Abstract

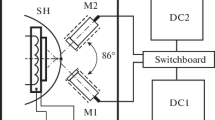

The residual stress in beryllium films fabricated on K9 substrates by using magnetron sputtering deposition is measured by using a curvature method and is theoretically estimated by using the Nix and Clemens (NC) model. The experimental results indicate that the 1.3-μm-thick film is always in a tensile state for pressure variations in the range from 0.4 to 1.2 Pa. When the sputtering gas pressure is increased, the average stress increases at first, after which it decreases by a remarkable amount. The observed descending trend of the tensile stress when the sputtering gas pressure is beyond 0.6 Pa is mainly attributed to the grain size in the film being larger than that in the film when the pressure is below 0.6 Pa. The maximal residual stress of 552 MPa at a sputtering gas pressure of 0.6 Pa is close to the tensile strength (550 MPa) of the corresponding beryllium bulk material and is about 8 times smaller than that calculated by using the N-C model. In addition, the surface morphologies of the as-fabricated films reveal fibrous grains while the cross-sectional morphologies are characterized by a coarsening of columnar grains. The measured electric resistivity of each film strongly depends on its porosity and the sizes of its grains.

Similar content being viewed by others

References

H. W. Xu et al., Fusion Sci. Tech. 51, 547 (2007).

S. W. Haan, D. A. Callahan and M. J. Edwards, Fusion Sci. Tech. 55, 228 (2009).

A. J. Detor, A. M. Hodge, E. Chason, Y. M. Wang, H. W. Xu, M. Conyers, A. Nikroo and A. Hamz, Acta Mater. 57, 2055 (2009).

J. A. Thornton and D. W. Hoffman, Thin solid films 171, 5 (1989).

W. D. Nix and B. M. Clemens, J. Mater. Res. 14, 3467 (1999).

N. H. Kim, C. II. Park and H. Y. Lee, J. Korean Phys. Soc. 63, 229 (2013).

S. C. Seel and C. V. Thompson, J. Appl. Phys. 93, 9038 (2003).

H. W. Xu et al., J. Mater. Res. 27, 822 (2012).

H. P. Wang, J. Chang and B. Wei, J. Appl. Phys. 106, 033506 (2009).

X. B. Ma, H. P. Wang, K. Zhou, J. Chang and Z. Y. Hong, Appl. Phys. Lett. 103, 104101 (2013).

Y. Tsuda, H. Omoto, K. Tanaka and H. Ohsaki, Thin Solid Films 502, 223 (2006).

Y. C. Yang, C. H. Tsaua and J. W. Yeh, Scripta Mater. 64, 173 (2011).

F. A. Doljack and R. W. Hoffman, Thin Solid Films 12, 71 (1972).

G. G. Stoney, Proc. Roy. Soc., London Set. A 82, 172 (1909).

C. A. Klein, J. Appl. Phys. 88, 5487 (2000).

D. K. Kim and H. B. Kim. J. Korean Phys. Soc. 66, 1581 (2015)

H. B. Xie, Vacuum 3, 37 (1999).

B. C. Luo, K. Li, X. L. Kang, J. Q. Zhang, Y. D. He, J. S. Luo, W. D. Wu and Y. J. Tang, Chin. Phys. B 23, 066804 (2014).

F. Mammoliti, M. G. Grimal and F. La Via, J. Appl. Phys. 92, 3147 (2002).

L. He, Z. Y. Ling, J. Appl. Phys. 110, 093708 (2011).

A. F. Mayadas and M. Shatzkes, Phys. Rev. B1 13, 82 (1970).

E. H. Sondheimer, Adv. in Phys. 1, 1 (1952).

J. W. Lim, K. Mimura and M. Isshiki, Appl. Surf. Sci. 217, 95 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, BC., Li, K., Zhang, JQ. et al. Effect of argon gas pressure on residual stress, microstructure evolution and electrical resistivity of beryllium films. Journal of the Korean Physical Society 68, 557–562 (2016). https://doi.org/10.3938/jkps.68.557

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.68.557