Abstract

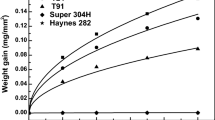

The influence of the corrosive environment on strength characteristics of heat-resistant alloys at high temperatures is discussed. The results of corrosion tests for two heat-resistant nickelbased alloys simulating the processes of alloy sulfide-oxide corrosion during operation are presented. Extrapolated values of specific mass changes for 5000 h at temperatures of 600–750 °C were determined using the mathematical models obtained for tests lasted up to 1000 h.

Similar content being viewed by others

References

Getsov, L.B., Materialy i prochnost’ detalei gazovykh turbin (Materials and Strength of Gas Turbine Parts), Rybinsk: Gazoturbinnye Tekhnologii, 2010, vol. 1.

Nikitin, V.I., Korroziya i zashchita lopatok gazovykh turbin (Corrosion and Protection of Gas Turbine Blades), Leningrad: Mashinostroenie, 1987.

Inozemtsev, A.A., Nikhamkin, M.A., and Sandratskii, V.L., Osnovy konstruirovaniya aviatsionnykh dvigatelei i energeticheskikh ustanovok (Basics of Designing Aircraft Engines and Power Plants), Moscow: Mashinostroenie, 2008, vol. 2, Compressors. Combustion Chambers. Afterburner Cameras. Turbines. Outlet Devices.

Kablov, E.N., Ospennikova, O.G., and Lomberg, B.S., Strategic Directions of Development of Structural Materials and Technologies for Their Processing for Engines of the Present and the Future, Avtomaticheskaya Svarka, 2013, nos. 10–11, pp. 23–32.

Kablov, E.N. Strategic Directions of Developing Materials and Their Processing Technologies for the Period up to 2030, Aviatsionnye Materialy i Tekhnologii, 2012, no. S, pp. 7–17.

Kablov, E.N., Innovative Development of FSUE “VIAM” SSC RF on Implementation of “Strategic Directions of Developing Materials and Their Processing Technologies for the Period up to 2030”, Aviatsionnye Materialy i Tekhnologii, 2015, no. 1 (34), pp. 3–33.

Inozemtsev, A.A., Avgustinovich, V.G., and Tsatiashvili, V.V., Prediction of Emission Characteristics Using the Reactor Model of Combustion Chamber, Izv. Vuz. Av. Tekhnika, 2011, vol. 54, no. 1, pp. 45–50 [Russian Aeronautics (Engl. Transl.), vol. 54, no. 1, pp. 62–70].

Kablov, E.N., Sidorov, V.V., Kablov, D.E., and Min, P.G., The Metallurgical Fundamentals for High Quality Maintenance of Single Crystal Heat-Resistant Nickel Alloys, Aviatsionnye Materialy i Tekhnologii, 2017, no. 5, pp. 55–71.

Grinevich, A.V., Laptev, A.B., Skripachev, S.Yu., and Nuzhnyi, G.A., Matrix of Strength Characteristics for Estimation of Limit States of Structural Metallic Materials, Aviatsionnye Materialy i Tekhnologii, 2018, no. 2 (51), pp. 67–74.

Inozemtsev, A.A., Andreichenko, I.L., and Dvoinikov, S.S., Topical Issues on the Development of a Methodology for Specifying the Corrosion Life of Gas Turbine Engines and Gas Turbine Plants, Doklady vserossiiskoi nauchno-tekhnicheskoi konf. “Problemy otsenki klimaticheskoi stoikosti materialov i slozhnykh tekhnicheskikh system” (Proc. of the All-Russian Scientific and Technical Conference “Problems of Assessing the Climatic Resistance of Materials and Complex Technical Systems”), Gelendzhik, 2013, Moscow: VIAM, pp. 33–46.

Petrenya, Yu.K., Nikitin, V.I., and Rybnikov, A.I., Sulfide-Oxide Corrosion of Materials and Coatings of Gas Turbine Blades, Trudy TsKTI, 2006, issue 295, pp. 26–42.

Getsov, L.B., Madorskii, A.Ya., Mozzhukhina, N.N., Tereshchenko, A.G., and Yushchenkov, E.E., Effect of Ash Deposits on the Heat Resistance of Materials of GTE Blades, Problemy Prochnosti, 1989, no. 1, pp. 71–76.

Laptev, A.B, Nikolaev, E.V., and Pavlov, M.R., Research of Causes of the 06Kh16N15M2G2TFR Steel Destruction of the Furnace Coil and the Development of the Protection Method, Praktika Protivokorrozionnoi Zashchity, 2017, no. 1 (83), pp. 39–44.

Getsov, L.B., Rybnikov, A.I., Krukovski, P.G., and Kartavova, E.S., De-Alloying and Fatigue of High Temperature Alloys Used for Gas Turbine Blades, Materials at High Temperatures, 1995, vol. 13, no. 2, pp. 81–86.

Danilov, D.V., Development of a High-Heat Resistant Nickel Alloy with Improved Corrosion Resistance under the Marine Salt Environment Conditions for Single-Crystal GTE Blades, Cand. Sc. (Tech.) Dissertation, Rybinsk, RGATU, 2015.

Petrushin, N.V., Ospennikova, O.G., and Svetlov, I.L., Single-Crystal Heat-Resistant Nickel Alloys for Turbine Blades of Advanced Gas Turbine Engines, Aviatsionnye Materialy i Tekhnologii, 2017, no. 5, pp. 72–103.

GOST (State Standard) R 52802-2007, Pelletized Nickel-Base Superalloys. Grades, 2008.

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian Text © The Author(s), 2019, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Aviatsionnaya Tekhnika, 2019, No. 4, pp. 150–155.

About this article

Cite this article

Getsov, L.B., Laptev, A.B., Puzanov, A.I. et al. Sulfide Oxide Corrosion of Modern Heat-Resistant Alloys. Russ. Aeronaut. 62, 689–695 (2019). https://doi.org/10.3103/S1068799819040214

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068799819040214