Mota, J. P., Peixoto, C., Alves, P. M., & Carrondo, M. J. (2011). Rational design and optimization of downstream processes of virus particles for biopharmaceutical applications: Current advances. Biotechnology Advances, 29, 869–878.

Cull, M., & McHenry, C. S. (1990). Preparation of extracts from prokaryotes. Methods in Enzymology, 182, 147–153.

Salazar, O., & Asenjo, J. A. (2007). Enzymatic lysis of microbial cells. Biotechnology Letters, 29, 985–994.

Hardy, E., Martínez, E., Diago, D., Díaz, R., González, D., & Herrera, L. (2000). Large-scale production of recombinant hepatitis B surface antigen from Pichia pastoris. Journal of Biotechnology, 77, 157–167.

Zhao, Q., Modis, Y., High, K., Towne, V., Meng, Y., Wang, Y., et al. (2012). Disassembly and reassembly of human papillomavirus virus-like particles produces more virion-like antibody reactivity. Virology Journal, 9, 52.

Lewis, G. D., & Metcalf, T. G. (1988). Polyethylene glycol precipitation for recovery of pathogenic viruses, including hepatitis A virus and human rotavirus, from oyster, water, and sediment samples. Applied and Environmental Microbiology, 54, 1983–1988.

Birnbaum, F., & Nassal, M. (1990). Hepatitis B virus nucleocapsid assembly: Primary structure requirements in the core protein. Journal of Virology, 64, 3319–3330.

Wróbel, B., Yosef, Y., Oppenheim, A. B., & Oppenheim, A. (2000). Production and purification of SV40 major capsid protein (VP1) in Escherichia coli strains deficient for the GroELS chaperone machine. Journal of Biotechnology, 84, 285–289.

White, L. J., Hardy, M. E., & Estes, M. K. (1997). Biochemical characterization of a smaller form of recombinant Norwalk virus capsids assembled in insect cells. Journal of Virology, 71, 8066–8072.

Branco, L. M., Grove, J. N., Geske, F. J., Boisen, M. L., Muncy, I. J., Magliato, S. A., et al. (2010). Lassa virus-like particles displaying all major immunological determinants as a vaccine candidate for Lassa hemorrhagic fever. Virology Journal, 7, 279.

Porterfield, J. Z., & Zlotnick, A. (2010). A simple and general method for determining the protein and nucleic acid content of viruses by UV absorbance. Virology, 407, 281–288.

Goodridge, L., Goodridge, C., Wu, J., Griffiths, M., & Pawliszyn, J. (2004). Isoelectric point determination of norovirus virus-like particles by capillary isoelectric focusing with whole column imaging detection. Analytical Chemistry, 76, 48–52.

Hewat, E. A., Booth, T. F., Loudon, P. T., & Roy, P. (1992). Three-dimensional reconstruction of baculovirus expressed bluetongue virus core-like particles by cryo-electron microscopy. Virology, 189, 10–20.

Fuller, S. D., Wilk, T., Gowen, B. E., Kräusslich, H. G., & Vogt, V. M. (1997). Cryo-electron microscopy reveals ordered domains in the immature HIV-1 particle. Current Biology, 7, 729–738.

Yu, X., Qiao, M., Atanasov, I., Hu, Z., Kato, T., Liang, T. J., et al. (2007). Cryo-electron microscopy and three-dimensional reconstructions of hepatitis C virus particles. Virology, 367, 126–134.

Voss, J. E., Vaney, M. C., Duquerroy, S., Vonrhein, C., Girard-Blanc, C., Crublet, E., et al. (2010). Glycoprotein organization of Chikungunya virus particles revealed by X-ray crystallography. Nature, 468, 709–712.

Kumar, S., Ochoa, W., Singh, P., Hsu, C., Schneemann, A., Manchester, M., et al. (2009). Tomato bushy stunt virus (TBSV), a versatile platform for polyvalent display of antigenic epitopes and vaccine design. Virology, 388, 185–190.

Crowther, R. A. (2010). From envelopes to atoms: The remarkable progress of biological electron microscopy. Advances in Protein Chemistry and Structural Biology, 81, 1–32.

Goldsmith, C. S., & Miller, S. E. (2009). Modern uses of electron microscopy for detection of viruses. Clinical Microbiology Reviews, 22, 552–563.

Persson, M., Tars, K., & Liljas, L. (2008). The capsid of the small RNA phage PRR1 is stabilized by metal ions. Journal of Molecular Biology, 383, 914–922.

Plevka, P., Kazaks, A., Voronkova, T., Kotelovica, S., Dishlers, A., Liljas, L., et al. (2009). The structure of bacteriophage phiCb5 reveals a role of the RNA genome and metal ions in particle stability and assembly. Journal of Molecular Biology, 391, 635–647.

Savithri, H. S., & Murthy, M. R. N. (2010). Structure and assembly of Sesbania mosaic virus. Current Science, 98, 346–351.

Lane, S. W., Dennis, C. A., Lane, C. L., Trinh, C. H., Rizkallah, P. J., Stockley, P. G., et al. (2011). Construction and crystal structure of recombinant STNV capsids. Journal of Molecular Biology, 413, 41–50.

Ausar, S. F., Foubert, T. R., Hudson, M. H., Vedvick, T. S., & Middaugh, C. R. (2006). Conformational stability and disassembly of Norwalk virus-like particles. Effect of pH and temperature. Journal of Biological Chemistry, 281, 19478–19488.

Cuellar, J. L., Meinhoevel, F., Hoehne, M., & Donath, E. (2010). Size and mechanical stability of norovirus capsids depend on pH: A nanoindentation study. Journal of General Virology, 91, 2449–2456.

Rumnieks, J., Ose, V., Tars, K., Dislers, A., Strods, A., Cielens, I., et al. (2009). Assembly of mixed rod-like and spherical particles from group I and II RNA bacteriophage coat proteins. Virology, 391, 187–194.

Lang, R., Winter, G., Vogt, L., Zurcher, A., Dorigo, B., & Schimmele, B. (2009). Rational design of a stable, freeze-dried virus-like particle-based vaccine formulation. Drug Development and Industrial Pharmacy, 35, 83–97.

Kissmann, J., Joshi, S. B., Haynes, J. R., Dokken, L., Richardson, C., & Middaugh, C. R. (2011). H1N1 influenza virus-like particles: Physical degradation pathways and identification of stabilizers. Journal of Pharmaceutical Sciences, 100, 634–645.

Bragard, C., Duncan, G. H., Wesley, S. V., Naidu, R. A., & Mayo, M. A. (2000). Virus-like particles assemble in plants and bacteria expressing the coat protein gene of Indian peanut clump virus. Journal of General Virology, 81, 267–272.

Lokesh, G. L., Gowri, T. D., Satheshkumar, P. S., Murthy, M. R., & Savithri, H. S. (2002). A molecular switch in the capsid protein controls the particle polymorphism in an icosahedral virus. Virology, 292, 211–223.

Hema, M., Subba Reddy, C. V., Savithri, H. S., & Sreenivasulu, P. (2008). Assembly of recombinant coat protein of sugarcane streak mosaic virus into potyvirus-like particles. Indian Journal of Experimental Biology, 46, 793–796.

Routh, A., Domitrovic, T., & Johnson, J. E. (2012). Host RNAs, including transposons, are encapsidated by a eukaryotic single-stranded RNA virus. Proceedings of the National Academy of Science of the United States of America, 109, 1907–1912.

Bunka, D. H., Lane, S. W., Lane, C. L., Dykeman, E. C., Ford, R. J., Barker, A. M., et al. (2011). Degenerate RNA packaging signals in the genome of Satellite Tobacco Necrosis Virus: Implications for the assembly of a T = 1 capsid. Journal of Molecular Biology, 413, 51–65.

Kaczmarczyk, S. J., Sitaraman, K., Young, H. A., Hughes, S. H., & Chatterjee, D. K. (2011). Protein delivery using engineered virus-like particles. Proceedings of the National Academy of Science of the United States of America, 108, 16998–17003.

Thomas, C. E., Ehrhardt, A., & Kay, M. A. (2003). Progress and problems with the use of viral vectors for gene therapy. Nature Reviews Genetics, 4, 346–358.

Storni, T., Ruedl, C., Schwarz, K., Schwendener, R. A., Renner, W. A., & Bachmann, M. F. (2004). Nonmethylated CG motifs packaged into virus-like particles induce protective cytotoxic T cell responses in the absence of systemic side effects. Journal of Immunology, 172, 1777–1785.

Ng, B. C., Chan, S. T., Lin, J., & Tolbert, S. H. (2011). Using polymer conformation to control architecture in semiconducting polymer/viral capsid assemblies. ACS Nano, 5, 7730–7738.

Newman, M., Chua, P. K., Tang, F. M., Su, P. Y., & Shih, C. (2009). Testing an electrostatic interaction hypothesis of hepatitis B virus capsid stability by using an in vitro capsid disassembly/reassembly system. Journal of Virology, 83, 10616–10626.

Fang, C. Y., Lin, P. Y., Ou, W. C., Chen, P. L., Shen, C. H., Chang, D., et al. (2012). Analysis of the size of DNA packaged by the human JC virus-like particle. Journal of Virological Methods, 182, 87–92.

Kaltgrad, E., O’Reilly, M. K., Liao, L., Han, S., Paulson, J. C., & Finn, M. G. (2008). On-virus construction of polyvalent glycan ligands for cell-surface receptors. Journal of the American Chemical Society, 130, 4578–4579.

Strable, E., & Finn, M. G. (2009). Chemical modification of viruses and virus-like particles. Current Topics in Microbiology and Immunology, 327, 1–21.

Spohn, G., Guler, R., Johansen, P., Keller, I., Jacobs, M., Beck, M., et al. (2007). A virus-like particle-based vaccine selectively targeting soluble TNF-alpha protects from arthritis without inducing reactivation of latent tuberculosis. Journal of Immunology, 178, 7450–7457.

Bachmann, M. F., & Jennings, G. T. (2011). Therapeutic vaccines for chronic diseases: Successes and technical challenges. Philosophical Transactions of the Royal Society B: Biological Sciences, 366, 2815–2822.

Spohn, G., Jennings, G. T., Martina, B. E., Keller, I., Beck, M., Pumpens, P., et al. (2010). A VLP-based vaccine targeting domain III of the West Nile virus E protein protects from lethal infection in mice. Virology Journal, 7, 146.

Pastori, C., Tudor, D., Diomede, L., Drillet, A. S., Jegerlehner, A., Röhn, T. A., et al. (2012). Virus like particle based strategy to elicit HIV-protective antibodies to the alpha-helic regions of gp41. Virology, 431, 1–11.

Smith, M. L., Lindbo, J. A., Dillard-Telm, S., Brosio, P. M., Lasnik, A. B., McCormick, A. A., et al. (2006). Modified Tobacco mosaic virus particles as scaffolds for display of protein antigens for vaccine applications. Virology, 348, 475–488.

Natilla, A., & Hammond, R. W. (2011). Maize rayado fino virus virus-like particles expressed in tobacco plants: A new platform for cysteine selective bioconjugation peptide display. Journal of Virological Methods, 178, 209–215.

Minten, I. J., Claessen, V. I., Blank, K., Rowan, A. E., Nolte, R. J. M., & Cornelissen, J. J. (2011). Catalytic capsids: The art of confinement. Chemical Science, 2, 358–362.

Minten, I. J., Hendriks, L. J., Nolte, R. J., & Cornelissen, J. J. (2009). Controlled encapsulation of multiple proteins in virus capsids. Journal of the American Chemical Society, 131, 17771–17773.

Ohtake, N., Niikura, K., Suzuki, T., Nagakawa, K., Mikuni, S., Matsuo, Y., et al. (2010). Low pH-triggered model drug molecule release from virus-like particles. ChemBioChem, 11, 959–962.

Walker, A., Skamel, C., & Nassal, M. (2011). SplitCore: An exceptionally versatile viral nanoparticle for native whole protein display regardless of 3D structure. Scientific Reports, 1, 5.

Werner, S., Marillonnet, S., Hause, G., Klimyuk, V., & Gleba, Y. (2006). Immunoabsorbent nanoparticles based on a tobamovirus displaying protein A. Proceedings of the National Academy of Science of the United States of America, 103, 17678–17683.

Gleiter, S., & Lilie, H. (2005). Cell-type specific targeting and gene expression using a variant of polyoma VP1 virus-like particles. Biological Chemistry, 384, 247–255.

Park, J. S., Cho, M. K., Lee, E. J., Ahn, K. Y., Lee, K. E., Jung, J. H., et al. (2009). A highly sensitive and selective diagnostic assay based on virus nanoparticles. Nature Nanotechnology, 4, 259–264.

Cardinale, D., Carette, N., & Michon, T. (2012). Virus scaffolds as enzyme nano-carriers. Trends in Biotechnology, 30, 369–376.

Mokili, J. L., Rohwer, F., & Dutilh, B. E. (2012). Metagenomics and future perspectives in virus discovery. Current Opinion in Virology, 2, 63–77.

Janssens, M. E., Geysen, D., Broos, K., De Goeyse, I., Robbens, J., Van Petegem, F., et al. (2010). Folding properties of the hepatitis B core as a carrier protein for vaccination research. Amino Acids, 38, 1617–1626.

Hulo, C., de Castro, E., Masson, P., Bougueleret, L., Bairoch, A., Xenarios, I., et al. (2011). ViralZone: A knowledge resource to understand virus diversity. Nucleic Acids Research, 39, D576–D582.

Tremblay, M. H., Majeau, N., Gagné, M. E., Lecours, K., Morin, H., Duvignaud, J. B., et al. (2006). Effect of mutations K97A and E128A on RNA binding and self assembly of papaya mosaic potexvirus coat protein. FEBS Journal, 273, 14–25.

Caballero, S., Guix, S., Ribes, E., Bosch, A., & Pintó, R. M. (2004). Structural requirements of astrovirus virus-like particles assembled in insect cells. Journal of Virology, 78, 13285–13292.

Farnós, O., Fernández, E., Chiong, M., Parra, F., Joglar, M., Méndez, L., et al. (2009). Biochemical and structural characterization of RHDV capsid protein variants produced in Pichia pastoris: Advantages for immunization strategies and vaccine implementation. Antiviral Research, 81, 25–36.

Lu, X. Y., Chen, Y., Bai, B. K., Hu, H., Tao, L., Yang, J., et al. (2007). Immune responses against SARS CoV induced by virus-like particles in mice. Immunology, 122, 496–502.

Ohtaki, N., Takahashi, H., Kaneko, K., Gomi, Y., Ishikawa, T., Higashi, Y., et al. (2010). Immunogenicity and efficacy of two types of West Nile virus-like particles different in size and maturation as a second-generation vaccine candidate. Vaccine, 28, 6588–6596.

Li, T. C., Yamakawa, Y., Suzuki, K., Tatsumi, M., Razak, M. A., Uchida, T., et al. (1997). Expression and self-assembly of empty virus-like particles of hepatitis E virus. Journal of Virology, 71, 7207–7213.

Cielens, I., Ose, V., Petrovskis, I., Strelnikova, A., Renhofa, R., Kozlovska, T., et al. (2000). Mutilation of RNA phage Qbeta virus-like particles: From icosahedrons to rods. FEBS Letters, 482, 261–264.

Lamb, J. W., Duncan, G. H., Reavy, B., Gildow, F. E., Mayo, M. A., & Hay, R. T. (1996). Assembly of virus-like particles in insect cells infected with a baculovirus containing a modified coat protein gene of potato leafroll luteovirus. Journal of General Virology, 77, 1349–1358.

Schneemann, A., Dasgupta, R., Johnson, J. E., & Rueckert, R. R. (1993). Use of recombinant baculoviruses in synthesis of morphologically distinct viruslike particles of flock house virus, a nodavirus. Journal of Virology, 67, 2756–2763.

Luo, L., Li, Y., & Kang, C. Y. (1990). Expression of gag precursor protein and secretion of virus-like gag particles of HIV-2 from recombinant baculovirus-infected insect cells. Virology, 179, 874–880.

Shanks, M., & Lomonossoff, G. P. (2000). Co-expression of the capsid proteins of Cowpea mosaic virus in insect cells leads to the formation of virus-like particles. Journal of General Virology, 81, 3093–3097.

Pringle, F. M., Kalmakoff, J., & Ward, V. K. (2001). Analysis of the capsid processing strategy of Thosea asigna virus using baculovirus expression of virus-like particles. Journal of General Virology, 82, 259–266.

Sastri, M., Kekuuda, R., Gopinath, K., Ranjith Kumar, C. T., Jagath, J. R., & Savithri, H. S. (1997). Assembly of physalis mottle virus capsid protein in Escherichia coli and the role of amino and carboxy termini in the formation of the icosahedral particles. Journal of Molecular Biology, 272, 541–552.

Li, C., Liu, F., Liang, M., Zhang, Q., Wang, X., Wang, T., et al. (2010). Hantavirus-like particles generated in CHO cells induce specific immune responses in C57BL/6 mice. Vaccine, 28, 4294–4300.

Warfield, K. L., Bosio, C. M., Welcher, B. C., Deal, E. M., Mohamadzadeh, M., Schmaljohn, A., et al. (2003). Ebola virus-like particles protect from lethal Ebola virus infection. Proceedings of the National Academy of Science of the United States of America, 100, 15889–15894.

Walpita, P., Barr, J., Sherman, M., Basler, C. F., & Wang, L. (2011). Vaccine potential of Nipah virus-like particles. PLoS ONE, 6(4), e18437.

Fernández-Arias, A., Risco, C., Martínez, S., Albar, J. P., & Rodríguez, J. F. (1998). Expression of ORF A1 of infectious bursal disease virus results in the formation of virus-like particles. Journal of General Virology, 79, 1047–1054.

Fender, P., Ruigrok, R. W., Gout, E., Buffet, S., & Chroboczek, J. (1997). Adenovirus dodecahedron, a new vector for human gene transfer. Nature Biotechnology, 15, 52–56.

Yin, S., Sun, S., Yang, S., Shang, Y., Cai, X., & Liu, X. (2010). Self-assembly of virus-like particles of porcine circovirus type 2 capsid protein expressed from Escherichia coli. Virology Journal, 7, 166.

Newcomb, W. W., Homa, F. L., Thomsen, D. R., Trus, B. L., Cheng, N., Steven, A., et al. (1999). Assembly of the herpes simplex virus procapsid from purified components and identification of small complexes containing the major capsid and scaffolding proteins. Journal of Virology, 73, 4239–4250.

Saliki, J. T., Mizak, B., Flore, H. P., Gettig, R. R., Burand, J. P., Carmichael, L. E., et al. (1992). Canine parvovirus empty capsids produced by expression in a baculovirus vector: Use in analysis of viral properties and immunization of dogs. Journal of General Virology, 73, 369–374.

Sasnauskas, K., Bulavaite, A., Hale, A., Jin, L., Knowles, W. A., Gedvilaite, A., et al. (2002). Generation of recombinant virus-like particles of human and non-human polyomaviruses in yeast Saccharomyces cerevisiae. Intervirology, 45, 308–317.

Acknowledgments

I wish to thank Prof. Dr. P. Pumpens for support during the preparation and critical reading the manuscript, Dr. K. Tars, and Dr. A. Kazaks for helpful discussions. I apologize to the authors for the important work not cited in this review. The writing of the review was supported by the ERAF grant 2010/0314/2DP/2.1.1.1.0/10/APIA/VIAA/052.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material