Abstract

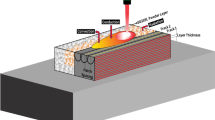

In this paper, the mathematical simulation of laser melting of wear-resistant plasma coatings is considered. The results of numerical study of the influence of the heat flow and thermophysical properties of the materials on the heating and melting processes are presented. Application programs are developed to optimize the process of laser melting of the surface layer for surfacing the wear-resistant coatings and surface melting using the additive laser technology.

Similar content being viewed by others

REFERENCES

Grigor’yants, A.G., Misyurov, A.I., Shiganov, I.N., et al., Porosity investigation of the cobalt- and nickel-based laser coatings, Vestn. MGTU N.E. Baumana, Ser. Mashinostr., 2012, no. 6, p. 165.

Ivensen, B.A., Kinetika uplotneniya metallicheskikh poroshkov pri spekanii (Kinetics of Compaction of Metal Powders during Sintering), Moscow: Metallurgiya, 1971, p. 256.

Alisin, V.V., Vladislavlev, A.A., and Roshchin, M.N., Physical simulation of the fusion process for wear resistant plasma coatings production by laser treatment, Trenie Smazka Mash. Mekh., 2008, no. 11, p. 17.

Alisin, V.V., Vladislavlev, A.A., and Roshchin, M.N., Technology for producing wear-resistant cermet coatings with ultrafine hardening phase, in Perspektivnye materialy i tekhnologii. NANOKOMPOZITY, Kosmicheskii vyzov 21 vek (Perspective Materials and Technologies, Nanocomposites, Vol. 2 of 21st Century Space Call), Berlin, A.A. and Assovskii, I.G., Eds., Moscow: Torus Press, 2006, p. 59.

Raikis, O. and Shopkhoven, T., Alternative of future: high-speed laser cladding is coming to replace hard chromium plating, Fotonika, 2016, no. 3/57, p. 28.

Kablov, E.N., Additive technology are the dominant of the national technology initiative, Intell. Tekhnol., 2015, no. 2 (11), p. 52.

Anan’ev, A.I., Shibalov, M.V., Kurkov, A.A., et al., Studies of microstructure and properties of the 316L chrome-nichel steel, obtained by selective laser melting method, Vestn. NPO im. S.A. Lavochkina, 2017, no. 3, p. 54.

Morgan, K., Sutcliffe, C.J., and Oneil, W., Density analysis of direct laser re-melted 316 stainless steel cubic primitives, J. Mater. Sci., 2004, no. 39, p. 1195.

Gordeev, G.A., Krivlev, M.D., and Ankudinov, V.E., Computer simulation of selective laser melting of fine-grained metallic powders, Vychisl. Mekh. Splosh. Sred, 2017, vol. 10, no. 3, p. 293.

Dubourg, L. and St-Georges, L., Optimization of laser cladding process using taguchi and em methods for mmc coating production, J. Therm. Spray Technol., 2006, vol. 15, p. 790.

Hodge, N.E., Ferencz, R.M., and Solberg, J.M., Implementation of a thermomechanical model for t simulation of selective laser melting, Comput. Mech., 2014, vol. 54, no. 1, p. 33.

Volkov, E.A., Chislennye metody (Numerical Methods), Moscow: Nauka, 1982, p. 256.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by N. Semenova

About this article

Cite this article

Alisin, V.V., Roshchin, M.N. Numerical Analysis of Heat Flows in the Process of Laser Melting of Coatings. J. Mach. Manuf. Reliab. 48, 361–367 (2019). https://doi.org/10.3103/S1052618819040046

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618819040046