Abstract

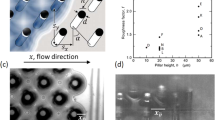

This study considers the spreading of a Newtonian and perfectly wetting liquid in a square array of cylindric micropillars confined between two plates. We show experimentally that the dynamics of the contact line follows a Washburn-like law which depends on the characteristics of the micropillar array (height, diameter and pitch). The presence of pillars can either enhance or slow down the motion of the contact line. A theoretical model based on capillary and viscous forces has been developed in order to rationalize our observations. Finally, the impact of pillars on the volumic flow rate of liquid which is pumped in the microchannel is inspected.

Similar content being viewed by others

References

Bocquet L, Barrat JL (2007) Flow boundary conditions from nano-to micro-scales. Soft Matter 3(6):685–693

Del Campo A, Greiner C (2007) Su-8: a photoresist for high-aspect-ratio and 3d submicron lithography. J Micromech Microeng 17(6):R81

Folch A, Ayon A, Hurtado O, Schmidt M, Toner M (1999) Molding of deep polydimethylsiloxane microstructures for microfluidics and biological applications. J Biomech Eng 121(1):28–34

Gamrat G, Favre-Marinet M, Le Person S, Baviere R, Ayela F (2008) An experimental study and modelling of roughness effects on laminar flow in microchannels. J Fluid Mech 594:399–423

Gunda N, Joseph J, Tamayol A, Akbari M, Mitra S (2013) Measurement of pressure drop and flow resistance in microchannels with integrated micropillars. Microfluidics Nanofluidics 14(3–4):711–721

Hale R, Bonnecaze R, Hidrovo C (2014a) Optimization of capillary flow through square micropillar arrays. Int J Multiph Flow 58:39–51

Hale R, Ranjan R, Hidrovo C (2014b) Capillary flow through rectangular micropillar arrays. Int J Heat Mass Transf 75:710–717

Ishino C, Reyssat M, Reyssat E, Okumura K, Quere D (2007) Wicking within forests of micropillars. EPL (Europhys Lett) 79(5):56,005

Kim S, Moon MW, Lee KR, Lee DY, Chang Y, Kim HY (2011) Liquid spreading on superhydrophilic micropillar arrays. J Fluid Mech 680:477–487

Kissa E (1996) Wetting and wicking. Text Res J 66(10):660–668

Mai T, Lai C, Zheng H, Balasubramanian K, Leong K, Lee P, Lee C, Choi W (2012) Dynamics of wicking in silicon nanopillars fabricated with interference lithography and metal-assisted chemical etching. Langmuir 28(31):11,465–11,471

Mognetti B, Yeomans J (2009) Capillary filling in microchannels patterned by posts. Phys Rev E 80(5):056,309

Mohammadi A, Floryan J (2013) Pressure losses in grooved channels. J Fluid Mech 725:23–54

Nagrath S, Sequist LV, Maheswaran S, Bell DW, Irimia D, Ulkus L, Smith MR, Kwak EL, Digumarthy S, Muzikansky A et al (2007) Isolation of rare circulating tumour cells in cancer patients by microchip technology. Nature 450(7173):1235–1239

Sadiq T, Advani S, Parnas R (1995) Experimental investigation of transverse flow through aligned cylinders. Int J Multiph Flow 21(5):755–774

Op de Beeck J, De Malsche W, Tezcan D, De Moor P, Desmet G (2012) Impact of the limitations of state-of-the-art micro-fabrication processes on the performance of pillar array columns for liquid chromatography. J Chromatogr A 1239:35–48

Schwiebert MK, Leong WH (1996) Underfill flow as viscous flow between parallel plates driven by capillary action. Compon Packag Manuf Technol Part C IEEE Trans 19(2):133–137

Semprebon C, Forsberg P, Priest C, Brinkmann M (2014) Pinning and wicking in regular pillar arrays. Soft Matter 10(31):5739–5748

Spruijt E, Le Guludec E, Lix C, Wagner M (2015) Liquid filmification from menisci. EPL (Europhys Lett) 112(1):16,002

Tamayol A, Bahrami M (2009) Analytical determination of viscous permeability of fibrous porous media. Int J Heat Mass Transf 52(9):2407–2414

Tamayol A, Yeom J, Akbari M, Bahrami M (2013) Low reynolds number flows across ordered arrays of micro-cylinders embedded in a rectangular micro/minichannel. Int J Heat Mass Transf 58(1):420–426

Thompson P, Robbins M (1989) Simulations of contact-line motion: slip and the dynamic contact angle. Phys Rev Lett 63(7):766

Tien C, Sun K (1971) Minimum meniscus radius of heat pipe wicking materials. Int J Heat Mass Transf 14(11):1853–1855

Vangelooven J, De Malsche W, De Beeck JO, Eghbali H, Gardeniers H, Desmet G (2010) Design and evaluation of flow distributors for microfabricated pillar array columns. Lab Chip 10(3):349–356

Wan J, Zhang WJ, Bergstrom D (2008) Experimental verification of models for underfill flow driven by capillary forces in flip-chip packaging. Microelectron Reliab 48(3):425–430

Washburn EW (1921) The dynamics of capillary flow. Phys Rev 17(3):273

Xiao R, Wang EN (2011) Microscale liquid dynamics and the effect on macroscale propagation in pillar arrays. Langmuir 27(17):10,360–10,364

Zimmermann M, Schmid H, Hunziker P, Delamarche E (2007) Capillary pumps for autonomous capillary systems. Lab Chip 7(1):119–125

Acknowledgments

This research has been funded by the Inter-university Attraction Poles Programme (IAP 7/38 MicroMAST) initiated by the Belgian Science Policy Office. SD thanks the FNRS for financial support. We acknowledge Mathilde Reyssat, Tristan Gilet and Pierre Colinet for fruitful discussions and valuable comments. We are grateful to Stéphanie Van Loo for precious advices concerning the realization of the PDMS microchannels.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Equation (12) allows determining the critical pillar density \(\phi _c\) in order to have \(D=D_0\) with \(\phi _c \ne 0\). The critical density verifies the relation

which has a solution only if \(\overline{h}>0.5\). Equation (17) is solved numerically as a function of \(\overline{h}\) and the solution is indicated in Fig. 6 by a white solid line.

For \(\overline{h}>0.5\), the diffusivity ratio \(D/D_0\) reaches a maximal value for a pillar density \(\phi _{\mathrm{max}}\) which can be calculated by deriving Eq. (12) relatively to \(\phi\) keeping \(\overline{h}\) constant. Such a calculation is performed numerically, and the solution is indicated in Fig. 6 by a white dashed line. Finally, the pillar aspect ratio \(\overline{h}_{\mathrm{max}}\) which maximizes the diffusivity ratio \(D/D_0\) for a given pillar density verifies

The solution of Eq. (18) is presented by a white dotted line in Fig. 6.

Rights and permissions

About this article

Cite this article

Darbois Texier, B., Laurent, P., Stoukatch, S. et al. Wicking through a confined micropillar array. Microfluid Nanofluid 20, 53 (2016). https://doi.org/10.1007/s10404-016-1724-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-016-1724-3