Abstract

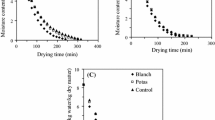

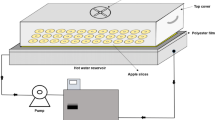

Onion slices were dried using two different drying techniques, convective and microwave drying. Convective drying treatments were carried out at different temperatures (50, 60 and 70 °C). Three different microwave output powers 328, 447 and 557 W were used in microwave drying. In convective drying, effective moisture diffusivity was estimated to be between 3.49 × 10−8 and 9.44 × 10−8 m2 s−1 within the temperature range studied. The effect of temperature on the diffusivity was described by the Arrhenius equation with an activation energy of 45.60 kJ mol−1. At increasing microwave power values, the effective moisture diffusivity values ranged from 2.59 × 10−7 and 5.08 × 10−8 m2 s−1. The activation energy for microwave drying of samples was calculated using an exponential expression based on Arrhenius equation. Among of the models proposed, Page’s model gave a better fit for all drying conditions used.

Similar content being viewed by others

Abbreviations

- a, b, c, n :

-

Constants of models

- D eff :

-

Effective diffusivity (m2 s−1)

- D 0 :

-

Pre-exponential factor of the Arrhenius equation (m2 s−1)

- E a :

-

Activation energy (kJ mol−1 or Wg−1)

- k :

-

Rate constants in models (min−1)

- k 0 :

-

Pre-exponential constant (min−1)

- L :

-

Thickness of the slab (m)

- m :

-

Raw of weight of sample (g)

- M:

-

Moisture content (kg water/kg dry matter)

- M e :

-

Equilibrium moisture content (kg water/kg dry matter)

- M 0 :

-

Initial moisture content (kg water/kg dry matter)

- MR:

-

Moisture ratio

- N :

-

Number of observations

- P :

-

Microwave output power (W)

- R 2 :

-

Determination coefficient

- RMSE:

-

Root mean square error

- T :

-

Temperature (°C)

- t :

-

Drying time (min)

- χ 2 :

-

Reduced Chi square

- z :

-

Number of constants in models

References

Ghanbarian D, Dastjerdi MB, Torki-Harchegani M (2016) Mass transfer characteristics of bisporus mushroom (Agaricus bisporus) slices during convective hot air drying. Heat Mass Trans 52:1081–1088

Feng H, Tang J (1998) Microwave finish drying of diced apples in a spouted bed. J Food Sci 63:679–683

Wang J, Xi YS (2005) Drying characteristics and drying quality of carrot using a two-stage microwave process. J Food Eng 68:505–511

Sharma GP, Prasad S (2004) Effective moisture diffusivity of garlic cloves undergoing microwave-convective drying. J Food Eng 65:609–617

Arslan D, Özcan MM (2010) Study the effect of sun, oven and microwave drying on quality of onion slices. LWT Food Sci Technol 43:1121–1127

Kumar DGP, Hebbar HU, Sukumar D, Ramesh MN (2005) Infrared and hot-air drying of onions. J Food Process Preserv 29:132–150

Vagenas GK, Karathanos VT (1993) Prediction of the effective moisture diffusivity in gelatinized food systems. J Food Eng 18:159–179

Toğrul İT, Pehlivan D (2004) Modelling of thin layer drying kinetics of some fruits under open-air sun drying process. J Food Eng 65:413–425

AOAC (1990) Official methods of analysis of the association of official analytical chemists (No. 934.06), Arlington

Ranganna S (2005) Hand book of analysis and quality control for fruits and vegetable products, 2nd edn. Tata McGraw Hill Book Co, New Delhi

Doymaz I (2006) Drying kinetics of black grapes treated with different solutions. J Food Eng 76:212–217

Demiray E, Tulek Y (2012) Thin-layer drying of tomato (Lycopersicum esculentum Mill. cv. Rio Grande) slices in a convective hot air dryer. Heat Mass Trans 48:841–847

Erbay Z, Icier F (2010) Thin-layer drying behaviors of olive leaves (Olea Europaea L.). J Food Process Eng 33:287–308

Akpinar EK (2006) Mathematical modelling of thin layer drying process under open sun of aromatic plants. J Food Eng 77:864–870

Tütüncü MA, Labuza T (1996) Effect of geometry on the effective moisture transfer diffusion coefficient. J Food Eng 30:433–447

Wang Z, Sun J, Liao X, Chen F, Zhao G, Wu J, Hu X (2007) Mathematical modeling on hot air drying of thin layer apple pomace. Food Res Int 40:39–46

Akpinar EK, Toraman S (2016) Determination of drying kinetics and convective heat transfer coefficients of ginger slices. Heat Mass Trans 52:2271–2281

Özbek B, Dadali G (2007) Thin-layer drying characteristics and modelling of mint leaves undergoing microwave treatment. J Food Eng 83:541–549

Demiray E, Tulek Y (2014) Drying characteristics of garlic (Allium sativum L.) slices in convective hot air dryer. Heat Mass Trans 50:779–786

Sarsavadia PN, Sawhney RL, Pangavhane DR, Singh SP (1999) Drying behaviour of brined onion slices. J Food Eng 40:219–226

Darıcı S, Şen S (2015) Experimental investigation of convective drying kinetics of kiwi under different conditions. Heat Mass Trans 51:1167–1176

Evin D (2011) Microwave drying and moisture diffusivity of white mulberry: experimental and mathematical modeling. J Mech Sci Technol 25:2711–2718

Toğrul H (2006) Suitable drying model for infrared drying of carrot. J Food Eng 77:610–619

Mota CL, Luciano C, Dias A, Barroca MJ, Guine RPF (2010) Convective drying of onion: kinetics and nutritional evaluation. Food Bioprod Process 88:115–123

Lewicki PP, Witrowa-Rajchert D, Nowak D (1998) Effect of drying mode on drying kinetics of onion. Dry Technol 16:59–81

Doymaz İ (2005) Drying characteristics and kinetics of okra. J Food Eng 69:275–279

Lin TM, Durance TD, Scaman CH (1998) Characterization of vacuum microwave, air and freeze dried carrot slices. Food Res Int 4:111–117

Dadalı G, Apar DK, Özbek B (2007) Microwave drying kinetics of okra. Dry Technol 25:917–924

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Demiray, E., Seker, A. & Tulek, Y. Drying kinetics of onion (Allium cepa L.) slices with convective and microwave drying. Heat Mass Transfer 53, 1817–1827 (2017). https://doi.org/10.1007/s00231-016-1943-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1943-x