Abstract

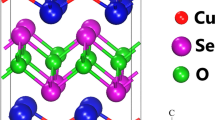

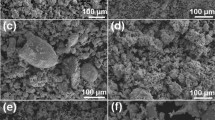

BiCuSeO is regarded as one of the most promising oxygenated thermoelectric materials because of its special natural superlattice structure and corresponding ultra-low thermal conductivity. In order to improve the thermoelectric performance, we should pay attention to both composition adjustment and structure adjustment. In this paper, we report a study which combines the two ways to improve the electrical transporting performance and suppress the thermal transporting performance, and we have effectively improved the thermoelectric performance. Firstly, by adjusting the composition with In doping at the Bi site, the band gap widens, the energy offset between heavy band and light band increases, and the mobility and electrical transporting performance improves correspondingly. The maximum ZT value is increased to 0.61. Based on this, the thermoelectric properties are further improved in the whole temperature range by increasing the mechanical alloying strength to refine the powders and adjusting the proportion of fine powder and coarse powder. Grain refinement increases the Cu vacancies and corresponding electrical properties. In addition, Grain refinement contributes to enhancing phonon scattering and effectively reduces the lattice thermal conductivity. The thermal conductivity decreases significantly in the whole temperature range because grain refinement can significantly enhance phonon scattering and reduce the lattice thermal conductivity. The appropriate proportion of coarse powder and fine powder can make full use of the fine grains to enhance phonon scattering while enlarging the frequency range of scattered phonons, thus further reducing the thermal conductivity. Finally, the ZT value increased to 1.08.

Similar content being viewed by others

References

Y.K. Lee, K. Ahn, J. Cha, C. Zhou, H.S. Kim, G. Choi, and Y.E. Sung, J. Am. Chem. Soc. 139, 10887 (2017).

F.J. DiSalvo, Science 285, 703–706 (1999).

G. Snyder and E.S. Toberer, Nat. Mater. 7, 105 (2008).

L.D. Zhao, J. He, D. Berardan, Y. Lin, J.F. Li, C.W. Nan, and N. Dragoe, Energy Environ. Sci. 7, 2923 (2014).

J. Li, J. Sui, Y. Pei, C. Barreteau, D. Berardan, N. Dragoe, and L.D. Zhao, Energy Environ. Sci. 5, 8544 (2012).

L. Pan, D. Bérardan, L. Zhao, C. Barreteau, and N. Dragoe, Appl. Phys. Lett. 102, 023902 (2013).

J. Li, J. Sui, Y.L. Pei, X. Meng, D. Berardan, N. Dragoe, W. Cai, and L.D. Zhao, J. Mater. Chem. A 2, 4904 (2014).

B. Feng, G. Li, Y. Hou, C. Zhang, C. Jiang, J. Hu, Q. Xiang, Y. Li, Z. He, and X. Fan, J. Alloys Compd. 712, 391 (2017).

J.D. Lei, W.B. Guan, D. Zhang, Z. Ma, X.Y. Yang, C. Wang, and Y.X. Wang, Appl. Surf. Sci. 473, 988 (2019).

Y. Liu, L.D. Zhao, Y. Liu, J. Lan, W. Xu, F. Li, B.P. Zhang, D. Berardan, N. Dragoe, Y.H. Lin, C.W. Nan, and J.F. Li, J. Am. Chem. Soc. 133, 20112 (2011).

Z. Li, C. Xiao, S. Fan, Y. Deng, W. Zhang, and B. Ye, J. Am. Chem. Soc. 137, 6587 (2015).

J. Sui, J. Li, J. He, Y.L. Pei, D. Berardan, H. Wu, N. Dragoe, W. Cai, and L.D. Zhao, Energy Environ. Sci. 6, 2918 (2013).

Z. Dashevsky, S. Shusterman, M.P. Dariel, and I. Drabkin, J. Appl. Phys. 92, 1425 (2002).

A. Bali, H. Wang, G.J. Snyder, and R.C. Mallik, J. Appl. Phys. 116, 033707 (2014).

Q. Zhang, B.L. Liao, Y.C. Lan, K. Lukas, W.S. Liu, K. Esfarjani, D. Broido, C. Opeil, G. Chen, and Z.F. Ren, Proc. Natl. Acad. Sci. 110, 13262 (2013).

X.A. Fan, X. Cai, Z. Rong, F. Yang, G. Li, and Z. Gan, J. Alloys Compd. 607, 91 (2014).

B. Feng, G. Li, Y. Hou, C. Zhang, C. Jiang, J. Hu, Q. Xiang, Y. Li, Z. He, and X. Fan, J. Alloys Compd. 754, 135 (2018).

A. Hmood, A. Kadhim, and H.A. Hassan, J. Alloys Compd. 520, 2 (2012).

H. Wang, Z.M. Gibbs, Y. Takagiwa, and G.J. Snyder, Energy Environ. Sci. 7, 804 (2014).

Y. Pei, N.A. Heinz, A. LaLonde, and G.J. Snyder, Energy Environ. Sci. 4, 3640 (2011).

C.M. Jaworski, M.D. Nielsen, H. Wang, S.N. Girard, W. Cai, W.D. Porter, and J.P. Heremans, Phys. Rev. B 87, 045203 (2013).

Y. Liu, J. Ding, B. Xu, J. Lan, Y. Zheng, B. Zhan, and C. Nan, Appl. Phys. Lett. 106, 233903 (2015).

Y. Yang, X. Liu, and X. Liang, Dalton Trans. 46, 2510 (2017).

F. Li, J.F. Li, L.D. Zhao, K. Xiang, Y. Liu, B.P. Zhang, Y.H. Lin, C.W. Nan, and H.M. Zhu, Energy Environ. Sci. 5, 7188 (2012).

H. Lin, H. Chen, N. Ma, Y.J. Zheng, J.N. Shen, J.S. Yu, and L.M. Wu, Inorg. Chem. Front. 4, 1273 (2017).

B. Paul and P. Banerji, J. Appl. Phys. 108, 064322 (2010).

B. Feng, G. Li, Z. Pan, C. Zhang, C. Jiang, J. Hu, Q. Xiang, Y. Li, Z. He, and X. Fan, J. Solid State Chem. 265, 306 (2018).

S.I. Kim, K.H. Lee, H.A. Mun, H.S. Kim, S.W. Hwang, J.W. Roh, and G.J. Snyder, Science 348, 109 (2015).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51674181), Key Project of Department of Education of Hubei Provincial (D20151103), and National Defense Pre-research Foundation of Wuhan University of Science and Technology (GF201707).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Feng, B., Li, G., Hu, X. et al. Enhancement of the Thermoelectric Properties of BiCuSeO via In Doping and Powder Size Controlling. J. Electron. Mater. 49, 611–620 (2020). https://doi.org/10.1007/s11664-019-07720-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-07720-7