Abstract

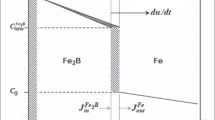

The purpose of the study is to identify transitional diffusion layers in the steel wire-brass coating system. Brass-plated wire is used in the production of steel cord. The authors use brass-plated wire made of steel 80 by dry drawing, two-stage deposition of a brass coating (copper + zinc), and subsequent diffusion annealing. The chemical composition is determined with a scanning electron microscope TESCAN Vega3 SBH equipped with a device for X-ray microanalysis (MRSA) by Oxford Instruments using framing to obtain elements distribution maps. In the study of the chemical composition of the steel wire brass coating under the metal cord, the copper concentration gradient is determined from the spectra, the iron content in the coating and the copper content in the steel core are established. The authors determine the presence of a transitional diffusion layer from a brass coating to a steel core of a wet-drawn wire with a diameter of 1.67 and 1.85 mm in two sections with different thicknesses of a brass coating in opposite sections (maximum and minimum). The article contains an elemental distribution map of Fe, Cu and Zn, as well as a general superposition map of Fe, Cu and Zn. Graphs of the content for two studied cross sections are presented. The transition diffusion layer has a gradient transition in the concentrations of Fe, Cu and Zn, which characterizes a good connection of the brass coating with steel. The diffusion layer of the brass coating of a steel wire with a diameter of 0.30 mm, produced by wet drawing of a steel wire with a diameter of 1.67 mm, is studied. A coating image is obtained by framing. The coating thickness along with the diffusion layer has an average value of 1.4 μm with an apparent coating thickness of 0.5 μm.

Similar content being viewed by others

REFERENCES

Alekseev, Yu.G. and Kuvaldin, N.A., Metallokord dlya avtomobil’nykh shin (Steel Cord for Car Tires), Moscow: Metallurgiya, 1992.

Ugaste, Yu.E., Kodentsov, A.A., and van Loo, F., Redistribution of concentration of components during interdiffusion in Cu–Fe–Ni system, Phys. Met. Metallogr., 2012, vol. 113, no. 12, pp. 1182–1192. https://doi.org/10.1134/S0031918X12120125

Nechaykina, T., Molotnikov, A., Estrin, Y., Nikulin, S., Rozhnov, A., Zavodchikov, S., and Estrin, Y., Proving the viability of manufacturing of multi-layer steel/vanadium alloy/steel composite tubes by numerical simulations and experiment, J. Nucl. Mater., 2018, vol. 503, pp. 178–190. https://doi.org/10.1016/j.jnucmat.2018.02.043

Nechaikina, T.A., Nikulin, S.A., Rogachev, S.O., Turilina, V.Yu., and Baranova, A.P., Stability of the transition zones in a steel–vanadium alloy–steel sandwich after thermomechanical treatment, Steel Transl., 2018, vol. 48, no. 6, pp. 346–351. https://doi.org/10.3103/S0967091218060062

Andrianov, N.V., Savenok, A.N., Kravtsov, A.A., and Ledneva, A.A., Adhesion of rubber to steel cord and its preservation, Lit’e Metall., 2005, no. 2, pp. 36–44.

Shmurak, I.L., Matyukhin, S.A., and Dashevskii, L.I., Tekhnologiya krepleniya shinnogo korda k rezine (Technology for Attaching a Tire Cord to Rubber), Moscow: Khimiya, 1993.

Kuvaldin, N.A., Electroplated brass plating of wire for steel cord, Extended Abstract of Cand. Sci. (Eng.) Dissertation, Dnepropetrovsk, 1992, p. 25.

Moskalev, D.N., Tsyganov, I.A., and Mochalin, I.M., The research of the brass coating thickness for steel cord, Gal’vanotekh. Obrab. Poverkhn., 2020, vol. 28, no. 1, pp. 346–351. https://doi.org/10.47188/0869-5326_2020_28_1_11

Lobanov, M.L., Kardonina, N.I., Rossina, N.G., and Yurovskikh, A.S., Zashchitnye pokrytiya. Uchebnoe posobie (Protective Coatings: Textbook), Yekaterinburg: Izd-vo Ural’skogo Univ., 2014.

Geguzin, Ya.E., Ocherki o diffuzii v kristallakh (Essays on Diffusion in Crystals), Moscow: Nauka, 1974, 2nd ed.

Girin, O.B. and Kovenskii, I.M., Features of formation of crystal structure defects in electrodeposited metals, Vost.-Evr. Zh. Peredovykh Tekhnol., 2012, vol. 2, no. 5 (56), pp. 44–47.

Povetkin, V.V. and Kovenskii, I.M., Struktura elektroliticheskikh pokrytii (Structure of Electrolytic Coatings), Moscow: Metallurgiya, 1989.

Tashiro, H. and Tarui, T., State of the art for high tensile strength steel cord, Nippon Steel Tech. Rep., 2003, no. 88, pp. 87–91.

Vinokurov, E.G., Kandyrin, K.L., and Bondar’, V.V., Modeling of the solution composition and a study of the electrodeposition of the Cu–Zn alloy, Russ. J. Appl. Chem., 2010, vol. 83, no. 4, pp. 659–663. https://doi.org/10.1134/S1070427210040166

Mikhedova, E.V., Yaskel’chik, V.V., Chernik, A.A., and Zharskii, I.M., Electrochemical deposition of yellow brass under pulse electrolysis conditions, Izv. Nats. Akad. Nauk Belarusi: Ser. Khim. Nauk, 2014, no. 3, pp. 48–52.

Denisova, A.G., Gryzunova, N.N., Vikarchuk, A.A., Shafeev, M.R., Bekin, V.V., and Gryzunov, A.M., Morphologies and phase compositions of copper–zinc coatings obtained by electrolysis, Bull. Russ. Acad. Sci.: Phys., 2017, vol. 81, no. 11, pp. 1348–1352. https://doi.org/10.3103/S1062873817110065

Saadatmand, M. and Sadeghpour, S., and Aghazadeh Mohandesi, J., Optimisation of brass plating condition in plating of patented steel wire, Surf. Eng., 2011, vol. 27, no. 1, pp. 19–25. https://doi.org/10.1179/026708410X12459349719972

Moskalev, D.N. and Tsyganov, I.A. Nonuniform thickness of brass coating on fine wire with diameter of 0.30 mm, Materialy oblastnogo profil’nogo seminara Shkola molodykh uchenykh po problemam tekhnicheskikh nauk (Materials of the Regional Special Seminar School of Young Scientists on the Problems of Technical Sciences), Lipetsk: Izdatel’stvo Lipetskogo Gos. Tekh. Univ., 2021. pp. 20–22.

CONFLICT OF INTEREST

The authors declare that they have no conflicts of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Kolemesin

About this article

Cite this article

Moskalev, D.N., Tsyganov, I.A. Study of the Chemical Composition of a Steel Wire Brass Coating for Steel Cord Production. Steel Transl. 52, 852–858 (2022). https://doi.org/10.3103/S096709122209008X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709122209008X