Abstract

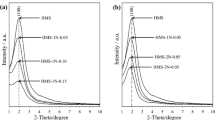

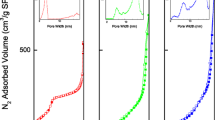

Six surface active compounds containing: hexadecyltrimethylammonium [HDTMA], dodecyltrimethylammonium [DDTMA] or didecyldimethylammonium [DDA] cation and tetrafluoroborate [BF4] or acetate [OAc] anion were synthesized, purified and characterized, and subsequently applied for the synthesis of mesoporous silica materials of MCM-41 type. The materials were characterized using X-ray diffraction, Scanning Electron microscopy, and nitrogen physisorption method. Their structures were compared with that of reference MCM-41 material obtained with the conventional template [HDTMA][Br]. Nanosized silica spheres with size distribution in the range of 200–800 nm are obtained with the novel templates. The pore size of the obtained materials was in the range of 2.1–3.1 nm, and it was dependent only on the cation structure of the templates. The MCM-41 materials obtained with the acetate-based templates were characterized with a higher specific surface area in comparison with the reference material. On the basis of SEM, XRD and nitrogen physisorption data could be concluded that all tetraalkylammonium acetates used as templates lead to mesoporous silica nanospheres with very good textural characteristics, while in case of tetraalkylammonium tetrafluoroborates the best results in terms of particle uniformity and surface properties are obtained with [DDTMA][BF4]. MCM-41-[HDTMA][OAc] exhibited excellent loading capacity (374.1 mg/g) for the cyclic peptide antibiotic bacitracin, and moderate to good loading capacity for larger peptide and proteins such as insulin (70.3 mg/g) and lipase from porcine pancreas (70.8 mg/g).

Similar content being viewed by others

References

K.S.W. Sing,D.H. Everett, R.A.W. Haul, L. Moscou, R.A. Pierotti, J. Rouquerol, T. Siemieniewska, Pure Appl. Chem. 57, 603 (1985)

Y. Feng, N. Panwar, D.J.H. Tng, S.C. Tjin, K. Wang, K.-T. Yong, Coord. Chem. Rev. 319, 86 (2016)

S. Zuo, X. Wang, P. Yang, C. Qi, Catal. Commun. 94, 52 (2017)

K. Yoncheva, M. Popova, A. Szegedi, J. Mihaly, B. Tzankov, N. Lambov, S. Konstantinov, V. Tzankova, F. Pessina, M. Valoti, J. Solid State Chem. 211, 154 (2014)

H.-J. Kim, H.-C. Yang, D.-Y. Chung, I.-H. Yang, Y.J. Choi, J.-K. Moon, J. Chem. 2015, 202867 (2015)

A. Liberman, N. Mendez, W.C. Trogler, A.C. Kummel, Surf. Sci. Rep. 69(2–3), 132 (2014)

Z. Zhou, M. Hartmann, Chem. Soc. Rev. 42, 3894 (2013)

P. Kipkemboi, A. Fogden, V. Alfredsson, K. Flodström, Langmuir 17, 5398 (2001)

N. Venkatathri, Mater. Sci. Eng. C 28, 1260 (2008)

J.-Y. Zheng, J.-B. Pang, K.-Y. Qiu, Y. Wei, J. Inorgan. Organomet. Polym. 10(3), 103 (2000)

N. Venkatathri, R. Srivastava, D.S. Yun, J.W. Yoo, Microporous Mesoporous Mater. 112, 147 (2008)

C. Gerardin, J. Reboul, M. Bonne, B. Lebeau, Chem. Soc. Rev. 42, 4217 (2013)

J.C. Vartuli, K.D. Schmitt, C.T. Kresge, W.J. Roth, M.E. Leonowicz, E.W. Sheppardt, S.B. McCullen, S.D. Hellring, J.S. Beck, J.L. Schlenker, D.H. Olson, E.W. Sheppard, Chem. Mater. 6, 2317 (1994)

J.S. Beck, J.C. Vartuli, W.J. Roth, M.E. Leonowicz, C.T. Kresge, K.D. Schmitt, C. T-. W. Chu, D.H. Olson, E.W. Sheppard, S.B. McCullen, J.B. Higgins, J.L. Schlenkert, J. Am. Chem. Soc. 114, 10834 (1992)

Q. Huo, R. Leon, P.M. Petroff, G.D. Stucky, Science 268, 1324 (1995)

D. Zhao, Q. Huo, J. Feng, J. Kim, Y. Han, G.D. Stucky, Chem. Mater. 11, 2668 (1999)

L. Han, S. Che, Chem. Soc. Rev 42, 3740 (2013)

M. Antonietti, D. Kuang, B. Smarsly, Y. Zhou, Angew. Chem. Int. Ed. 43, 4988 (2004)

A. Zukal, H. Siklova, J. Cejka, M. Thommes, Adsorption 13, 247 (2007)

B. Trewyn, C.M. Whitman, V.S.-Y. Lin, Nano Lett. 4(11), 2139 (2004)

T. Wang, H. Kaper, M. Antonietti, B. Smarsly, Langmuir 23, 1489 (2007)

A. Zukal, M. Thommes, J. Cejka, Microporous Mesoporous Mater. 104, 52 (2007)

Y.-J. Yu, J.-L. Xing, J.-L. Pang, S.-H. Jiang, K.-F. Lam, T.-Q. Yang, Q.-S. Xue, K. Zhang, P. Wu, ACS Appl. Mater. Interf. 6(24), 22655 (2014)

A.K.L. Yuen, F. Heinroth, A.J. Ward, A.F. Masters, T. Maschmeyer, Microporous Mesoporous Mater. 148, 62 (2012)

Y. Zhou, J.H. Schattka, M. Antonietti, Nano Lett. 4(3), 478 (2004)

S. Dai, Y.H. Ju, H.J. Gao, J.S. Lin, S.J. Pennycook, C.E. Barnes, Chem. Commun. 243, 3 (2000)

H. Sanaeishoar, M. Sabbaghan, F. Mohave, Microporous Mesoporous Mater. 217, 219 (2015)

B. Tan, H.-J. Lehmler, S.M. Vyas, B.L. Knutson, S.E. Rankin, Chem. Mater. 17, 916 (2005)

M. Grün, K. Unger, A. Matsumoto, K. Tsutsumi, Microporous Mesoporous Mater. 27(2–3), 207 (1999)

H. Zhang, J. Wu, L. Zhou, D. Zhang, L. Qi, Langmuir 23(3), 1107 (2007)

L.M. Pera, M.D. Baigori, A. Pandey, G.R. Castro, Industrial Biorefineries and White Biotechnology (Elsevier, Amsterdam, 2015) pp. 391–408

E. Skorupska, A. Jeziorna, P. Paluch,. M.J. Potrzebowski, Mol. Pharm. 11, 1512 (2014)

T. Heikkilä, J. Salonen, J. Tuura, N. Kumar, T. Salmi, D.Yu.. Murzin, M.S. Hamdy, G. Mul, L. Laitinen, A.M. Kaukonen, J. Hirvonen, V.-P. Lehto, Drug Deliv. 14, 337 (2007)

N.V. Roik, L.A. Belyakova, M.O. Dziazko, Adsorpt. Sci. Technol. 35(1–2), 86 (2017)

M. Kosmulski, in Chemical Properties of Material Surfaces, ed. by H. T. Arthur (Marcel Dekker, Inc., New York, 2001), pp. 65–293

J. Kraineva, V. Smirnovas, R. Winter, Langmuir 23, 7118 (2007)

Acknowledgements

The authors would like to thank Nicola Zuccheto and Dr. Dominik Brühwiler form the Institute of Chemistry and Biotechnology, Zurich University of Applied Sciences, Switzerland for the nitrogen physisorption and SEM measurements.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Guncheva, M., Dimitrov, M., Ossowicz, P. et al. Tetraalkylammonium acetates and tetraalkylammonium tetrafluoroborates as new templates for room-temperature synthesis of mesoporous silica spheres. J Porous Mater 25, 935–943 (2018). https://doi.org/10.1007/s10934-017-0505-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-017-0505-z