Abstract—

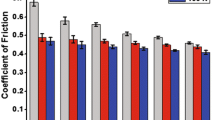

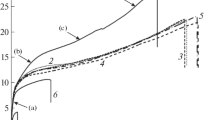

This paper presents the results of a study of polymer composite materials based on ultra-high molecular weight polyethylene (UHMWPE) modified with a borpolymer (BP). It has been established that the introduction of a BP into a polymer matrix affects the tribological properties. Thus, the wear resistance of composites with a content of 3–5 wt % BP increased by 2.4–6.0 times compared with the initial UHMWPE. The coefficient of friction of composites at a content of 0.2–3.0 wt % BP remains at the level of the initial UHMWPE. When the content is 5 wt % BP in the composite this leads to a decrease in the coefficient of friction by 25% relative to the original polymer. It was found that the introduction of BP into the polymer matrix increases the wear resistance by 6 times and reduces the friction coefficient by 25% relative to the initial UHMWPE. It is shown that with an increase in the BP content in the polymer matrix during tribocontact, a structural rearrangement of the surface layers occurs with the formation of a secondary structure. It has been established that at a low content of BP, the adhesive friction prevails, which is confirmed by the presence of sagging and protrusions on the friction surface. A study of the morphology of the friction surface showed that the formation of secondary structures results in smoothing the grooves. This indicates a decrease in the abrasive action of the steel counterbody on the polymer, which leads to a decrease in the friction coefficient. The research results can be used in the development of composite materials based on UHMWPE for tribological purposes, used for friction units of machinery and process equipment as plain bearings and sealing washers due to the low friction coefficient and the absence of abrasive action.

Similar content being viewed by others

REFERENCES

Kurtz, S.M., UHMWPE Biomaterials Handbook: Ultra-High Molecular Weight Polyethylene in Total Joint Replacement and Medical Devices, Amsterdam: Elsevier, 2009.

Panin, S., Kornienko, L., Thuc, N.X., Ivanova, L.R., and Shilko, S.V., The role of micro- and nanofillers in abrasive wear of composites-based on ultra-high molecular weight polyethylene, Adv. Mater. Res., 2014, vol. 1040, pp. 148–154.

Abdul Samad, M., Recent advances in UHMWPE/ UHMWPE nanocomposite/UHMWPE hybrid nanocomposite polymer coatings for tribological applications: a comprehensive review, Polymers, 2021, vol. 13, no. 4, p. 608.

Danilova, S.N., Yarusova, S.B., Kulchin, Y.N., Zhevtun, I.G., Buravlev, I.Y., Okhlopkova, A.A., Gordienko, P.S., and Subbotin, E.P., UHMWPE/CaSiO3 nanocomposite: mechanical and tribological properties, Polymers, 2021, vol. 13, no. 4, p. 570.

Korabel’nikov, D.V., Lenskii, M.A., Ozhogin, A.V., Gorbunov, A.V., Kel’m, R.R., Vashurin, I.V., and Skutaru, I.A., Formation of interpenetrating three-dimensional nets in composite materials containing rubber modified with the addition of polymethylene-p-triphenyl ether of boric acid, Polzunovskii Vestn., 2015, vol. 1, no. 4-1, pp. 154–157.

Tarasevich, B.N., IK spektry osnovnykh klassov organicheskikh soedinenii (IR Spectra of the Main Classes of Organic Compounds), Moscow: Mosk. Gos. Univ., 2012.

Mashkov, Yu.K., Tribofizika metallov i polimerov: monografiya (Tribophysics of Metals and Polymers: Monograph), Omsk: Omsk. Gos. Tekhn. Univ., 2013.

Wang, J., Yan, F., and Xue, Q., Friction and wear behavior of ultra-high molecular weight polyethylene sliding against GCr15 steel and electroless Ni–P alloy coating under the lubrication of seawater, Tribol. Lett., 2009, vol. 35, no. 2, pp. 85–95.

Zum Gahr, K.-H., Microstructure and Wear of Materials, Amsterdam: Elsevier, 1987.

Bochkareva, S.A., Panin, S.V., Lyukshin, B.A., Lyukshin, P.A., Grishaeva, N.Yu., Matolygina, N.Yu., and Aleksenko, V.O., Simulation of frictional wear with account of temperature for polymer composites, Phys. Mesomech., 2020, vol. 23, no. 2, pp. 147–159.

Korneev, A.A., Lyubimova, A.S., and Shilov, N.V., The influence of surface roughness on the strength of a joint obtained using metal-polymer composite materials, Elektrotekh. Inf. Kompl. Sist., 2012, vol. 8, no. 2, p. 3.

Funding

The authors would like to acknowledge Ministry of Science and Higher Education of the Russian Federation (Grant no. FSRG-2020-0017).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Okhlopkova, A.A., Danilova, S.N., Dyakonov, A.A. et al. Tribological Properties of Composites Based on a UHMWPE Modified Borpolymer. J. Frict. Wear 43, 27–34 (2022). https://doi.org/10.3103/S1068366622010081

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366622010081