Abstract

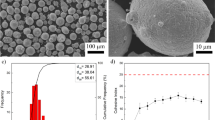

In this work, a set of experiments was designed to investigate the effect of process parameters on the relative density of the AlSi10Mg parts manufactured by SLM. The influence of laser scan speed v, laser power P and hatch space H, which were considered as the dominant parameters, on the powder melting and densification behavior was also studied experimentally. In addition, the laser energy density was introduced to evaluate the combined effect of the above dominant parameters, so as to control the SLM process integrally. As a result, a high relative density (> 97%) was obtained by SLM at an optimized laser energy density of 3.5-5.5 J/mm2. Moreover, a parameter–densification map was established to visually select the optimum process parameters for the SLM-processed AlSi10Mg parts with elevated density and required mechanical properties. The results provide an important experimental guidance for obtaining AlSi10Mg components with full density and gradient functional porosity by SLM.

Similar content being viewed by others

References

J.P. Kruth, L. Froyen, J. Van Vaerenbergh et al., Selective Laser Melting of Iron-Based Powder, J. Mater. Process. Technol., 2004, 149(1), p 616–622

F. Calignano, D. Manfredi, E.P. Ambrosio et al., Direct Fabrication of Joints Based on Direct Metal Laser Sintering in Aluminum and Titanium Alloys, Proc. CIRP, 2014, 21, p 129–132

P. Yuan, D. Gu, and D. Dai, Particulate Migration Behavior and Its Mechanism During Selective Laser Melting of TiC Reinforced Al Matrix Nanocomposites, Mater. Des., 2015, 82, p 46–55

S.L. Sing, L.P. Lam, D.Q. Zhang et al., Interfacial Characterization of SLM Parts in Multi-Material Processing: Intermetallic Phase Formation Between AlSi10Mg and C18400 Copper Alloy, Mater. Charact., 2015, 107, p 220–227

E. Louvis, P. Fox, and C.J. Sutcliffe, Selective Laser Melting of Aluminium Components, J. Mater. Process. Technol., 2011, 211(2), p 275–284

E.O. Olakanmi, R.F. Cochrane, and K.W. Dalgarno, A Review on Selective Laser Sintering/melting (SLS/SLM) of Aluminium Alloy Powders: Processing, Microstructure, and Properties, Prog. Mater. Sci., 2015, 74, p 401–477

Y. Li and D. Gu, Parametric Analysis of Thermal Behavior During Selective Laser Melting Additive Manufacturing of Aluminum Alloy Powder, Mater. Des., 2014, 63, p 856–867

K. Kempen, L. Thijs, J. Van Humbeeck et al., Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting, Phys. Proc., 2012, 39, p 439–446

K. Kempen, L. Thijs, E. Yasa, et al., Process Optimization and microstructural analysis for selective laser melting of AlSi10Mg, in Proceedings of the Solid Freeform Fabrication Symposium, vol. 22 (2011), p. 484–495

C. Weingarten, D. Buchbinder, N. Pirch et al., Formation and Reduction of Hydrogen Porosity During Selective Laser Melting of AlSi10Mg, J. Mater. Process. Technol., 2015, 221, p 112–120

L. Thijs, K. Kempen, J.P. Kruth et al., Fine-structured Aluminium Products With Controllable Texture by Selective Laser Melting of Pre-alloyed AlSi10Mg Powder, Acta Mater., 2013, 61(5), p 1809–1819

N. Read, W. Wang, K. Essa et al., Selective Laser Melting of AlSi10Mg Alloy: Process Optimisation and Mechanical Properties Development, Mater. Des., 2015, 65, p 417–424

J.P. Kruth, P. Mercelis, J. Van Vaerenbergh et al., Binding Mechanisms in Selective Laser Sintering and Selective Laser Melting, Rapid Prototype J., 2005, 11(1), p 26–36

K. Kempen, B. Vrancken, S. Buls et al., Selective Laser Melting of Crack-Free High Density M2 High Speed Steel Parts by Baseplate Preheating, J. Manuf. Sci. Eng., 2014, 136(6), p 061026

M. Godino Martinez, PFC: AlSi10Mg Parts Produced by Selective Laser Melting (SLM), KU LEUVEN-Universidad Carlos III de Madrid, Madrid, 2013

R.H. Morgan, A.J. Papworth, C. Sutcliffe et al., High Density Net Shape Components by Direct Laser Re-Melting of Single-Phase Powders, J. Mater. Sci., 2002, 37(15), p 3093–3100

Acknowledgments

The research is financially supported by Science Challenge Project of China and Dongguan University of Technology high-level talents (innovation team) research project (Project No. KCYCXPT2016003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Wei, Z., Wei, P. et al. Experimental Research on Selective Laser Melting AlSi10Mg Alloys: Process, Densification and Performance. J. of Materi Eng and Perform 26, 5897–5905 (2017). https://doi.org/10.1007/s11665-017-3044-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3044-5