Abstract

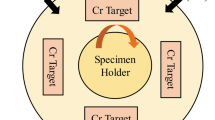

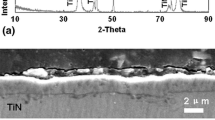

Three CrN coatings were deposited on the Inconel X750 through the metal vapor vacuum arc ion implantation and the magnetic filtered cathodic vacuum arc deposition system (MEVVA-FCVA) with the N2 flow rates of 10, 50, and 100 sccm, respectively. The surface morphologies and cross-section morphologies of the CrN coatings were obtained through scanning electron microscopy (SEM) and an optical profilometer. The microstructures of the coatings were characterized through X-ray diffraction (XRD). The hardness and the elastic modulus of the coatings were tested by a nano-hardness tester. The adhesion strength and friction coefficients were investigated through scratch tests and ball-on-disk tests and the wear tracks were tested by the optical profilometer. The experimental results indicate that the CrN coating deposited on the Inconel X750 substrate displays a uniform thickness and a smooth surface. The mechanical properties behaves well as the N2 flow rate varies. The CrN coating significantly reduces the friction coefficient fluctuation and improves the antiadhesion and anti-wear properties of the Inconel X750.

Similar content being viewed by others

References

Altin O, Eser S. Pre-oxidation of Inconel Alloys for Inhibition of Carbon Deposition from Heated Jet Fuel [J]. Oxidation of Metals, 2006, 65(1/2): 75–99

Dellacorte C, Zaldana AR, Radil KC. A Systems Approach to the Solid Lubrication of Foil Air Bearings for Oil-free Turbomachinery [J]. Journal of Tribology, 2004, 126: 200–207

Heshmat H, Hryniewicz P, Walton II JF, et al. Low-friction Wearresistant Coatings for High-temperature Foil Bearings [J]. Tribology International, 2005, 38 (11/12): 1059–1075

Fanning CE, Blanchet TA. High-temperature Evaluation of Solid Lubricant Coatings in a Foil Thrust Bearing [J]. Wear, 2008, 265 (7/8): 1076–1086

Qureshi IN, Shahid M, Nusair KA. Hot Corrosion of Yttria-stabilized Zirconia Coating, in a Mixture of Sodium Sulfate and Vanadium Oxide at 950? [J]. Journal of Thermal Spray Technology, 2016, 25(3): 567–579

Judge CD, Gauquelin N, Walters L, et al. Intergranular Fracture in Irradiated Inconel X-750Containing Very High Concentrations of Helium and Hydrogen [J]. Journal of Nuclear Materials, 2015, 457: 165–172

Polcar T, Parreira NMG, Novák R. Friction and Wear Behaviour of CrN Coating at Temperatures up to 500? [J]. Surface and Coatings Technology, 2007, 201(9/10/11): 5228–5235

Polcar T, Martinez R, Vítu T, et al. High Temperature Tribology of CrN and Multilayered Cr/CrN Coatings [J]. Surface and Coatings Technology, 2009, 203(20/21): 3254–3259

Wang L, Nie X. Effect of Annealing Temperature on Tribological Properties and Material Transfer Phenomena of CrN and CrAlN Coatings [J]. Journal of Materials Engineering and Performance, 2014, 23(2): 560–571

Shan L, Zhang Y, Wang Y, et al. Corrosion and Wear Behaviors of PVD CrN and CrSiN Coatings in Seawater [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 175–184

Ruden A, Restrepo PE, Paladines AU, et al. Corrosion Resistance of CrN Thin Films Produced by dc Magnetron Sputtering [J]. Applied Surface Science, 2013, 270: 150–156

Gilewicz A, Chmielewska P, Murzynski D, et al. Corrosion Resistance of CrN and CrCN/CrN Coatings Deposited Using Cathodic Arc Evaporation in Ringer’s and Hank’s Solutions [J]. Surface and Coatings Technology, 2016, 299: 7–14

Chen Q, Cao Y, Xie Z, et al. Tribocorrosion Behaviors of CrN Coating in 3.5wt% NaCl Solution [J]. Thin Solid Films, 2017, 622: 41–47

Basu A, Dutta Majumdar J, Manna I. Structure and Properties of CrxN Coating [J]. Surface Engineering, 2012, 28(3): 199–204

Shen LH, Cui QL. Synthesis of Cubic Chromium Nitride Nanocrystals Powders by Arc Discharge Plasma Method [J]. Journal of Inorganic Materials, 2010, 25(4): 411–414

Wang Q, Zhou F, WANG X, et al. Comparison of Tribological Properties of CrN, TiCN and TiAlN Coatings Sliding Against SiC Balls in Water [J]. Applied Surface Science, 2011, 257(17): 7813–7820

Su Y L, Yao S H, Leu Z L, et al. Comparison of Tribological Behavior of Three Films-TiN, TiCN and CrN-grown by Physical Vapor Deposition [J]. Wear, 1997, 213(1): 165–174

Podgornik B, Sedlacek M, Mandrino D. Performance of CrN Coatings under Boundary Lubrication [J]. Tribology International, 2016, 96: 247–257

Bandeira A L, Trentin R, Aguzzoli C, et al. Sliding Wear and Friction Behavior of CrN-coating in Ethanol and Oil-ethanol Mixture [J]. Wear, 2013, 301(1/2): 786–794

Zhou F, Chen K, Wang M, et al. Friction and Wear Properties of CrN Coatings Sliding Against Si3N4 Balls in Water and Air [J]. Wear, 2008, 265(7/8): 1029–1037

Aissani L, Nouveau C, Walock M J, et al. Influence of Vanadium on Structure, Mechanical and Tribological Properties of CrN Coatings [J]. Surface Engineering, 2015, 31(10): 779–788

Laxane R B, Bhide R S, Patil A S, et al. Characterisation of Chromium Nitride Physical Vapour Deposition Coating on Diesel Engine Pistons [J]. Surface Engineering, 2006, 22(1): 78–80

Etsion I, Halperin G, Becker E. The Effect of Various Surface Treatments on Piston Pin Scuffing Resistance [J]. Wear, 2006, 261(7/8): 785–791

Obrosov A, Sutygina A, Volinsky A, et al. Effect of Hydrogen Exposure on Mechanical and Tribological Behavior of CrxN Coatings Deposited at Different Pressures on IN718 [J]. Materials, 2017, 10(563): 1–11

Wan S, Pu J, Li D, et al. Tribological Performance of CrN and CrN/ GLC Coated Components for Automotive Engine Applications [J]. Journal of Alloys and Compounds, 2017, 695: 433–442

Jin J, Duan H, Li X. The Influence of Plasma Nitriding on Microstructure and Properties of CrN and CrNiN Coatings on Ti6Al4V by Magnetron Sputtering [J]. Vacuum, 2017, 136: 112–120

[27] Forniés E, Escobar Galindo R, Sánchez O, et al. Growth of CrNx Films by DC Reactive Magnetron Sputtering at Constant N2/Ar Gas Flow [J]. Surface and Coatings Technology, 2006, 200(20/21): 6047–6053

Warcholinski B, Gilewicz A, Kuklinski Z, et al. Arc-evaporated CrN, CrN and CrCN Coatings [J]. Vacuum, 2008, 83(4): 715–718

Zhou F, Wang Y, Liu F, et al. Friction and Wear Properties of Duplex MAO/CrN Coatings Sliding Against Si3N4 Ceramic Balls in Air, Water and Oil [J]. Wear, 2009, 267(9/10): 1581–1588

Cai F, Huang X, Yang Q, et al. Microstructure and Tribological Properties of CrN and CrSiCN Coatings [J]. Surface and Coatings Technology, 2010, 205(1): 182–188

Subramanian B, Prabakaran K, Jayachandran M. Influence of Nitrogen flow Rates on Materials Properties of CrN(x) Films [J]. Bulletin of Materials Science, 2012, 35: 505–511

Cecchini R, Fabrizi A, Cabibbo M, et al. Mechanical, Microstructural and Oxidation Properties of Reactively Sputtered Thin CrN Coatings on Steel [J]. Thin Solid Films, 2011, 519(19): 6515–6521

Khojier K, Savaloni H, Zolghadr S, et al. Study of Electrical, Mechanical, and Tribological Properties of CrNx Thin Films as a Function of Sputtering Conditions [J]. Journal of Materials Engineering and Performance, 2014, 23(10): 3444–3448

Zhu SF, Wu YP, Liu TW, et al. Effect of N2 Flow on Microstructure and Properties of CrNx Film Prepared by Unbalanced Magnetron Sputtering on the Surface of Depleted Uranium [J]. Journal of Inorganic Materials, 2012, 27(6): 603–608

Bouzakis KD, Vidakis N, Leyendecker T, et al. Determination of the Fatigue Behaviour of Thin Hard Coatings Using the Impact Test and a FEM Simulation [J]. Surface and Coatings Technology, 1996, 86): 549–556

Paouris LI, Bompos DA, Nikolakopoulos P G. Simulation of Static Performance of Air Foil Bearings Using Coupled Finite Element and Computational Fluid Dynamics Techniques [J]. Journal of Engineering for Gas Turbines and Power, 2014, 136: 022503-1-11

Broitman E. Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale): A Critical Overview [J]. Tribology Letters, 2017, 65 (1): 1–18

Wang QZ, Zhou F, Yan JW. Evaluating Mechanical Properties and Crack Resistance of CrN, CrTiN, CrAlN and CrTiAlN Coatings by Nanoindentation and Scratch Tests [J]. Surface and Coatings Technology, 2016, 285: 203–213

Elangovan T, Kuppusami P, Thirumurugesan R, et al. Nanostructured CrN Thin Films Prepared by Reactive Pulsed DC Magnetron Sputtering [J]. Materials Science and Engineering): B, 2010, 167(1): 17–25

Wiecinski P, Smolik J, Garbacz H, et al. Microstructure and Mechanical Properties of Nanostructure Multilayer CrN/Cr Coatings on Titanium Alloy [J]. Thin Solid Films, 2011, 519(12): 4069–4073

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Special Plan of Scientific and Technological Innovation for Graduate Student in Beijing Institute of Technology (2015CX10015), and the National Natural Science Foundation of China (51405455)

Rights and permissions

About this article

Cite this article

Liu, J., Liao, R., Liao, B. et al. Mechanical and Tribological Properties of CrN Coated Inconel X750. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 804–810 (2019). https://doi.org/10.1007/s11595-019-2121-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-019-2121-z