Abstract

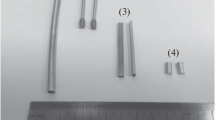

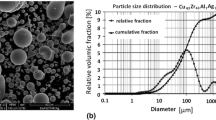

This paper provides the first part of a study on the effect of magnesium on the structural phase composition and physical and mechanical properties of nanostructured aluminum–magnesium composite materials with the composition AlxMgy + 0.3 wt % C60 fullerene. Composite powders are obtained by the simultaneous mechanical activation of the initial materials in a planetary ball mill in an argon atmosphere. It is found that the powders have a complex hierarchical structure made up of 50–200 μm aggregates consisting of 5–10 μm strong high-density agglomerates, which in turn are a combination of nanoscale (30–60 nm) crystallites. It is found that the increase in magnesium concentration in the composite up to 18 wt % makes it possible to obtain crystallites with an average size of less than 30 nm during mechanical activation, while the size of aggregates is less than 50 μm. The maximum solubility of magnesium in aluminum with a crystallite size of 30–70 nm during mechanical activation is 15 wt % (17 at %). Using the differential scanning calorimetry method, it is found that nanostructured composites undergo irreversible structural phase transformations during heat treatment in a temperature range of 250–400°C: recrystallization, decomposition of the α-solid solution of magnesium in aluminum, and the formation of intermetallic β-(Al3Mg2), γ-(Al12Mg17) and carbide (Al4C3) phases. In addition, the Raman spectra contain peaks that, according to some sources, correspond to covalent compounds of aluminum with C60 fullerene—aluminum–fullerene complexes. The data that have been obtained will be used in further research to determine the parameters for the thermobaric treatment of nanocomposite powder mixtures in order to obtain and test bulk samples.

Similar content being viewed by others

REFERENCES

Estrin, Y., Murashkin, M., and Valiev, R., Ultrafine-grained aluminium alloys: processes, structural features and properties, in Fundamentals of Aluminium Metallurgy, Woodhead Publ., 2011, pp. 468–503.

Lloyd, D.J., Particle reinforced aluminium and magnesium matrix composites, Int. Mater. Rev., 1994, vol. 39, no. 1, pp. 1–23.

Markushev, M.V., Bampton, C.C., Murashkin, M.Yu., and Hardwick, D.A., Structure and properties of ultra-fine grained aluminium alloys produced by severe plastic deformation, Mater. Sci. Eng., A, 1997, vols. 234–236, pp. 927–931.

Murashkin, M.Yu., Kil’mametov, A.R., and Valiev, R.Z., Structure and mechanical properties of an aluminum alloy 1570 subjected to severe plastic deformation by high-pressure torsion, Phys. Met. Metallogr., 2008, vol. 106, no. 1, pp. 90–96.

Popov, M., Medvedev, V., Blank, V., Denisov, V., Kirichenko, A., Tat’yanin, E., and Zaitsev, V., Fulleride of aluminum nanoclusters, J. Appl. Phys., 2010, vol. 108, no. 9, pp. 094 317-1–094 317-6.

Evdokimov, I.A., Perfilov, S.A., Pozdnyakov, A.A., Blank, V.D., Bagramov, R.Kh., Perezhogin, I.A., Kulnitsky, B.A., Kirichenko, A.N., and Aksenenkov, V.V., Nanostructured composite materials based on Al–Mg alloy modified with fullerene C60, Inorg. Mater.: Appl. Res., 2018, vol. 9, no. 3. pp. 472–477.

Choi, K., Shin, S., Bae, D., and Choi, H., Mechanical properties of aluminum-based nanocomposite reinforced with fullerenes, Trans. Nonferrous Met. Soc. China, 2014, vol. 24, pp. 47–52.

Mal’tseva, T.V., Ozerets, N.N., Levina, A.V., and Ishina, E.A., Tsvetnye metally i splavy. Uchebnoe posobie (Nonferrous Metals and Alloys. Student’s Book), Yekaterinburg: Ural, 2019.

Starink, M.J. and Zahra, A.M., β' and β precipitation in an Al–Mg alloy studied by DSC and TEM, Acta Mater., 1998, vol. 46, no. 10, pp. 3381–3397.

Siyuan, L., Fusheng, P., Kainer, K.U., Yafang, H., and Wei, K., Progress in Light Metals, Aerospace Materials and Superconductors, Trans Tech Publ., 2007.

Mukai, T., Higashi, K., and Tanimura, S., Influence of the magnesium concentration on the relationship between fracture mechanism and strain rate in high purity Al–Mg alloys, Mater. Sci. Eng., A, 1994, vol. 176, nos. 1–2, pp. 181–189.

Schoenitz, M. and Dreizin, E.L., Structure and properties of Al–Mg mechanical alloys, J. Mater. Res., 2003, vol. 18, no. 08, pp. 1827–1836.

Jie, J.C., Zou, C.M., Wang, H.W., Li, B., and Wei, Z.J., Mechanical properties of Al(Mg) solid solution prepared by solidification under high pressures, J. Alloys Compd., 2012, vol. 510, no. 1, pp. 11–14.

Scudino, S., Sakaliyska, M., Surreddi, K.B., and Eckert, J., Mechanical alloying and milling of Al–Mg alloys, J. Alloys Compd., 2009, vol. 483, nos. 1–2, pp. 2–7.

Calka, A., Kaczmarek, W., and Williams, J.S., Extended solid solubility in ball-milled Al–Mg alloys, J. Mater. Sci., 1993, vol. 28, pp. 15–18.

Al-Aqeeli, N., Mendoza-Suarez, G., and Drew, R.A.L., XRD and TEM characterization of Al–Mg-based nanocomposite alloys, Rev. Adv. Mater. Sci., 2008, vol. 18, pp. 231–235.

Evdokimov, I.A., Khayrullin, R.R., Perfilov, S.A., Pozdnyakov, A.A., Bagramov, R.H., Perezhogin, I.A., and Blank, V.D., Nanostructured aluminum matrix composite materials, modified by carbon nanostructures, Mater. Today: Proc., 2018, vol. 5, no. 12, pp. 26 153–26 159.

Aborkin, A.V., Evdokimov, I.A., Vaganov, V.E., Alymov, M.I., Abramov, D.V., and Khor’kov, K.S., Influence of mechanical activation mode on morphology and phase composition of Al–2Mg–nC nanostructured composite material, Nanotechnol. Russ., 2016, vol. 11, pp. 297–304.

Gryaznov, V.G., Kaprelov, A.M., and Romanov, A.E., Size effects of dislocation stability in small particles and microcrystallities, Scr. Metall., 1989, vol. 23, pp. 1443–1448.

Rabinovich, M.K., Markushev, M.V., and Murashkin, M.Yu., Special features of formation of the submicrocrystalline structure in strain-heat treatment of aluminum alloy 1420 in different initial states, Met. Sci. Heat Treat., 1997, vol. 39, no. 4, pp. 172–176.

Lapovok, R., Timokhina, I., McKenzie, P.W.J., and O’Donnell, R., Processing and properties of ultrafine-grain aluminium alloy 6111 sheet, J. Mater. Process. Technol., 2008, vol. 200, nos. 1–3, pp. 441–450.

Totten, G.E. and MacKenzie, D.S., Handbook of Aluminum, vol. 1: Physical Metallurgy and Processes, Marcel Dekker, 2003.

Funding

This research was funded by the Ministry of Science and Higher Education of the Russian Federation as part of Grant Agreement no. 075-15-2019-1307 (no. 14.574.21.0162) dated June 14, 2019, agreement identifier RFMEFI57417X0162.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Sh. Galyaltdinov

About this article

Cite this article

Evdokimov, I.A., Khayrullin, R.R., Bagramov, R.K. et al. Nanostructured Strain-Hardened Aluminum–Magnesium Alloys Modified by C60 Fullerene Obtained by Powder Metallurgy: Part 1. The Effect of the Magnesium Concentration on the Structure and Phase Composition of Powders. Russ. J. Non-ferrous Metals 62, 132–137 (2021). https://doi.org/10.3103/S1067821221010089

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821221010089