Abstract

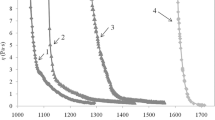

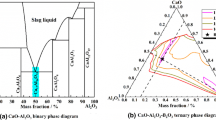

The simplex lattice method has been applied to studying the chemical composition influence of CaO–SiO2–B2O3 oxide system containing 15% Al2O3 and 8% MgO on viscosity and solidification point (hereinafter wt % are used). The addition of boron oxide to slags of the considered oxide system expands the range of slag composition with low solidification point and viscosity. The slags with basicity of 2.0–3.0 containing 1– 3% B2O3 are characterized by low (1400–1450°C) solidification point and high viscosity. Viscosity of such slags upon their heating to 1550 and 1600°C does not exceed 0.20 and 0.15 Pa s, respectively. An increase in B2O3 content to 4–6% in slags with basicity of 2.0–3.0 is accompanied by a decrease in solidification point to 1350–1425°C with retention of low (not higher than 0.15 Pa s) viscosity at heating temperature of 1550 and 1600°C. Generated slag displacement containing 1–6% B2O3 to the basicity regions increasing to 3.0–5.0 retains a sufficiently high fluidity. Herewith, it can be observed that the considered oxide system is displaced to a low solidification point region with an increase in boron oxide concentration. A slag solidification point with basicity of 3.0–4.0 containing 6% B2O3 reaches 1400°C and actually does not exceed 1475°C for the slags with basicity of 4.0–5.0 containing 1–2% B2O3. At 1600°C, the slag viscosity varies from 0.15 Pa s at basicity of 3.0 and B2O3 content of 5– 6% to 0.25 Pa s at basicity of 4.0–5.0 and B2O3 content of 1–3%. A temperature decrease of the considered oxide system by 50°C is accompanied by an insignificant (not more than 0.05 Pa s) increase in viscosity.

Similar content being viewed by others

REFERENCES

Dyudkin, D.A. and Kisilenko, V.V., Proizvodstvo stali. Tom 3. Vnepechnaya metallurgiya stali (Steel Production, Vol. 3: Out-of Ladle Metallurgy of Steel), Moscow: Teplotekhnik, 2010.

Popel’, S.I., Sotnikov, A.I., and Boronenkov, V.N., Teoriya metallurgicheskikh protsessov (Theory of Metallurgical Processes), Moscow: Metallurgiya, 1986.

Sokolov, G.A., Vnepechnoe rafinirovanie stali (Ladle Refining of Steel), Moscow: Metallurgiya, 1977.

Arsent’ev, P.P., Yakovlev, V.V., Krasheninnikov, M.G., Pronin, L.A., and Filippov, E.S., Fiziko-khimicheskie metody issledovaniya metallurgicheskikh protsessov (Physico-Chemical Methods in Study of Metallurgical Processes), Moscow: Metallurgiya, 1988.

Yavoiskii, V.I. and Yavoiskii, A.V., Nauchnye osnovy sovremennykh protsessov proizvodstva stali (Scientific Basis of Modern Steel Production Processes), Moscow: Metallurgiya, 1987.

Wang, H.M., Zhang, T.W., Zhu, H., Yan, Y.Q., and Zhao, Y.N., Effect of B2O3 and CaF2 on viscosity of ladle refining slag, Adv. Mater. Res., 2011, vols. 295–297, pp. 2647–2650.

Ko, K.Y. and Park, J.H., Effect of CaF2 addition on the viscosity and structure of CaO–SiO2–MnO slags, ISIJ Int., 2013, vol. 53, no. 6, pp. 958–965.

Choi, S.Y., Lee, D.H., Shin, D.W., Choi, S.Y., Cho, J.W., and Park, J.M., Properties of F-free glass system as a mold flux: viscosity, thermal conductivity and crystallization behavior, J. Non-Cryst. Solids, 2004, vols. 345–346, pp. 157–160.

Nakada, H. and Nagata, K., Crystallization of CaO–SiO2–TiO2 slag as a candidate for fluorine free mold flux, ISIJ Int., 2006, vol. 46, no. 3, pp. 441–449.

Persson, M., Seetharaman, S., and Seetharaman, S., Kinetic studies of fluoride evaporation from slags, ISIJ Int., 2007, vol. 47, no. 12, pp. 1711–1717.

Akberdin, A.A., Kulikov, I.S., Kim, V.A., et al., Fizicheskie svoistva rasplavov sistemy CaO–Al2O3–SiO2–MgO–CaF2 (Physical Properties of the Melts of CaO–Al2O3–SiO2–MgO–CaF2 System), Moscow: Metallurgiya, 1987.

Hongming, W., Tingwang, Z., and Hua, Z., Effect of B2O3 on melting temperature, viscosity and desulfurization capacity of CaO-based refining flux, ISIJ Int., 2011, vol. 51, no. 5, pp. 702–708.

Akberdin, A.A., Kireeva, G.M., and Medvedovskaya I.A., Effect of B2O3 on viscosity of the slags of CaO–Al2O3–SiO2 system, Izv. Akad. Nauk SSSR, Met., 1986, no. 3, pp. 55–56.

Babenko, A.A., Istomin, S.A., Protopopov, E.V., Sychev, A.V., and Ryabov, V.V., Viscosity of CaO–SiO2–Al2O3–MgO–B2O3 slags, Steel Transl., 2014, vol. 44, no. 2, pp. 110–112.

Wang, H.-M., Li, G.-R., Li, B., Zhang, X.-J., and Yan, Y.-Q., Effect of B2O3 on melting temperature of CaO-based ladle refining slag, ISIJ Int., 2010, vol. 17, no. 10, pp. 18–22.

Wamg, H., Li, G., and Dai, R., CAS-OB: refining slag modification with B2O3–CaO and CaF2–CaO, Ironmaking Steelmaking, 2007, vol. 34, no. 4, pp. 350–353.

Zhang, L., Wang, W., Xie, S., Zhang, K., and Sohn, I., Effect of basicity and B2O3 on the viscosity and structure of fluorine-free mold flux, J. Non-Cryst. Solids, 2017, vol. 460, no. 4, pp. 113–118.

Sun, Y.Q., Liao, J.L., Zheng, K., Wang, X.D., and Zhang, Z.T., Effect of B2O3 on the structure and viscous behavior of Ti-bearing blast furnace slags, JOM, 2014, vol. 66, no. 10, pp. 2168–2175.

Kim, V.A., Nikolai, E.N., Akberdin, A.A., et al., Planirovanie eksperimenta pri issledovanii fiziko-khimicheskikh svoistv metallurgicheskikh shlakov. Metodicheskoe posobie (Experiment Planning in Study of Physicochemical Properties of Metallurgical Slag: Practical Manual), Alma-Ata: Nauka, 1989.

Kim, V.A., Akberdin, A.A., Kulikov, I.S., et al., Application of simplex lattice method for constructing composition-viscosity diagrams, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1980, no. 9, pp. 167–168.

Funding

This work was supported by the Government contract of Institute of Metallurgy, Ural Branch, Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by I. Moshkin

About this article

Cite this article

Babenko, A.A., Shartdinov, R.R., Upolovnikova, A.G. et al. Physical Properties of CaO–SiO2–B2O3 Slags Containing 15% Al2O3 and 8% MgO. Steel Transl. 49, 667–670 (2019). https://doi.org/10.3103/S0967091219100036

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091219100036