Abstract

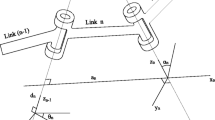

The article continues description of geometric errors laser correction for multi-axis NC-systems–CMMs and machine-tools. The Kalman’s concept of observability and controllability is applied to the method. In order to observe the multi-axis system a versatile laser measuring system is used, and in order to control the system a program postprocessor is proposed, introduced between CAD/CAM and NC-systems.

Similar content being viewed by others

References

Grigoriev, S.N., Masterenko, D.A., Teleshevsky, V.I., and Emelyanov, P.N., Contemporary state and outlook for development of metrological assurance in the machine-building industry, Meas. Tech., 2013, vol. 55, no. 11, pp. 1311–1315.

Teleshevsky, V.I. and Grishin, S.G., Measuring information system for nanometrology, Vestn. Mosk. Gos. Tekhnol. Univ., Stankin, 2008, no. 2, pp. 33–40.

Teleshevsky, V.I. and Sokolov, V.A., Laser measuring information system to improve the precision of multiaxis CNC machines, Vestn. Mosk. Gos. Tekhnol. Univ., Stankin, 2011, no. 4, pp. 8–10.

Grigoriev, S.N. and Teleshevsky, V.I., Measurement problems in technological shaping processes, Meas. Tech., 2011, vol. 54, no. 7, pp. 744–749.

Teleshevsky, V.I., Grigoriev, S.N., Andreev, A.G., Kolner, L.S., and Osipov, P.A., Engineering of precision machines for nanometer production, Vestn. Mosk. Gos. Tekhnol. Univ., Stankin, 2015, no. 3 (34), pp. 9–14.

Petrov, P.S., Feofanov, A.N., and Rybakov, A.V., Compilation of database for development of universal-modular accessories for CNC machines, Vestn. Mosk. Gos. Tekhnol. Univ., Stankin, 2016, no. 1 (36), pp. 17–20.

McKeown, P.A. and Loxham, J., Some aspects of the design of high precision measuring machines, Ann. CIRP, 1973, vol. 22, no. 1.

Schwenke, H., Geometric error management and compensation of machines—an update, Ann. CIRP, 2008, vol. 57, pp. 660–675.

Grigoriev, S.N., Teleshevsky, V.I., and Sokolov, V.A., Volumetric geometric accuracy improvement for multiaxis systems based on laser software error correction, Int. Conf. on Competitive Manufacturing “COMA’13,” January 30—February 1, 2013, Stellenbosch, 2013, pp. 301–306.

Teleshevsky, V.I. and Sokolov, V.A., Laser correction of geometric errors of multi-axis programmed-controlled systems, Meas. Tech., 2012, vol. 55, no. 5, pp. 535–541.

Renishaw Company, System for precision measurement and process control. http://renishaw.com. Accessed April 21, 2016.

Voronov, A.A., Vvedenie v dinamiku slozhnykh upravlyaemykh sistem (Introduction into Dynamics of Complex Control Systems), Moscow: Nauka, 1985.

Teleshevsky, V.I., Measuring informatics in mechanical engineering, Vestn. Mosk. Gos. Tekhnol. Univ., Stankin, 2008, no. 1, pp. 33–38.

Puchkov, V.P., Skhirtladze, A.G., Evart, T.E., and Prise, N.M., Numerical analysis of precise operations of CNC machines, Vestn. Mosk. Gos. Tekhnol. Univ., Stankin, 2015, no. 2 (33), pp. 68–72.

Teleshevsky, V.I., Grigoriev, S.N., Andreev, A.G., et al., Metrological certification of laser microscopes based on the modulation interferometry with controlled phase shift, Vestn. Mosk. Gos. Tekhnol. Univ., Stankin, 2015, no. 3 (34), pp. 67–75.

Serkov, N.A., Tochnost’ mnogokoordinatnykh mashin s ChPU: teoreticheskie i eksperimental’nye osnovy (Precision of Multi-Axis CNC Machines: Theoretical and Experimental Principles), Moscow: Lenand, 2015.

Sabirov, F.S., Proizvoditel’nost’ i tochnost’ v rabochem prostranstve stanka (Efficiency and Precision of the Machine), Moscow: Mosk. Gos. Tekh. Univ., Stankin, 2012.

Okafor, A.C. and Ertekin, Y.M., Derivation of machine tool error models and error compensation procedure for three axes vertical machining center using rigid body kinematics, Int. J. Mach. Tools Manuf., 2000, no. 40 (8), pp. 1199–1213.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.I. Teleshevsky, P.N. Emelyanov, V.A. Sokolov, 2016, published in STIN, 2016, No. 9, pp. 14–19.

The article was translated by the authors.

About this article

Cite this article

Teleshevsky, V.I., Emelyanov, P.N. & Sokolov, V.A. Software correction of volumetric geometrical errors of multi-axis systems based on laser interferometric measurements. Russ. Engin. Res. 37, 248–252 (2017). https://doi.org/10.3103/S1068798X17030194

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X17030194