Abstract

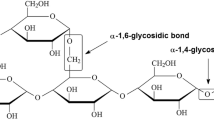

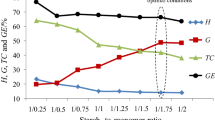

Properties and biodegradation of thermoplastic starch obtained using granular starches grafted with poly(lactic acid) (St-g-PLA) were studied. The grafting of PLA on the starch granule was verified by the emergence of the carbonyl group in the FTIR spectra and the higher diameter of the grafted starch granule. Thermoplastic starch from ungrafted granular starch (TPS) and grafted granular starch (TPGS) were obtained by mixing ungrafted or grafted starch with water, glycerol or sorbitol in a mixer. TPS and TPGS behave as plastic materials, and their mechanical properties depend on the type of plasticizer used. Materials with glycerol as the plasticizer exhibited less rigidity than the materials obtained using sorbitol. The presence of starch-g-PLA results in an increase in the elongation of the thermoplastic material. TPS and TPGS were hydrolysed by amylolytic enzymes in short-time periods compared to granular PLA-grafted starches.

Similar content being viewed by others

Change history

13 February 2020

The original version of this article unfortunately contained an error in Reference 7. The correct reference 7 should read as the following,

13 February 2020

The original version of this article unfortunately contained an error in Reference 7. The correct reference 7 should read as the following,

References

Zuo Y, He X, Li P, Li W, Wu Y (2019) Polymers 11:72. https://doi.org/10.3390/polym11010072

Salimi K, Şen SC, Ersan HY, Pişkin E (2017) J Appl Polym Sci 134:44490. https://doi.org/10.1002/app.44490

Zain AHM, Wahab MK, Ismail H (2017) J Polym Environ 26:691–700. https://doi.org/10.1007/s10924-017-0978-5

Gong Q, Wang L-Q, Tu K (2006) Carbohydr Polym 64:501

Ibrahim N, Ab Wahab MK, Uylan DN, Ismail H (2017) BioResources 12:3076

Lu DR, Xiao CM, Xu SJ (2009) Express Polym Lett 3:366

Esmaeli M, Pircheraghi G, Bagheri R, Altstädt V (2019) Polym Adv Technol 30:839

Arboleda GA, Montilla CE, Villada HS, Varona GA (2015) Int J Polym Sci 2015:1

Schmitt H, Guidez A, Prashantha K, Soulestin J, Lacrampe MF, Krawczak P (2015) Carbohydr Polym 115:364

Ren J, Fu H, Ren T, Yuan W (2009) Carbohydr Polym 77:576

Chen L, Qiu X, Deng M, Hong Z, Luo R, Chen X, Jing X (2005) Polymer 46:5723

Vikman M, Hulleman SHD, Van Der Zee M, Myllärinen P, Feil H (1999) J Appl Polym Sci 74:2594

Aranda-García FJ, González-Núñez R, Jasso-Gastinel CF, Mendizábal E (2015) Int J Polym Sci 2015:1

Carmona VB, Corrêa AC, Marconcini JM, Mattoso LHC (2015) J Polym Environ 23:83

Tena-Salcido CS, Rodríguez-González FJ, Méndez-Hernández ML, Contreras-Esquivel JC (2008) Polym Bull 60:677

Li H, Huneault MA (2011) J Appl Polym Sci 119:2439

Kaewtatip K, Tanrattanakul V, Szécsényi KM, Pavlicevic J, Budinski-Simendic J (2010) J Thermal Anal Calorim 102:1035

Canché-Escamilla G, Canché-Canché M, Duarte-Aranda S, Cáceres-Farfán M, Borges-Argáez R (2011) Carbohydr Polym 86:1501

Li M-C, Lee JK, Cho UR (2012) J Appl Polym Sci 125:405

Rutot D, Degée P, Narayan R, Dubois P (2000) Compos Interfaces 7:215

Ferrarezi MMF, de Oliveira Taipina M, Escobar da Silva LC, Gonçalves MdC (2013) J Polym Environ 21:151

Xu Q, Wang Q, Liu L (2008) J Appl Polym Sci 107:2704

Inkinen S, Hakkarainen M, Albertsson A-C, Södergård A (2011) Biomacromol 12:523

Zerroukhi A, Jeanmaire T, Raveyre C, Ainser A (2012) Starch/Stärke 64:613

Najemi L, Jeanmaire T, Zerroukhi A, Raihane M (2010) Starch/Stärke 62:147

Shao J, Zhao J, Zhao Y, Yan Y, Qiu Z (2013) Polym Bull 70:59

Vera-Pacheco M, Vázquez-Torres H, Canché-Escamilla G (1993) J Appl Polym Sci 47:53

ASTM (2014) ASTM International, West Conshohocken, PA

Moreno-Chulim MV, Barahona-Pérez F, Canché-Escamilla G (2003) J Appl Polym Sci 89:2764

Colthup NB, Daly LH, Wiberley SE (1990) Introduction to infrared and raman spectroscopy. Elsevier, New York, pp 218–440

Xie XS, Liu Q, Cui SW (2006) Food Res Int 39:332

Casarrubias-Castillo MG, Méndez-Montealvo G, Rodríguez-Ambriz SL, Sánchez-Rivera MM, Bello-Pérez LA (2012) Agrociencia (Montecillo) 46:455

Araújo MA, Cunha AM, Mota M (2004) Biomaterials 25:2687

Azevedo HS, Reis RL (2005) In: Reis RL, San Román J (eds) Biodegradable systems in tissue engineering and regenerative medicine. CRC Press, Boca Ratón, pp 177–201

Dumoulin Y, Cartilier LH, Mateescu MA (1999) J Control Release 60:161

Esmaeili M, Pircheraghi G, Bagheri R (2017) Polym Int 66:809–819

Fang J, Fowler P (2003) J Food Agric Environ 1:82

Forssell PM, Mikkilä JM, Moates GK, Parker R (1997) Carbohydr Polym 34:275

Van Soest JJG, Essers P (1997) J Macromol Sci A 34:1665

Van Soest JJG, Hulleman SHD, De Wit D, Vliegenthart JFG (1996) Ind Crops Prod 5:11

Van Soest JJG, Benes K, de Wit D, Vliegenthart JFG (1996) Polymer 37:3543

Van Soest JJG, De Wit D, Vliegenthart JFG (1996) J Appl Polym Sci 61:1927

Van Soest JJG (1996) Starch plastics: structure-property relationships. P&L Press, Universiteit Utrecht, Wageningen, pp. 168

Hulleman SHD, Janssen FHP, Feil H (1998) Polymer 39:2043

Da Ro´z AL. Carvalho AJF, Gandini A, Curvelo AAS (2006) Carbohydr Polym 63:417

Acknowledgements

The authors wish to thank the National Council of Science and Technology in México (CONACyT) for financial support of the Ph.D. thesis of one of the authors (Cuevas-Carballo, Z. B.). The X-ray diffraction analysis was performed at the National Laboratory of Nano and Biomaterials (financed by Fomix-Yucatán and CONACyT), CINVESTAV-IPN. Mérida Unit. We thank Dr. Patricia Quintana for access to LANNBIO and M. C. Daniel Aguilar for technical support in obtaining the diffractograms.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cuevas-Carballo, Z.B., Duarte-Aranda, S. & Canché-Escamilla, G. Properties and Biodegradation of Thermoplastic Starch Obtained from Grafted Starches with Poly(lactic acid). J Polym Environ 27, 2607–2617 (2019). https://doi.org/10.1007/s10924-019-01540-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01540-w