Abstract

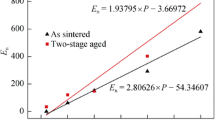

Using scanning electron microscopy (EDS analysis), magnetic force microscopy, and nanoindentation, a metallographic study of the magnetic structure and nanomechanical properties of sintered rare-earth magnets Nd–Dy–Fe–B of the USC-20L brand has been carried out (Ural Strip Casting Technology). The microstructure of the sintered Nd–Dy–Fe–B magnet of the USC-20L grade includes the following components: grains of the Nd2Fe14B phase are separated by lamellas of the phases enriched in neodymium. Inclusions Nd–29.1% Fe–6.2% C–2.2% O–1.4% Dy are located at the triple junctions of Nd2Fe14B grains. Inclusions Nd–4.5% Fe–9.1% O–6.7% C–4.5% Fe–2% Dy are along grain boundaries containing Nd and Dy oxides. The chemical composition of grains is Fe–25% Nd–6.9% C–1.6% Dy–1.4% B. It is found that, due to irregular grain growth, the interlayers of the enriched Nd phase are connected to each other in the region of grain junctions, causing a concentration of internal stresses and the appearance of a crack. The crack propagates along the grain boundary from one wetted joint of the grains to another, due to mechanical stresses. The phenomenon of intergranular wetting by a phase of Nd-enriched Nd2Fe14B/Nd2Fe14B grain boundaries is observed. It has been established that phases enriched with Nd can pseudo-incompletely (or pseudo-partially) wet such grain boundaries, i.e., form a nonzero contact angle along the grain boundaries and in triple joints. Based on the results of Magnetic Force Microscopy (MFM), a conclusion is made about the presence of a one-dimensional domain structure; domains cross grain boundaries. The presence of pores and inclusions of Nd and Dy oxides localized along grain boundaries is noteworthy. The average transverse domain size of the banded structure is ~1 μm, the energy of the domain wall γ ~ 14 kJ/m2, and the width of the domain wall δ ~ 0.6 × 10–9 m. The nanoindentation method is used to measure the values of nanohardness (H, GPa), elastic modulus (E, GPa), contact stiffness (S, N/m), elastic work (We, nJ) and plastic strain (Wp, nJ) in submicrovolumes of Nd2Fe14B grains. According to the measurement results, the minimum value of Nd2Fe14B grain adhesion Kint = 0.539 MPa m0.5 is estimated.

Similar content being viewed by others

REFERENCES

Aich, S., Satapathy, D.K., and Shield, J.E., Rapidly solidified rare-earth permanent magnets: Processing, properties, and applications, in Advances in Magnetic Materials: Processing, Properties, and Performance, Zhang, S. and Zhao, D., Eds., Boca Raton, FL: CRC Press, 2017, pp. 453–508.

Hattori, T., Fukamachi, N., Goto, R., Tezuka, N., and Sugimoto, S., Microstructural evaluation of Nd–Fe–B strip cast alloys, Mater. Trans., 2009, vol. 50, no. 3, pp. 479–482.

Wang Xiaoli, Zhao Lina, Ding Kaihong, Cui Shengli, Sun Yongcong, and Li Musen, Influence of dysprosium distribution on properties of sintered and aged Dy-doped NdFeB permanent magnets, Rare Met. Mater. Eng., 2016, vol. 45, no. 2, pp. 0309–0314.

Vasilenko, D.Yu., Shitov, A.V., Vlasyuga, A.V., Popov, A.G., Kudrevatykh, N.V., and Pechishcheva, N.V., Microstructure and properties of Nd–Fe–B alloys produced by strip casting and of permanent magnets fabricated from them, Met. Sci. Heat Treat., 2015, vol. 56, nos. 11–12, pp. 585–590

Bernardi, J., Filer, J., Sagawa, M., and Hirose, Y., Microstructural analysis of strip cast Nd–Fe–B alloys for high (BH)max magnets, J. Appl. Phys., 1998, vol. 83, no. 11, pp. 6396–6398.

Glebov, V.A., Glebov, A.V., Bakulina, A.S., Efremov, I.V., Ivanov, S.I., Safronov, B.V., Shingarev, E.N., Vyatkin, V.P., Vasilenko, D.Yu., Bratushev, D.Yu., Popov, A.G., Puzanova, T.Z., and Kudrevatykh, N.V., Investigation of the first domestic magnetic alloys produced by “strip casting” technology, Fiz. Khim. Obrab. Mater., 2011, no. 3, pp. 16–20.

Popov, A.G., Vasilenko, D.Y., Puzanova, T.Z., Vlasyuga, A.V., and Vyatkin, V.P., Highly coercive sintered magnets from (Nd, Dy)–Fe–B alloys fabricated by the method of strip casting, Met. Sci. Heat Treat., 2013, vol. 55, nos. 1–2, pp. 78–82.

Öztürk, S., İcin, K., Öztürk, B., Topal, U., Enstitüsü, T.U.M., and Kaftelen, H., Structural, thermal and magnetic characterization of rapidly solidified Nd–Fe–B hard magnetic alloy powder, UEMK 2016 Conference Proc.: Int. Conference on Material Science and Technology in Cappadocia (IMSTEC'16), Nevsehir, April 6–9, 2016, pp. 67–79.

Zhou, T., Xie, W., Liu, R., Rehman, S.U., Zhong, Z., Zhong, M., and Huang, R., Fracture behavior of sintered NdFeB magnets during cooling from sintering temperature, Mater. Res. Express, 2019, vol. 6, no. 12, article no. 126106.

Greer, J., Petruska, A.J., Mahoney, A.W., Nambi, M., Bamberg, E., and Abbott, J.J., Experimental investigation of wire electrical discharge machining of NdFeB permanent magnets with an RC-type machine, J. Mater. Eng. Perform., 2014, vol. 23, no. 4, pp. 1392–1401.

Li, L., Wei, X.T., Li, Z.Y., and Cheng, X., Corrosion resistance analysis of sintered NdFeB magnets using ultrasonic-aided EDM method, J. Mater. Eng. Perform., 2015, vol. 24, no. 1, pp. 536–542.

Li, L., Cheng, X., Sima, Z., and Niu, Z., Machinability of NdFeB magnet via wire and sinking EDM methods, Indian J. Eng. Mater. Sci., 2015, vol. 22, no. 4, pp. 407–413.

Kazakova, O., Puttock, R., Barton, C., Corte-León, H., Jaafar, M., Neu, V., and Asenjo, A., Frontiers of magnetic force microscopy, J. Appl. Phys., 2019, vol. 125, no. 6, article no. 060901.

Neu, V., Vock, S., Sturm, T., and Schultz, L., Epitaxial hard magnetic SmCo5 MFM tips —A new approach to advanced magnetic force microscopy imaging, Nanoscale, 2018, vol. 10, pp. 16881–16886.

GOST (State Standard) no. R 8.748–2011: State System for Ensuring the Uniformity of Measurements. Metallic Materials. Instrumented Indentation Test for Hardness and Materials Parameters. Part 1. Test Method, Moscow: Standartinform, 2013.

Nano-Hardness Testers NanoSkan-4D. Technical Conditions. TU 4271-049-48786949-2014 (NUMK.421452.002 TU).

Golovin, Yu.I., Nanoindentation and mechanical properties of solids in submicrovolumes, thin near-surface layers, and films: A review, Phys. Solid State, 2008, vol. 50, no. 12, pp. 2205–2236.

Oliver, W.C. and Pharr, G.M., An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments, J. Mater. Res., 1992, vol. 7, no. 6, pp. 1564–1583.

Greer, J., Petruska, A.J., Mahoney, A.W., Nambi, M., Bamberg, E., and Abbott, J.J., Experimental investigation of wire electrical discharge machining of NdFeB permanent magnets with an RC-type machine, J. Mater. Eng. Perform., 2014, vol. 23, no. 4, pp. 1392–1401.

Coey, J.M.D., Hard magnetic materials: A perspective, IEEE Trans. Magn., 2011, vol. 47, no. 12, pp. 4671–4681.

Kucheryaev, V.V., Valeev, R.A., Korolev, D.V., Piskorskiy, V.P., Koplak, O.V., and Morgunov, R.B., Analysis of distribution of the surface magnetic-field gradient in (PrDy)(FeCo)B rare-earth magnets, J. Surf. Invest.: X‑Ray, Synchrotron Neutron Tech., 2018, vol. 12, no. 5, pp. 939–943.

De Campos, M.F., Effect of grain size on the coercivity of sintered NdFeB magnets, Mater. Sci. Forum, 2010, vols. 660–661, pp. 284–289.

Collocott, S.J. and Dunlop, J.B., The fluctuation field and anomalous magnetic viscosity in commercial NdFeB alloys, AlNiCo and the bulk amorphous ferromagnets Nd60Fe30Al10 and Nd60Fe20Co10Al10, J. Magn. Magn. Mater., 2008, vol. 320, no. 16, pp. 2089–2093.

Szmaja, W., Investigations of the domain structure of anisotropic sintered Nd–Fe–B-based permanent magnets, J. Magn. Magn. Mater., 2006, vol. 301, pp. 546–561.

Chikova, O., Sinitsin, N., Vyukhin, V., and Chezganov, D., Microheterogeneity and crystallization conditions of Fe–Mn melts, J. Cryst. Growth, 2019, vol. 527, article no. 125239.

Zhang, C., Zhou, H., and Liu, L., Laminar Fe-based amorphous composite coatings with enhanced bonding strength and impact resistance, Acta Mater., 2014, vol. 72, pp. 239–251.

Chia, F., Wießnera, L., Gröbb, T., Bruderb, E., Sawatzkic, S., Löwec, K., Gassmannd, J., Müllerb, C., Durstb, K., Gutfleischc, O., and Grochea, P., Towards manufacturing of Nd-Fe-B magnets by continuous rotary swaging of cast alloy, J. Magn. Magn. Mater., 2019, vol. 490, article no. 165405.

Li, W.F., Sepehri-Amin, H., Ohkubo, T., Hase, N., and Hono, K., Distribution of Dy in high-coercivity (Nd,Dy)–Fe–B sintered magnet, Acta Mater., 2011, vol. 59, no. 8, pp. 3061–3069.

Mazilkin, A., Straumal, B., Protasova, S., and Baretzky, B., Grain boundary wetting in the Nd–Fe–B-based alloy, Defect Diffus. Forum, 2017, vol. 380, pp. 173–180.

Straumal, B.B., Mazilkin, A.A., Protasova, S.G., Gusak, A.M., Bulatov, M.F., Straumal, A.B., and Baretzky, B., Grain boundary phenomena in NdFeB-based hard magnetic alloys, Rev. Adv. Mater. Sci., 2014, vol. 38, no. 1, pp. 17–28.

ACKNOWLEDGMENTS

This work was carried out using equipment of the Modern Nanotechnologies Ural Center of Collective Use at the Institute of Natural Sciences and Mathematics, Ural Federal University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by A. Muravev

About this article

Cite this article

Slinkin, I.V., Chikova, O.A. Magnetic Structure and Nanomechanical Properties of Sintered Permanent Magnets Nd–Dy–Fe–B USC-20L. Russ. J. Non-ferrous Metals 61, 623–631 (2020). https://doi.org/10.3103/S1067821220060218

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220060218