Abstract

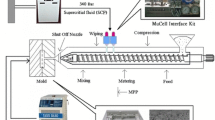

The properties of polyolefin nanocomposites strongly depend on the dispersion level of the nanoparticles, and the addition of dispersion agents has contributed to improvements in their performance. However, the mixing order of the components must be considered due to potential effects of each component alone. In this study, the morphology of the polypropylene nanocomposites was correlated to the preparation method, the use of hydrogenated hydrocarbon resin and the use of compatibilizing agents (PP-g-MA). The nanocomposites were prepared by intercalation of organoclay montmorillonite (OMMT) and PP-g-MA as compatibilizer with different maleic anhydride (MA) content in the molten state with either one-step or two-step mixing. A better distribution and dispersion of the OMMT platelets was achieved by using the two-step procedure. This improvement was observed to a significantly greater extent in samples with compatibilizing agents in the first mixing step. Additionally, the use of hydrogenated hydrocarbon resin showed improvement in morphology with lower MA content. These results point to the two-step method as a means to improve clay dispersion in the field of polyolefin nanocomposite processing.

Similar content being viewed by others

References

Kong J, Li Z, Cao Z, Han C, Dong L (2017) The excellent gas barrier properties and unique mechanical properties of poly (propylene carbonate)/organo-montmorillonite nanocomposites. Polym Bull 74(12):5065–5082

Dai X, Zhang Z, Chen C, Ding Q, Li M, Mai K (2017) Mechanical properties improvement of montmorillonite-filled isotactic polypropylene nanocomposites by β-modification. Polym Compos 38(S1):E412–E420

Santos K, Liberman S, Oviedo M, Mauler R (2008) Polyolefin-based nanocomposite: the effect of organoclay modifier. J Polym Sci Part B Polym Phys 46(23):2519–2531

Bettini S, Agnelli J (1999) Grafting of maleic anhydride onto polypropylene by reactive processing. I. Effect of maleic anhydride and peroxide concentrations on the reaction. J Appl Polym Sci 74(2):247–255

Dai X, Zhang Z, Wang C, Ding Q, Jiang J, Mai K (2013) Nucleation effect of montmorillonite with β-nucleating surface on polymorphous of melt-crystallized isotactic polypropylene nanocomposites. Compos Sci Technol 89:38–43

Kevadiya BD, Chettiar SS, Rajkumar S, Bajaj HC, Brahmbhatt H, Chaudhari JC, Thumbar RP, Jhala D, Rao MV (2014) Evaluation of montmorillonite/poly (L-lactide) microcomposite spheres as ambidextrous reservoirs for controlled release of capecitabine (xeloda) and assessment of cell cytotoxic and oxidative stress markers. Compos Sci Technol 90:193–201

Santos K, Castel CD, Liberman S, Oviedo M, Mauler R (2011) Polyolefin-based nanocomposite: the effects of processing aids. J Appl Polym Sci 119(3):1567–1575

Bischoff E, Daitx T, Simon DA, Schrekker HS, Liberman SA, Mauler RS (2015) Organosilane-functionalized halloysite for high performance halloysite/heterophasic ethylene–propylene copolymer nanocomposites. Appl Clay Sci 112:68–74

Istrate OM, Chen B (2014) Enhancements of clay exfoliation in polymer nanocomposites using a chemical blowing agent. Polym Int 63(12):2008–2016

Ton-That MT, Perrin-Sarazin F, Cole K, Bureau M, Denault J (2004) Polyolefin nanocomposites: formulation and development. Polym Eng Sci 44(7):1212–1219

Liborio P, Oliveira VA, Maria de Fatima VM (2015) New chemical treatment of bentonite for the preparation of polypropylene nanocomposites by melt intercalation. Appl Clay Sci 111:44–49

Rousseaux DDJ, Sclavons M, Godard P, Marchand-Brynaert J (2015) Polypropylene/clay nanocomposites: an innovative one-pot process. Polym Compos 36(4):644–650

Saffar A, Carreau PJ, Ajji A, Kamal MR (2014) Development of polypropylene microporous hydrophilic membranes by blending with PP-g-MA and PP-g-AA. J Membr Sci 462:50–61

Cimmino S, Duraccio D, Silvestre C, Pezzuto M (2009) Isotactic polypropylene modified with clay and hydrocarbon resin: compatibility, structure and morphology in dependence on crystallization conditions. Appl Surf Sci 256(3):S40–S45

Cimmino S, Silvestre C, Della Vecchia G (2004) Morphology and properties of isotactic polypropylene modified with hydrocarbon resin MBG273. I. Binary blends. J Appl Polym Sci 92(6):3454–3465

Cimmino S, Silvestre C, Duraccio D, Pezzuto M (2011) Effect of hydrocarbon resin on the morphology and mechanical properties of isotactic polypropylene/clay composites. J Appl Polym Sci 119(2):1135–1143

Silvestre C, Pezzuto M, Duraccio D, Mitchell GR, Cimmino S (2017) Quiescent and shear-induced non-isothermal crystallization of isotactic polypropylene-based nanocomposites. Polym Bull 74(1):145–165

Barbas J, Machado A, Covas J (2013) Evolution of dispersion along the extruder during the manufacture of polymer–organoclay nanocomposites. Chem Eng Sci 98:77–87

Bandyopadhyay J, Ray SS, Scriba M, Wesley-Smith J (2014) A combined experimental and theoretical approach to establish the relationship between shear force and clay platelet delamination in melt-processed polypropylene nanocomposites. Polymer 55(9):2233–2245

Hejazi I, Sharif F, Garmabi H (2011) Effect of material and processing parameters on mechanical properties of polypropylene/ethylene–propylene–diene–monomer/clay nanocomposites. Mater Des 32(7):3803–3809

Rust N, Ferg E, Masalova I (2006) A degradation study of isotactic virgin and recycled polypropylene used in lead acid battery casings. Polym Test 25(1):130–139

Canetti M, Scafati ST, Cacciamani A, Bertini F (2012) Influence of hydrogenated oligo (cyclopentadiene) on the structure and the thermal degradation of polypropylene-based nanocomposites. Polym Degrad Stab 97(1):81–87

Bischoff E, Simon D, Schrekker H, Lavorgna M, Ambrosio L, Liberman S, Mauler R (2016) Ionic liquid tailored interfaces in halloysite nanotube/heterophasic ethylene–propylene copolymer nanocomposites with enhanced mechanical properties. Eur Polym J 82:82–92

Bischoff E, dos Santos KS, Liberman SA, Mauler RS (2013) Estudo da dispersão de argilas organofílicas em nanocompósitos de prolipropileno obtidos pelo método em solução com auxílio de ultrassom. Polímeros 23(6):832–838

Wang D-Y, Leuteritz A, Kutlu B, Landwehr MAd, Jehnichen D, Wagenknecht U, Heinrich G (2011) Preparation and investigation of the combustion behavior of polypropylene/organomodified MgAl–LDH micro-nanocomposite. J Alloys Compd 509(8):3497–3501

Palacios J, Perera R, Rosales C, Albano C, Pastor JM (2012) Thermal degradation kinetics of PP/OMMT nanocomposites with mPE and EVA. Polym Degrad Stab 97(5):729–737

Qin H, Zhang S, Zhao C, Yang M (2005) Zero-order kinetics of the thermal degradation of polypropylene/clay nanocomposites. J Polym Sci Part B Polym Phys 43(24):3713–3719

Santos K, Bischoff E, Liberman S, Oviedo M, Mauler R (2011) The effects of ultrasound on organoclay dispersion in the PP matrix. Ultrason Sonochem 18(5):997–1001

Neto CP, Bischoff E, Santos KS, Oliveira RVB, Mauler RS (2018) The effects of styrenic oligomers on the thermomechanical properties of toughened polystyrene nanocomposites. Polym Bull 75(2):569–580

Zhu S, Chen J, Zuo Y, Li H, Cao Y (2011) Montmorillonite/polypropylene nanocomposites: mechanical properties, crystallization and rheological behaviors. Appl Clay Sci 52(1):171–178

Lu B, Chung T (1999) New maleic anhydride modified PP copolymers with block structure: synthesis and application in PP/polyamide reactive blends. Macromolecules 32(8):2525–2533

García-López D, Gobernado-Mitre I, Merino J, Pastor J (2007) Effect of the amount and funtionalization grade of PPgMA compatibilization agent in polypropylene/clay nanocomposites. Polym Bull 59(5):667–676

Garcıa-López D, Picazo O, Merino J, Pastor J (2003) Polypropylene–clay nanocomposites: effect of compatibilizing agents on clay dispersion. Eur Polym J 39(5):945–950

Bischoff E, Gonçalves G, Simon D, Schrekker H, Lavorgna M, Ambrosio L, Liberman S, Mauler R (2017) Unrevealing the effect of different dispersion agents on the properties of ethylene–propylene copolymer/halloysite nanocomposites. Mater Des 131:232–241

López-Quintanilla M, Sánchez-Valdés S, De Valle LR, Miranda RG (2006) Preparation and mechanical properties of PP/PP-g-MA/Org-MMT nanocomposites with different MA content. Polym Bull 57(3):385–393

Santos K, Liberman S, Oviedo M, Mauler R (2009) Optimization of the mechanical properties of polypropylene-based nanocomposite via the addition of a combination of organoclays. Compos A 40(8):1199–1209

Acknowledgements

The authors are grateful to CAPES, CNPq, Finep and FAPERGS/PRONEX for their financial support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Bischoff, E., Simon, D.A., Liberman, S.A. et al. Compounding sequence as a critical factor in the dispersion of OMMT/hydrocarbon resin/PP-g-MA/PP nanocomposites. Polym. Bull. 76, 849–863 (2019). https://doi.org/10.1007/s00289-018-2408-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-018-2408-9