Abstract

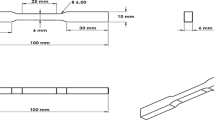

In this study, we focus on the dynamic failure property of A6N01S-T5 aluminum alloy use for high-speed trains. The method of split Hopkinson tensile bar (SHTB) and three-dimensional (3D) digital image correlation (DIC) was put forward to find the dynamic mechanical properties and dynamic failure strain of A6N01S-T5 aluminum alloy, and on the basis of this, Johnson–Cook model constitutive parameters and dynamic failure strain parameters were obtained through a series of static and dynamic tests. An important character of this method was that the sandwich structure from the true high-speed train was used in penetration test, followed by the numerical calculation of the same working condition using LS-DYNA. Then we compare the experimental results with simulation results mentioned above in terms of failure morphology in structure and the bullet speed throughout the entire process to verify the accuracy of the parameter. The experimental results provide a data basis for the crash simulation model of high-speed trains, in turn to optimize the structural design and whole efficiency.

Graphical abstract

Similar content being viewed by others

References

Chen, H.G., Administration, J.R.: Performance of the a6n01s-t5 aluminum alloy and the welding joint for high speed train at low temperature. Electr. Weld. Mach. 46, 77–82 (2016) (in Chinese)

Gou, G.Q., Huang, N., Chen, H., et al.: Research on corrosion behavior of A6N01S-T5 aluminum alloy welded joint for high-speed trains. J. Mech. Sci. Technol. 26, 1471–1476 (2012)

Yonetani, H.: Laser-mig hybrid welding to aluminium alloy carbody shell for railway vehicles. Weld. Int. 22, 701–704 (2008)

Yu, J., Gou, G., Zhang, L., et al.: Ultrasonic impact treatment to improve stress corrosion cracking resistance of welded joints of aluminum alloy. J. Mater. Eng. Perform. 25, 3046–3056 (2016)

Zhu, Z.Y., Chen, P., Zhou, H.M., et al.: Effect of the welding heat input on residual stresses in butt-weld of high-speed train. In: International Conference on Materials and Products Manufacturing Technology, Chengdu, October 28–30 (2011)

Dorn, J.E., Pietrokowsky, P., Tietz, T.E.: The effect of alloying elements on the plastic properties of aluminum alloys. JOM 2, 933–943 (1950)

Mrówka-Nowotnik, G.: Influence of chemical composition variation and heat treatment on microstructure and mechanical properties of 6xxx alloys. Arch. Metall. Mater. 46, 98–107 (2010)

Liu, Y.L., Kang, S.B., Kim, H.W.: The complex microstructures in an as-cast Al–Mg–Si alloy. Mater. Lett. 41, 267–272 (1999)

Irving, B.: Welding the four most popular aluminum alloys. Weld. J. 73(2), 51–55 (1994)

Bergsma, S.C.: Aluminum-magnesium-silicon alloy and treatment schedule, for use in the transport industry. US Patent 5961752-A (1999)

Troeger, L.P., Starke, E.A.: Microstructural and mechanical characterization of a superplastic 6xxx aluminum alloy. Mater. Sci. Eng. 277, 102–113 (2000)

Ito, T., Ishikawa, M., Otsuka, M., et al.: Ductility of 6xxx aluminum alloys at high temperature. J. Jpn. Inst. Ligh. Met. 53, 114–120 (2003)

Schulz, P., Berneder, J., Uffelmann, D., et al.: Advanced 5xxx-, 6xxx- and 7xxx-aluminium alloys for applications in automotive and consumer electronics. Mater. Sci. Forum 690, 451–454 (2011)

Zhong, H., Rometsch, P.A., Cao, L.F., et al.: The influence of Mg/Si ratio and Cu content on the stretch formability of 6xxx aluminium alloys. Mater. Sci. Eng. 651, 688–697 (2016)

Koo, J.S., Cho, H.J.: Theoretical method for predicting the weight reduction rate of a box-type car body for rolling stock by material substitution design. Int. J. Automot. Technol. 10, 355–363 (2009)

Kang, S.G., Shin, K.B., Ko, T.H., et al.: Lightweight design of car bodies for double deck high-speed trains. J. Korean Soc. Manuf. Technol. Eng. 24, 177–185 (2015) (in Korean)

Gao, Y.H., Shi, X.F., Xie, S.M., et al.: Sensitivity analysis and lightweight design for high-speed train car body. J. Rail Way Sci. Eng. 14, 885–891 (2017) (in Chinese)

Rochard, B.P., Schmid, F.: Benefits of lower-mass trains for high speed rail operations. Proc. Inst. Civil Eng. Transp. 157, 51–64 (2004)

Wennberg, D., Stichel, S., Wennhage, P.: Benefits of weight reduction in high-speed train operations. ZEV Rail Glasers Annalen 137, 77–87 (2013)

Ezra, A.A., Fay, R.J.: An assessment of energy absorbing devices for prospective use in aircraft impact situations. in: Dynamic behaviour of structures, pp. 225–246. Pergamon, London (1972)

Yang, Z., Yu, Y.Y., Wei, Y.P., et al.: Crushing behavior of a thin-walled circular tube with internal gradient grooves fabricated by SLM 3D printing. Thin Walled Struct. 111, 1–8 (2017)

Li, Z.G., Yang, H.F., Hu, X.W., et al.: Experimental study on the crush behavior and energy-absorption ability of circular magnesium thin-walled tubes and the comparison with aluminum tubes. Eng. Struct. 164, 1–13 (2018)

Spigarelli, S., Evangelista, E., Mcqueen, H.J.: Study of hot workability of a heat treated AA6082 aluminum alloy. Scr. Mater. 49, 179–183 (2003)

Garrett, R.P., Lin, J., Dean, T.A.: An investigation of the effects of solution heat treatment on mechanical properties for aa 6xxx alloys: experimentation and modelling. Int. J. Plast 21, 1640–1657 (2005)

Werber, A., Liewald, M.: Influence of pre-strain and heat treatment on mechanical properties of aluminum sheet. Int. J. Mater. Form. 5, 307–315 (2012)

Zhong, H., Rometsch, P., Estrin, Y.: Effect of alloy composition and heat treatment on mechanical performance of 6xxx aluminum alloys. Trans. Nonferrous Met. Soc. China 24, 2174–2178 (2014)

Shi, L., Yang, H., Guo, L.G., et al.: Constitutive modeling of deformation in high temperature of a forging 6005A aluminum alloy. Mater. Des. 54, 576–581 (2014)

Zhu, D.J., Mobasher, B., Rajan, S.D., et al.: Characterization of dynamic tensile testing using aluminum alloy 6061-T6 at intermediate strain rates. J. Eng. Mech. 137, 669–679 (2011)

Vilamosa, V., Clausen, A.H., Børvik, T., et al.: Behaviour of Al–Mg–Si alloys at a wide range of temperatures and strain rates. Int. J. Impact Eng. 86, 223–239 (2015)

Zhang, D.N., Shangguan, Q.Q., Xie, C.J., et al.: A modified Johnson–Cook model of dynamic tensile behaviors for 7075–T6 aluminum alloy. J. Alloy. Compd. 619, 186–194 (2015)

Singh, R., Chauhan, S., Gope, P.C.: Fracture behavior of welded aluminum alloy at high strain rates. Proc. Eng. 173, 1246–1250 (2017)

Chen, X.Z., Peng, Y., Peng, S., et al.: Flow and fracture behavior of aluminum alloy 6082-T6 at different tensile strain rates and triaxialities. PLoS ONE 12, e0181983 (2017)

Sun, D.Z., Krawiec, M., Hooputra, H.: Characterization and modelling of the damage behavior of extruded aluminum profiles for crash simulations. Mater. Sci. Forum 877, 674–679 (2016)

Børvik, T., Hopperstad, O.S., Berstad, T.: On the influence of stress triaxiality and strain rate on the behaviour of a structural steel. Part II. Numerical study. Eur. J. Mech. A Solids 22, 15–32 (2003)

Acknowledgements

This work was supported by the National Department of Science and Technology (Grant 2016YFB1200505).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Z., Yu, Y., Yang, Z. et al. Dynamic experimental studies of A6N01S-T5 aluminum alloy material and structure for high-speed trains. Acta Mech. Sin. 35, 763–772 (2019). https://doi.org/10.1007/s10409-018-0830-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-018-0830-8