Abstract

Background

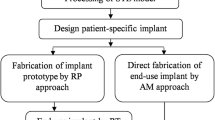

Rapid prototyping (RP) is used widely in dental and faciomaxillary surgery with anecdotal uses in orthopedics. The purview of RP in orthopedics is vast. However, there is no error analysis reported in the literature on bone models generated using office-based RP. This study evaluates the accuracy of fused deposition modeling (FDM) using standard tessellation language (STL) files and errors generated during the fabrication of bone models.

Materials and Methods

Nine dry bones were selected and were computed tomography (CT) scanned. STL files were procured from the CT scans and three-dimensional (3D) models of the bones were printed using our in-house FDM based 3D printer using Acrylonitrile Butadiene Styrene (ABS) filament. Measurements were made on the bone and 3D models according to data collection procedures for forensic skeletal material. Statistical analysis was performed to establish interobserver co-relation for measurements on dry bones and the 3D bone models. Statistical analysis was performed using SPSS version 13.0 software to analyze the collected data.

Results

The inter-observer reliability was established using intra-class coefficient for both the dry bones and the 3D models. The mean of absolute difference is 0.4 that is very minimal. The 3D models are comparable to the dry bones.

Conclusions

STL file dependent FDM using ABS material produces near-anatomical 3D models. The high 3D accuracy hold a promise in the clinical scenario for preoperative planning, mock surgery, and choice of implants and prostheses, especially in complicated acetabular trauma and complex hip surgeries.

Similar content being viewed by others

References

McGurk M, Amis AA, Potamianos P, Goodger NM. Rapid prototyping techniques for anatomical modelling in medicine. Ann R Coll Surg Engl 1997;79:169–74.

Webb PA. A review of rapid prototyping (RP) techniques in the medical and biomedical sector. J Med Eng Technol 2000;24:149–53.

Esses SJ, Berman P, Bloom AI, Sosna J. Clinical applications of physical 3D models derived from MDCT data and created by rapid prototyping. AJR Am J Roentgenol 2011;196:W683–8.

Torres K, Staskiewicz G, Sniezynski M, Drop A, Maciejewski R. Application of rapid prototyping techniques for modelling of anatomical structures in medical training and education. Folia Morphol (Warsz) 2011;70:1–4.

Melican MC, Zimmerman MC, Dhillon MS, Ponnambalam AR, Curodeau A, Parsons JR. Three-dimensional printing and porous metallic surfaces: A new orthopedic application. J Biomed Mater Res 2001;55:194–202.

Butscher A, Bohner M, Hofmann S, Gauckler L, Müller R. Structural and material approaches to bone tissue engineering in powder-based three-dimensional printing. Acta Biomater 2011;7:907–20.

Ciocca L, De Crescenzio F, Fantini M, Scotti R. CAD/CAM and rapid prototyped scaffold construction for bone regenerative medicine and surgical transfer of virtual planning: A pilot study. Comput Med Imaging Graph 2009;33:58–62.

Leukers B, Gülkan H, Irsen SH, Milz S, Tille C, Schieker M, et al. Hydroxyapatite scaffolds for bone tissue engineering made by 3D printing. J Mater Sci Mater Med 2005;16:1121–4.

Seitz H, Rieder W, Irsen S, Leukers B, Tille C. Three-dimensional printing of porous ceramic scaffolds for bone tissue engineering. J Biomed Mater Res B Appl Biomater 2005;74:782–8.

Mankovich NJ, Cheeseman AM, Stoker NG. The display of three-dimensional anatomy with stereolithographic models. J Digit Imaging 1990;3:200–3.

Tonner HD, Engelbrecht H. A new method for the preparation of special alloplastic implants for the partial replacement of the pelvis. Fortschr Med 1979;97:781–3.

Metzger MC, Hohlweg-Majert B, Schwarz U, Teschner M, Hammer B, Schmelzeisen R. Manufacturing splints for orthognathic surgery using a three-dimensional printer. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 2008;105:e1–7.

Goiato MC, Santos MR, Pesqueira AA, Moreno A, dos Santos DM, Haddad MF. Prototyping for surgical and prosthetic treatment. J Craniofac Surg 2011;22:914–7.

Schwartz A, Money K, Spangehl M, Hattrup S, Claridge RJ, Beauchamp C. Office-based rapid prototyping in orthopedic surgery: A novel planning technique and review of the literature. Am J Orthop (Belle Mead NJ) 2015;44:19–25.

Minns RJ, Bibb R, Banks R, Sutton RA. The use of a reconstructed three-dimensional solid model from CT to aid the surgical management of a total knee arthroplasty: A case study. Med Eng Phys 2003;25:523–6.

Munjal S, Leopold SS, Kornreich D, Shott S, Finn HA. CT-generated 3-dimensional models for complex acetabular reconstruction. J Arthroplasty 2000;15:644–53.

Fu M, Lin L, Kong X, Zhao W, Tang L, Li J, et al. Construction and accuracy assessment of patient-specific biocompatible drill template for cervical anterior transpedicular screw (ATPS) insertion: An in vitro study. PLoS One 2013;8:e53580.

Debarre E, Hivart P, Baranski D, Déprez P. Speedy skeletal prototype production to help diagnosis in orthopaedic and trauma surgery. Methodology and examples of clinical applications. Orthop Traumatol Surg Res 2012;98:597–602.

Krishnan SP, Dawood A, Richards R, Henckel J, Hart AJ. A review of rapid prototyped surgical guides for patient-specific total knee replacement. J Bone Joint Surg Br 2012;94:1457–61.

L-30029-02.

Windisch G, Salaberger D, Rosmarin W, Kastner J, Exner GU, Haldi-Brändle V, et al. A model for clubfoot based on micro-CT data. J Anat 2007;210:761–6.

Guarino J, Tennyson S, McCain G, Bond L, Shea K, King H. Rapid prototyping technology for surgeries of the pediatric spine and pelvis: Benefits analysis. J Pediatr Orthop 2007;27:955–60.

Dawood A, Marti BM, Jackson VS, Darwood A. 3D printing in dentistry. Br Dent J 2015;219:521–9.

Moore-Jansen PH, Ousely SD, Jantz RL. Data Collection Procedures for Forensic Skeletal Material. 3rd ed. Knoxville, Tennessee: University of Tennessee Forensic Anthropology Series; 1994.

Parhate VG. Techno-economic and error analysis of rapid prototyping patterns. IJITR 2014;2:1003–11.

Peng AH. Principle of error analysis for rapid prototyping technology. Appl Mech Mater 2012;121–6:330–4.

Luo N, Wang Q. Fast slicing orientation determining and optimizing algorithm for least volumetric error in rapid prototyping. Int J Adv Manuf Technol 2016;83:1297–313.

Sun H, Li B, Zhao Z, Zhang L, Shen SG, Wang X. Error analysis of a CAD/CAM method for unidirectional mandibular distraction osteogenesis in the treatment of hemifacial microsomia. Br J Oral Maxillofac Surg 2013;51:892–7.

Nizam A, Gopal RN, Naing L, Hakim AB, Samsudin AR. Dimensional accuracy of the skull models produced by rapid prototyping technology using stereolithography apparatus. Arch Orofac Sci 2006;1:60–6.

El-Katatny I, Masood SH, Morsi YS. Error analysis of FDM fabricated medical replicas. Rapid Prototyp J 2010;16:36–43.

Dhakshyani R, Nukman Y, Noor Azuan AO. FDM models and FEA in dysplastic hip. Rapid Prototyp J 2012;18:215–21.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Reddy, M.V., Eachempati, K., Gurava Reddy, A.V. et al. Error Analysis: How Precise is Fused Deposition Modeling in Fabrication of Bone Models in Comparison to the Parent Bones?. IJOO 52, 196–201 (2018). https://doi.org/10.4103/ortho.IJOrtho_312_16

Published:

Issue Date:

DOI: https://doi.org/10.4103/ortho.IJOrtho_312_16