Abstract

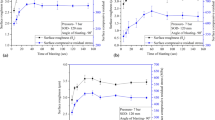

The physics of grinding is considered in order to explain the difference in machinability of tungstenfree and tungsten steels. The strength of the most common steels and alloys is studied over a broad range of strain rate and temperature. Analysis of the results established the variation in strength of high-speed tungsten-free and tungsten steels in typical grinding conditions and permits explanation of the difference in machinability of the steels in physical terms. The relation between the machinability of steel and wear of the abrasive tool is investigated in experiments with individual grains (plane angle ϕ = 90°) of different abrasive materials: electrocorundum (24A), zirconium corundum (38A), and Elbor (Borazon). That permits the derivation of a regression equation reflecting the qualitative characteristics of the process, such as the starting point, the presence of an extremum, and the asymptotic behavior.

Similar content being viewed by others

References

Gordeev, A.V. and Vostroknutov, D.V., Grinding of chip grooves in the axial cutting tool of tungsten free fast cutting steels, Metalloobrabotka, 2004, no. 6, pp. 2–6.

D’yakonov, A.A., The theory of material treatment during implementation of abrasives. Part 1: Definition and formal description, Vestn. Yuzh.-Ural. Gos. Univ., Ser. Mashinostr., 2015, vol. 15, no. 1, pp. 54–68.

Korchak, S.N., Proizvoditel’nost’ protsessa shlifovaniya stal’nykh detalei (Efficiency of the Grinding of Steel Parts), Moscow: Mashinostroenie, 1974.

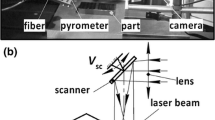

Koshin, A.A., Klochko, V.I., Akanovich, V.A., and Butorin, G.I., The direct measurement of integral parameters of high-speed interrupted grinding, in Vses. nauchno-tekhn. konf. “Covremennoe sostoyanie i perspektivy vysokoskorostnoi fotografii i metrologii bystroprotekayushchikh protsessov,” Tezisy dokladov (All-Union Sci.-Tech. Conf. “Modern Status and Prospects of the High-Speed Photography and Metrology of Rapid Processes,” Abstracts of Papers), Moscow: Vseross. Nauchno-Issled. Inst. Opt.-Fiz. Izmer., 1975, p. 53.

D’yakonov, A.A., Blank-cutter interaction in highspeed cutting, Russ. Eng. Res., 2014, vol. 34, no. 12, pp. 775–777.

Ardashev, D.V., The mechanical wear of abrasive grains at grinding, Vestn. Yuzh.-Ural. Gos. Univ., Ser. Mashinostr., 2014, no. 4, pp. 55–65.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.A. D’yakonov, 2015, published in STIN, 2015, No. 6, pp. 27–30.

About this article

Cite this article

D’yakonov, A.A. Abrasive-tool wear and the machinability of high-speed tungsten-free steels. Russ. Engin. Res. 36, 67–70 (2016). https://doi.org/10.3103/S1068798X1601010X

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X1601010X