Abstract

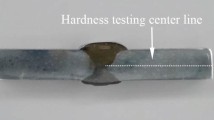

For high speed trains, safety is of utmost importance. Salt fog corrosion, intergranular corrosion tests were employed to observe the corrosion behavior of welded joint of A6N01S-T5 aluminum alloy of high-speed trains. Tensile strength and hardness changed after corrosion was tested. The micro morphologies were observed by metalloscope and laser confocal scanning microscope (LCSM). The corrosion loss and corrosion loss ratio were also investigated. The results showed that the heat affected zone (HAZ) was the most sensitive to corrosion in welded joint in the salt fog corrosion test. The potential of the corrosion of the intermetallic compound on the surface was different from the Al matrix potential, which easily generated corrosion micro-batteries that generated the corrosion pit. The weld zone was the most sensitive to corrosion in the welded joint in the intergranular corrosion test, because much corrosion produced an intermetallic phase such as CuAl2, MgZn2, Mg5Al8, which formed the deficient Cu or Mg zone potential. The potential is low, which acted as an anode and corroded. The residual stress test on the weld of the A6N01S-T5 of the W1 of the exterior surface of roof of high speed train showed there was distributed high tensile stress and compressed stress in the weld zone, HAZ zone and matrix zone. The defects will spread under the high stress and make the corrosion become severe.

Similar content being viewed by others

References

N. Hideo, Innovation of railway transport and development of people’s living condition-the Japanese experience, China Railway Publishing House, Beijing, China (2002).

C. S. Paglia and R. G. Buchheit, A look in the corrosion of aluminum alloy friction stir welds, Scripta Materialia, 58(6) (2008) 383–387.

A. Raman and B. Kuban, The application of infrared spectroscopy to the study of atmospheric rust systems-I Standard spectra and illustrative applications to identify rust phases in natural atmospheric corrosion products, Corrosion Science, 32(12) (1991) 1295–1306.

C. P. Chan and T. M. Yue, The effect of excimer laser surface treatment on pitting corrosion fatigue behavior of aluminum alloy 7075, Journal of Materials Science, 38(7) (2003) 2689–2702.

F. T. Gong and C. J. Fu, The corrosion behavior of A6005A aluminum alloy welding joints, Journal of Dalian Jiaotong University, 30(5) (2009) 67.

U. Zupanc and J. Grum, The effect of pitting corrosion on fatigue performance of shot-peened aluminum alloy 7075-T651, Journal of Material Processing, 210(2) (2010) 1197.

M. Jariyaboon and A. J. Davenport, The effect of welding parameters on the corrosion behavior of friction stir welded AA2024-T351, Corrosion Science, 49(4) (2007) 877.

D. A. Wadeson, X. Zhou and G. E. Thompson et al., Corrosion behavior of friction stir welded AA7108 T79 aluminum alloy, Corrosion Science, 48(3) (2006) 887–897.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Jai Hak Park.

Guo-qing Gou is a lecturer at the School of Materials Science and Engineering, Southwest Jiaotong University (SWJTU), China. His research interest is welding technology and non-destructive testing. At least 20 of his papers have already been published.

Nan Huang is a professor and Ph.D supervisor at the School of Materials Science and Engineering, Southwest Jiaotong University (SWJTU), China. His research interest is coating technology and materials protection. At least 100 of his papers have already been published.

Rights and permissions

About this article

Cite this article

Gou, G., Huang, N., Chen, H. et al. Research on corrosion behavior of A6N01S-T5 aluminum alloy welded joint for high-speed trains. J Mech Sci Technol 26, 1471–1476 (2012). https://doi.org/10.1007/s12206-012-0342-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-012-0342-6