Abstract

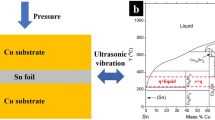

The competitive growth of Cu3Sn and Cu6Sn5 in the multi-reflow processes induced by temperature, time, and cooling rate was systematically studied in this work. Results indicated that the thickness proportion of Cu3Sn in the IMC layer was highly promoted in the temperature-increased multi-reflow process and slightly increased with a fluctuation in the isothermal multi-reflow process, while obviously decreased in the temperature-decreased multi-reflow process. The proportion of Cu3Sn grew following the increase of reflow temperature, time, and cooling rate and the thickness of Cu3Sn formed at the central of the Cu6Sn5 bottom was higher than that formed at the edge. The results have a significant meaning in understanding and controlling the competitive growth of Cu3Sn and Cu6Sn5 and improving the reliability of solder joints.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

F. Jensen, C. Lea, Electrochemical publications limited. Qual. Reliab. Eng. Int. 5(2), 182–182 (2010)

D.R. Frear, J.W. Jang, J.K. Lin et al., Pb-free solders for flip-chip interconnects. JOM 53(6), 28–33 (2001)

K.N. Tu, C. Chen, A.T. Wu, Stress analysis of spontaneous Sn whisker growth. J. Mater. Sci.: Mater. Electron. 18, 269–281 (2007)

H. Ma, J.C. Suhling, A review of mechanical properties of lead-free solders for electronic packaging. J. Mater. Sci. 44(5), 1141–1158 (2009)

L. Qu, N. Zhao, H. Zhao, M. Huang, H. Ma, In situ study of the real-time growth behavior of Cu6Sn5at the Sn/Cu interface during the soldering reaction. Scr. Mater. 72, 43–46 (2014)

M.J. Wolf, G. Engelmann, L. Dietrich et al., Flip chip bumping technology status and update. Nucl. Instrum. Methods Phys. Res. A 565(1), 290–295 (2006)

Q. Jiang, S.H. Zhang, J.C. Li, Grain size-dependent diffusion activation energy in nanomaterials. Solid State Commun. 130(9), 581–584 (2004)

Y.D. Qu, X.L. Liang, X.Q. Kong et al., Size-dependent cohesive energy, melting temperature, and Debye temperature of spherical metallic nanoparticles. Phys. Met. Metallogr. 118(6), 528–534 (2017)

T.K. Lee, B. Zhou, L. Blair, K.C. Liu, T.R. Bieler, Sn-Ag-Cu solder joint microstructure and orientation evolution as a function of position and thermal cycles in ball grid arrays using orientation imaging microscopy. J. Electron. Mater. 39(12), 2588–2597 (2010)

M.R. Harrison, J.H. Vincent, H. Steen, Lead-free reflow soldering for electronics assembly. Solder. Surf. Mt. Technol. 13(3), 21–38 (2001)

W.K. Choi, H.M. Lee, Effect of sodering and aging time on interfacial microstructure and growth of intermetallic compounds between Sn-3.5Ag solder alloy and Cu substrate. J. Electron. Mater. 29(10), 1207–1213 (2000)

T.X. Yang, N. Razak, M.H. Husain et al., Temperature dependency of the growth rate of (Cu, Ni)6Sn5 on Cu-xNi substrates. IOP Conf. Ser. Mater. Sci. Eng. 701, 012007 (2019)

Y.S. Huang, H.Y. Hsiao, C. Chen, K.N. Tu, The effect of a concentration gradient on interfacial reactions in micro-bumps of Ni/Sn-Ag/Cu during liquid-state soldering. Scr. Mater. 66(10), 741–744 (2012)

C.M. Liu, C.E. Ho, W.T. Chen et al., Reflow soldering and isothermal solid-state aging of Sn-Ag eutectic solder on Au/Ni surface finish. J. Electron. Mater. 30(9), 1152–1156 (2001)

C.K. Wong, J. Pang, J.W. Tew et al., The influence of solder volume and pad area on Sn–3.8Ag–0.7Cu and Ni UBM reaction in reflow soldering and isothermal aging. Microelectron. Reliab. 48(4), 611–621 (2008)

K.H. Prakash, T. Sritharan, Acta Mater. 49, 2481 (2001)

H.K. Kim, K.N. Tu, Kinetic analysis of the soldering reaction between eutectic Sn Pb alloy and Cu accompanied by ripening. Phys. Rev. B: Condens. Matter 53(23), 16027 (1996)

X. Deng, G. Piotrowski, J. Williams et al., Influence of initial morphology and thickness of Cu6Sn5 and Cu3Sn intermetallic on growth and evolution during thermal aging of Sn-Ag solder/Cu joints. J. Electron. Mater. 32(12), 1403–1413 (2003)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51871040).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shang, M., Dong, C., Yao, J. et al. Competitive growth of Cu3Sn and Cu6Sn5 at Sn/Cu interface during various multi-reflow processes. J Mater Sci: Mater Electron 32, 22771–22779 (2021). https://doi.org/10.1007/s10854-021-06711-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06711-x