Abstract

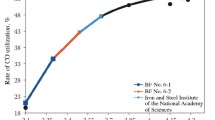

The sintering intensity is one of the important factors determining the technical and economic efficiency of sinter production which provides the blast-furnace process with the main kind of agglomerated raw iron ore. The process parameters of sintering critically influence the sinter burden caking rate. Therefore, the system study of the process parameters of sintering, which determine its intensity, is a matter of practical and scientific interest. In its purest form, it is shown that the sintering intensity is characterized by the vertical caking rate and the sinter burden carbon combustion intensity. The other two indices, including the specific performance for suitable sinter cake and the heat output intensity in the combustion zone, are less representative for the comparative estimation of the caking intensity, since their values depend on the sintered mass strength and the thermal effect of carbon combustion, respectively. These factors go beyond the essence of the sintering intensity concept. Since the content of 5 to 0 mm fines is different at different sinter plants, the representative comparison by sintering performance is possible only considering the total amount of returns at the sinter plant and the 5 to 0 mm fines generated along the whole sinter cake transport path to the blast furnace or the results of the sinter cake strength test in a drum. An integrated system classification of sintering intensification techniques is developed on the basis of the material-component principle using the separation into four levels which are objects, directions, paths, and methods. According to this principle, each subsequent level becomes more specific and develops the preceding one. The merit of this classification is its generality, which makes it possible to apply this system for classifying and separating almost all the already known and future methods of sintering intensification.

Similar content being viewed by others

REFERENCES

Vegman, E.F., Pyrikov, A.N., and Zhak, A.R., Intensifikatsiya aglomeratsionnogo protsessa (Intensification of Sintering Process), Moscow: Mashinostroenie, 1995.

Shurkhal, B.A., Intensification of iron ore materials agglomeration, Chern. Metall., Byull. Nauchno-Tekh. Ekon. Inf., 1985, no. 13, pp. 7–27.

Intensifikatsiya protsessov okuskovaniya rudnykh materialov (Intensification of Ore Materials Agglomeration: Proceedings), Shurkhal, B.A., Ed., Kiev: Naukova Dumka, 1987.

Krivenko, S.V., Tomash, A.A., and Russkikh, V.P., Sintering process intensification by increasing the fuel burning rate in a layer, Met. Lit’e Ukr., 2009, nos. 7–8, pp. 63–68.

Plotnikov, V.V. and Saitgareev, L.N., Sintering process intensification by improving the technology of combined pelletizing and charge loading, Visn. Priazov. Derzh. Tekh. Univ., Tekh. Nauki, 2012, no. 25, pp. 41–46.

Besta, P. and Wicher, P., The optimization of the production of sinter as the feedstock of the blast furnace process, Metalurgija, 2017, vol. 56, nos. 1–2, pp. 131–134.

Sintering plant at a glance. https://vdocuments.mx/ sintering-plant-at-a-glance.html.

Korotich, V.I., Frolov, Yu.A., and Bezdezhskii, G.N., Aglomeratsiya rudnykh materialov (Sintering of Ore Materials), Yekaterinburg: Ural. Gos. Tekh. Univ.-Ural. Politekh. Inst., 2003.

Savel’ev, S.G. and Shapovalov, V.A., Intensity parameters of sintering process, Visn. Krivoriz. Tekh. Univ., 2008, no. 21, pp. 78–82.

Syr’e dlya chernoi metallurgii: Spravochnoe izdanie. Tom 1. Syr’evaya baza i proizvodstvo okuskovannogo syr’ya (syr’e, tekhnologii, oborudovanie) (Raw Materials for Ferrous Metallurgy: Handbook, Vol. 1: Raw Material Resources and Production of Agglomerated Raw Materials (Raw Materials, Technologies, and Equipment)), Chizhikova, V.M., Ed., Moscow: Mashinostroenie, 2001.

Savel’ev, S.G. and Velikokhat’ko, Ya.A., Mathematical modeling of combustion zone movement during sintering charge agglomeration, Visn. Krivoriz. Tekh. Univ., 2014, no. 37, pp. 108–113.

Savel’ev, S.G., Development of representations on thermal indicators of the agglomeration process, Metalurgiya, 2017, no. 2 (38), pp. 81–84.

Zhuravlev, F.M., Lyalyuk, V.P., Kassim, D.A., et al., Agglomerated, fully ofluõed iron ore material for blast furnace smelting with the best characteristics of sinter and pellets, Chern. Metall., Byull. Nauchno-Tekh. Ekon. Inf., 2015, no. 1, pp. 31–38.

Semakova, V.B. and Pilyugin, E.I., Research of sintering process produc tivity indicators, Visn. Priazov. Derzh. Tekh. Univ., Tekh. Nauki, 2015, no. 1 (30), pp. 41–50.

Lotosh, V.E., Fundamental’nye osnovy prirodopol’zovaniya. Kniga 1. Tekhnologii osnovnykh proizvodstv v prirodopol’zovanii (Fundamental Principles of Nature Management, Book 1: General Production Technologies in Nature Management), 4th ed., Yekaterinburg: Ural. Univ. Putei Soobshch., 2007.

Boranbaev, B.M., Minakov, N.S., Yusfin, Yu.S., et al., USSR Inventor’s Certificate no. 1790616, Byull. Izobret., 1993, no. 3.

Bezverkhii, I.V. and Tomash, A.A., Influence of intensifying factors on sintering process indicators, Nauk. Pr. Donsk. Nats. Tekh. Univ., Metall., 2009, no. 11 (159), pp. 3–12.

Tovarovskii, I.G., Normative assessment of impact of blast furnace smelting parameters on coke consumption and productivity, in Fundamental’nye i Prikladnye Problemy Chernoi Metallurgii (Fundamental and Applied Problems of Ferrous Metallurgy), Dnepropetrovsk: Inst. Chern. Metall., Nats. Akad. Nauk Ukr., 2014, no. 28, pp. 117–131.

Korotich, V.I., Osnovy teorii i tekhnologii podgotovki syr’ya k domennoi plavke (Fundamental Theory and Technology of Raw Materials Preparation for Blast Furnace Melting), Moscow: Metallurgiya, 1978.

Lyalyuk, V.P., Stupnik, N.I., Zhuravlev, F.M., et al., Sovershenstvovanie tekhnologii i oborudovaniya proizvodstva zheleznorudnogo syr’ya dlya sovremennoi domennoi plavki (Improving the Technology and Equipment for Iron Ore Raw Materials Production for Modern Blast Furnace Smelting), Krivoi Rog: Dionat, 2017.

Zasel’skii, V.I. and Popolov, D.V., Improving the quality of sinter and productivity of the sintering machine by charge pressing, Chern. Metall., Byull. Nauchno-Tekh. Ekon. Inf., 2010, no. 5, pp. 34–36.

Datta, S.S., Das, B.K., Balaji, S.A., and Das, A., Process improvement in sintering by bed humidification, Proc. AISTech 2006 the Iron & Steel Technology Confe. and Exposition, Cleveland, OH, 2006, vol. 1, pp. 207–213.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by S. Kuznetsov

About this article

Cite this article

Savel’ev, S.G., Kondratenko, M.N. System Study of Process Parameters Determining the Sintering Intensity. Steel Transl. 51, 149–155 (2021). https://doi.org/10.3103/S0967091221030104

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091221030104