Abstract

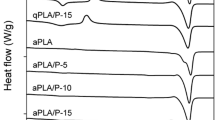

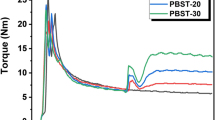

Stereocomplex polylactides (scPLAs) are high-performance biodegradable bioplastics because they show better mechanical properties and heat-resistance than the poly(L-lactide) (PLLA). However, scPLAs retain low flexibility similar to that of PLLA. In this work, a flexible poly(L-lactide)-b-poly(ethylene glycol)-b-poly(L-lactide) (PLLA-PEG-PLLA/PDLA) was melt blended with poly(D-lactide) (PDLA) before compression molding to form scPLA films. The effect of chain extension was investigated. Stereocomplexation of PLLA-PEG-PLLA/PDLA blends improved with PDLA ratio. The thermal stability of both the blends with and without chain extension was improved by stereocomplex formation. The non-chain-extended blend films became very brittle when 40 wt% PDLA was blended. Chain extension enhanced the tensile properties of the blend films. Heat resistance of blend films was significantly improved when the PDLA ratio was increased up to 20 wt%. Dimensional stability to heat at 80 °C of the film samples confirmed the results of heat resistance. The melt-processed scPLA in this work may offer revolutionary improvements in flexible and high heat-resistant bioplastics.

Similar content being viewed by others

References

Rocca-Smith JR, Whyte O, Brachais C, Champion D, Piasente F, Marcuzzo E, Sensidoni A, Debeaufort F, Karbowiak T (2017) Beyond biodegradability of poly(lactic acid): physical and chemical stability in humid environments. ACS Sustain Chem Eng 5:2715–2762

Silva D, Kaduri M, Poley M, Adir O, Krinsky N, Shainsky-Rotiman J, Schroeder A (2018) Biocompatibility, biodegradation and excretion of polylactic acid (PLA) in medical implants and theranostic systems. Chem Eng J 340:9–14

Wu CS, Tsou CH (2019) Fabrication, characterization, and application of biocomposites from poly(lactic acid) with renewable rice husk as reinforcement. J Polym Res 26:44

Saghazadeh S, Rinoldi C, Schot M, Kashaf SS, Sharifi F, Jalilian E, Nuutila K, Giatsidis G, Mostafalu P, Derakhshandeh H, Yue K, Swieszkowski W, Memic A, Tamayol A, Khademhosseini A (2018) Drug delivery systems and materials for wound healing applications. Adv Drug Deliv Rev 127:138–166

Loganathan S, Jacob J, Valapa RB, Thomas S (2018) Influence of linear and branched amine functionalization in mesoporous silica on the thermal, mechanical and barrier properties of sustainable poly(lactic acid) biocomposite films. Polymer 148:149–157

Abudula T, Saeed U, Memic A, Gauthaman K, Hussain MA, Al-Turaif H (2019) Electrospun cellulose nano fibril reinforced PLA/PBS composite scaffold for vascular tissue engineering. J Polym Res 26:110

Nuzzo A, Coiai S, Carroccio SC, Dintcheva NT, Gambarotti C, Filippone G (2014) Heat-resistant fully bio-based nanocomposite blends based on poly(lactic acid). Macromol Mater Eng 299:31–40

Zhang X, Meng L, Li G, Liang N, Zhang J, Zhu Z, Wang R (2016) Effect of nucleating agents on the crystallization behavior and heat resistance of poly(L-lactide). J Appl Polym Sci 133:42999

Tsuji H (2016) Poly(lactic acid) stereocomplexes: a decade of progress. Adv Drug Deliv Rev 107:97–135

Cui C-H, Yan D-X, Pang H, Jia L-C, Xu X, Yang S, Xu J-Z, Li Z-M (2017) A high heat-resistance bioplastic foam with efficient electromagnetic interference shielding. Chem Eng J 323:29–36

Pan G, Xu H, Mu B, Ma B, Yang J, Yang Y (2017) Complete stereo-complexation of enantiomeric polylactides for scalable continuous production. Chem Eng J 328:759–767

El-Khodary E, Fukui Y, Yamamoto M, Yamane H (2017) Effect of the melt-mixing condition on the physical property of poly(L-lactic acid)/poly(D-lactic acid) blends. J Appl Polym Sci 134:45489

Shi X, Jing Z, Zhang G (2018) Influence of PLA stereocomplex crystals and thermal treatment temperature on the rheology and crystallization behavior of asymmetric poly(L-lactide)/poly(D-lactide) blends. J Polym Res 25:71

Cui L, Zhang R, Wang Y, Zhang C, Guo Y (2017) Effect of plasticizer poly(ethylene glycol) on the crystallization properties of stereocomplex-type poly(lactic acid). Wuhan Univ J Natur Sci 22:420–428

Srithep Y, Pholharn D (2017) Plasticizer effect on melt blending of polylactide stereocomplex. e-polymers 17:409–416

Pakkethati K, Baimark Y (2017) Plasticization of biodegradable stereocomplex polylactides with poly(propylene glycol). Polym Sci Series A 59:124–132

Bai H, Deng S, Bai D, Zhang Q, Fu Q (2017) Recent advances in processing of stereocomplex-type polylactide. Macromol Rapid Commun 38:1700454

Liu Y, Shao J, Sun J, Bian X, Feng L, Xiang S, Sun B, Chen Z, Li G, Chen X (2014) Improved mechanical and thermal properties of PLLA by solvent blending with PDLA-b-PEG-b-PDLA. Polym Degrad Stab 101:10–17

Tacha S, Saelee T, Khotasen W, Punyodom W, Molloy R, Worajittiphon P, Meepowpan P, Manokruang K (2015) Stereocomplexation of PLL/PDL-PEG-PDL blends: effects of blend morphology on film toughness. Euro Polym J 69:308–318

Jing Z, Shi X, Zhang G, Lei R (2015) Investigation of poly(lactide) stereocomplexation between linear poly(L-lactide) and PDLA-PEG-PDLA tri-block copolymer. Polym Int 64:1399–1407

Song Y, Wang D, Jiang N, Gan Z (2015) Role of PEG segment in stereocomplex crystallization for PLLA/PDLA-b-PEG-b-PDLA blends. ACS Sustain Chem Eng 3:1492–1500

Jing Z, Shi X, Zhang G (2017) Competitive stereocomplexation and homocrystallization behaviors in the poly(lactide) blends of PLLA and PDLA-PEG-PDLA with controlled block length. Polymers 9:107

Luo C, Yang CM, Xiao W, Yang J, Wang Y, Chen W, Han X (2018) Relationship between the crystallization behavior of poly(ethylene glycol) and stereocomplex crystallization of poly(L-lactic acid)/poly(D-lactic acid). Polym Int 67:313–321

Han L, Yu C, Zhou J, Shan G, Bao Y, Yun X, Dong T, Pan P (2016) Enantiomeric blends of high-molecular-weight poly(lactic acid)/poly(ethylene glycol) triblock copolymers: enhanced stereocomplexation and thermomechanical properties. Polymer 103:376–386

Baimark Y, Rungseesantivanon W, Prakymoramas N (2018) Improvement in melt flow property and flexibility of poly(L-lactide)-b-poly(ethylene glycol)-b-poly(L-lactide) by chain extension reaction for potential use as flexible bioplastics. Mater Des 154:73–80

Tsuji H, Horii F, Hyon S-H, Ikada Y (1991) Stereocomplex formation between enantiomeric poly(lactic acid)s. 2. Stereocomplex formation in concentrated solutions. Macromolecules 24:2719–2724

Tsuji H, Hyon S-H, Ikada Y (1991) Stereocomplex formation between enantiomeric poly(lactic acid)s. 3. Calorimetric studies on blend films cast from dilute solution. Macromolecules 24:5651–5656

Shao J, Xiang S, Bian X, Sun J, Li G, Chen X (2015) Remarkable melting behavior of PLA stereocomplex in linear PLLA/PDLA blends. Ind Eng Chem Res 54:2246–2253

Srisuwan Y, Baimark Y (2018) Controlling stereocomplexation, heat resistance and mechanical properties of stereocomplex polylactide films by using mixtures of low and high molecular weight poly(D-lactide)s. e-polymers 18:485–490

Xie Y, Lan X-R, Bao RY, Lei Y, Cao Z-Q, Yang M-B, Yang W, Wang Y-B (2018) High-performance porous polylactide stereocomplex crystallite scaffolds prepared by solution blending and salt leaching. Mater Sci Eng C 90:602–609

Pan G, Xu H, Ma B, Wizi J, Yang Y (2018) Polylactide fibers with enhanced hydrolytic and thermal stability via complete stereo-complexation of poly(L-lactide) with high molecular weight of 600000 and lower-molecular-weight poly(D-lactide). J Mater Sci 53:5490–5500

Baimark Y, Kittipoom S (2018) Influence of chain-extension reaction on stereocomplexation, mechanical properties and heat resistance of compressed stereocomplex-polylactide bioplastic films. Polymers 10:1218

Corre Y-M, Maazouz A, Reignier J, Duchet J (2014) Influence of the chain extension on the crystallization behavior of polylactide. Polym Eng Sci 54:616–625

Lee S, Kimoto M, Tanaka M, Tsuji H, Nishino T (2018) Crystal modulus of poly(lactic acid), and their stereocomplex. Polymer 138:124–131

Ghalia MA, Dahman Y (2017) Biodegradable poly(lactic acid)-based scaffolds: synthesis and biomedical applications. J Polym Res 24:74

Cui L, Wang Y, Guo Y, Liu Y, Zhao J, Zhang C, Zhu P (2018) Effects of temperature and external force on the stereocomplex crystallization in poly(lactic acid) blends. Adv Polym Technol 37:21743

Tsuji H, Ikada Y (1999) Stereocomplex formation between enantiomeric poly(lactic acid)s. XI Mechanical properties and morphology of solution-cast films Polymer 40:6699–6708

Si W-J, An X-P, Zeng J-B, Chen Y-K, Wang Y-Z (2017) Fully bio-based, highly toughened and heat-resistant poly(L-lactide) ternary blends via dynamic vulcanization with poly(D-lactide) and unsaturated bioelastomer. Sci China Mater 60:1008–1022

Masutani K, Kobayashi K, Kimura Y, Lee CW (2018) Properties of stereo multi-block polylactides obtained by chain-extension of stereo tri-block polylactides consisting of poly(L-lactide) and poly(D-lactide). J Polym Res 25:74

Vadori R, Mohanty AK, Misra M (2013) The effect of mold temperature on the performance of injection molded poly(lactic acid)-based bioplastic. Macromol Mater Eng 298:981–990

Acknowledgements

This work was supported by Mahasarakham University (Grant no. 6105029) and The Center of Excellence for Innovation in Chemistry (PERCH-CIC), Office of the Higher Education Commission, Ministry of Education, Thailand.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 149 kb)

Rights and permissions

About this article

Cite this article

Baimark, Y., Pasee, S., Rungseesantivanon, W. et al. Flexible and high heat-resistant stereocomplex PLLA-PEG-PLLA/PDLA blends prepared by melt process: effect of chain extension. J Polym Res 26, 218 (2019). https://doi.org/10.1007/s10965-019-1881-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1881-7