Abstract

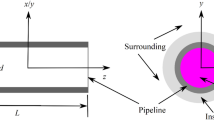

The 2010/31/CE directive has highlighted the necessity to improve the energy efficiency in buildings, since they are responsible for 40% of energy consumption and 36% of CO2 emissions in the EU. In situ measurements of envelope components are needed for estimating the thermal transmittance of existing buildings in order to perform the energy certification. The instruments devoted to this aim, the heat flux meters (HFMs), are unfortunately not always provided with metrological traceability, and the appropriate reference standards are not available. The calibration systems currently adopted present different limits related to low performances at low and constant heat fluxes, non-uniformity of the heat flux in the measurement section and impossibility to control the heat flux at different temperatures. In this paper, the authors discuss the metrological behaviour of an existing HFM reference standard. A numerical model is employed to analyse the calibration system in different operating conditions (low and moderate heat fluxes), to improve it and to design a new prototype presenting high performances also in the presence of the HFM under calibration. In particular, the numerical tool is applied to investigate the heat flux uniformity and the metrological performances in a specific sub-region of the measuring section where the HFM under calibration is applied. A detailed experimental analysis is also conducted with the objective to validate the adopted numerical tool. Moreover, a metrological characterization of the system affords a combined standard uncertainty of better than 6% at low heat flows.

Similar content being viewed by others

References

Buildings. In: Policies, information and services. European Commission. 2018. https://ec.europa.eu/energy/en/topics/energy-efficiency/buildings. Accessed 11 Feb 2019.

Arpino F, Cortellessa G, Dell’Isola M, Ficco G, Marchesi R, Tarini C. Influence of installation conditions on heating bodies thermal output: preliminary experimental results. Energy Procedia. 2016;101:74–80.

Lakatos Á. Thermal conductivity of insulations approached from a new aspect. J Therm Anal Calorim. 2018;133(1):329–35.

Audoit J, Rivière L, Dandurand J, Lonjon A, Dantras E, Lacabanne C. Thermal, mechanical and dielectric behaviour of poly(aryl ether ketone) with low melting temperature. J Therm Anal Calorim. 2018;135:1–11.

ISO 9869-1:2014, Thermal insulation—building elements—In-situ measurement of thermal resistance and thermal transmittance—Part 1: Heat flow meter method. ISO; 2014.

Ai Q, Hu ZW, Liu M, Xia XL, Xie M. Influence of sensor orientations on the thermal conductivity measurements of liquids by transient hot disk technique. J Therm Anal Calorim. 2017;128(1):289–300.

ASTM C1130: Standard practice for calibration of thin heat flux transducers. West Conshohocken: ASTM International; 2017.

ASTM C177-13: Standard test method for steady-state heat flux measurements and thermal transmission properties by means of the guarded-hot-plate apparatus. West Conshohocken: ASTM International; 2013.

ISO 8302: Thermal insulation—determination of steady-state thermal resistance and related properties—guarded hot plate apparatus. ISO; 1991.

ASTM C518-17: Standard test method for steady-state thermal transmission properties by means of the heat flow meter apparatus. West Conshohocken: ASTM International; 2017.

ISO 8301: Thermal insulation—determination of steady-state thermal resistance and related properties—heat flow meter apparatus. ISO; 1991.

Guattari C, Evangelisti L, Gori P, Asdrubali F. Influence of internal heat sources on thermal resistance evaluation through the heat flow meter method. Energy Build. 2017;135:187–200.

Van der Graaf F. Heat flux sensors. New York: Sensors; 1989.

Flanders SN. Heat flux transducers measure in situ building thermal performance. J Therm Insul Build Environ. 1994;18:28–52.

Hauser RL. Construction and performance of in situ heat flux transducers. In: Bales E, Bomberg M, Courville GE, editors. Building applications of heat flux transducers, ASTM STP 885. Philadelphia: American Society for Testing and Materials; 1985. pp. 172–83.

Murthy AV. Radiative calibration of heat-flux sensors at NIST: facilities and techniques. J Res NIST. 2000;105(2):293–305.

Lackey J, Normandin N, Marchand R, Kumaran K. Calibration of heat flow meter apparatus. J Therm Insul Build Environ. 1994;18:128–44.

Bomberg M, Solvason KR. Comments on calibration and design of heat flow meter. In: Thermal insulation, materials and systems for energy conservation in the ‘80 s ASTM, STP 789. Canada: National Research Council (NRC) Publications Archive (NPArC), Division of Building Research (DBR); 1983, pp. 277–92. http://web.mit.edu/parmstr/Public/NRCan/nrcc22416.pdf. Accessed 02 May 2019.

Dubois S, Lebeau F. Design, construction and validation of a guarded hot plate apparatus for thermal conductivity measurement of high thickness crop-based specimens. Mater Struct. 2013;48(1–2):407–21.

Reid D. Guarded hot plate apparatus design and construction for thermal conductivity measurements. Toronto: Ryerson University; 2005.

Tleoubaev A, Brzezinski A. Combined guarded-hot-plate and heat flow meter method for absolute thermal conductivity tests excluding thermal contact resistance. Thermal Conductivity 27/Thermal Expansion 15; Knoxville (Tennessee), 2003.

Reddy KS, Jayachandran S. Investigations on design and construction of a square guarded hot plate (SGHP) apparatus for thermal conductivity measurement of insulation materials. Int J Therm Sci. 2017;120:136–47.

Le Quang H, Pham DC, Bonnet G. Size effect in through-thickness conductivity of heterogeneous plates. Int J Therm Sci. 2014;79:40–50.

Liu CL, Gao C, von Wolfersdorf J, Zhai YN. Numerical study on the temporal variations and physics of heat transfer coefficient on a flat plate with unsteady thermal boundary conditions. Int J Therm Sci. 2017;113:20–37.

Arpino F, Dell’Isola M, Ficco G, Iacomini L, Fernicola V. Design of a calibration system for heat flux meters. Int J Thermophys. 2011;32(11–12):2727–34.

Fave L, Pouchon MA, Hébert C. A radial heat flow apparatus for thermal conductivity characterisation of cylindrical samples. J Therm Anal Calorim. 2017;130(3):1855–63.

Bomberg M, Solvason KR. Discussion of heat flow meter apparatus and transfer standards used for error analysis. In: Shirtliffe J, Tye RP, editors. Guarded hot plate and heat flow meter methodology. Philadelphia: American Society for Testing and Materials; 1985. p. 140–53.

UNI CEI 70098-3: Incertezza di misura—Parte 3: Guida all’espressione dell’incertezza di misura. UNI; 2016.

JCGM. Evaluation of measurement data—the role of measurement uncertainty in conformity assessment. Joint Committee for Guides in Metrology; 2012.

Jacobs T. Experimental and uncertainty analysis for engineers. J Test Eval. 1991;19(6):498–9. https://doi.org/10.1520/JTE12616J.

Betta G, Dell’Isola M, Frattolillo A. Experimental design techniques for optimising measurement chain calibration. Measur J Int Meas Confed. 2001;30(2):115–27.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cortellessa, G., Arpino, F., Dell’Isola, M. et al. Experimental and numerical analysis in heat flow sensors calibration. J Therm Anal Calorim 138, 2901–2912 (2019). https://doi.org/10.1007/s10973-019-08321-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08321-6