Abstract

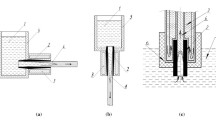

This paper presents the results of the metallographic study of the structural condition of metal in the billet after soft reduction. The billet is deformed in the withdrawal and straightening unit of the continuous casting production line when there is an uncrystallized core area in the bullet. The reduction takes place due to the movement of the top driven roll. The metallographic studies reveal the crack initiation characteristics when an external deformative action is applied in the course of incomplete crystallization of continuously cast billet. They provide a well-reasoned approach to selection of techniques minimizing the number of initiation centers.

Similar content being viewed by others

REFERENCES

Smirnov, A.N., Smirnov, E.N., Sklyar, V.A., et al., Producing structural-steel bar from continuous-cast billet, Steel Transl., 2018, vol. 48, no. 4, pp. 233–239.

Smirnov, A.N., Kuberskii, S.V., Smirnov, E.N., et al., Influence of meniscus fluctuation in the mold on crust formation in slab casting, Steel Transl., 2017, vol. 47, no. 7, pp. 476–482.

Thome, R., Ostheimer, V., Ney, G., et al., Soft reduction in the continuous casting of billets, MPT,Metall. Plant Technol. Int., 2007, vol. 30, no. 1, pp. 36–42.

Smyrnov, Y.N., Belevitin, V.A., Skliar, V.A., and Orlov, G.A., Physical and computer modeling of a new soft reduction process of continuously cast blooms, J. Chem. Technol. Metall., 2015, vol. 50, no. 6, pp. 589–594.

Masini, R. and Lainati, A., Latest bar mill technology, Millennium Steel, 2005, no. 7, pp. 216–227.

Minaev, A.A., Nosanev, A.G., Smirnov, E.N., et al., Unit for accelerated cooling of reinforcement bars in the line of a 330 mill after deformation, Metallurgist, 1990, vol. 34, no. 1, p. 32.

Chen, J., Jiang, G., and Pang, Y., Application of mold electromagnetic stirring in continuous casting of middle billet, J. Univ. Sci. Technol. Beijing, 2007, suppl. 1. http://en.cnki.com.cn/Journal_en/C-C000-BJKD-2007-S1.htm/. Accessed February 12, 2018.

Weyer, A., Letzel, D., Gärtner, H., et al., US Patent 7 121 323, 2006.

Smyrnov, Y.N., Skliar, V.A., Belevitin, V.A., et al., Defect healing in the axial zone of continuous-cast billet, Steel Transl., 2016, vol. 46, no. 5, pp. 325–328.

Kukhar, V., Prysiazhnyi, A., Balalayeva, E., and Anishchenko, O., Designing of induction heaters for the edges of pre-rolled wide ultrafine sheets and strips correlated with the chilling end effect, Proc. 2017 Int. Conf. on Modern Electrical and Energy Systems (MEES), Kremenchuk Mykhailo Ostrohradskyi National University, November 15–17,2017, Piscataway, NJ: Inst. Electr. Electron. Eng., 2017, pp. 404–407. https://doi.org/10.1109/MEES.2017.8248945.

Kukhar, V., Artiukh, V., Prysiazhnyi, A., and Pustovgar, A., Experimental research and method for calculation of ‘upsetting-with-buckling’ load at the impression-free (dieless) preforming of workpiece, E3S Web Conf., 2018, vol. 33, no. 02031. https://doi.org/10.1051/e3sconf/20183302031

Suzuki, M., Kimura, K., Kawami, A., and Mizutani, M., Rev. Met. (Paris), 1992, vol. 89, no. 1, pp. 83–92.

Isobe, K., Kusano, Y., Nogushi, S., et al., Improvement of segregation of continuously cast billets by soft reduction, Proc. Int. Symp. on Near-Net-Shape Casting in the Minimills, Vancouver, Canada, August 19–23,1995, Montreal: Can. Inst. Min., Metall., Petrol., 1995, pp. 179–192.

Ito, Y., Yamanaka, A., and Wanatabe, T., Rev. Met. (Paris), 2000, vol. 10, pp. 1171–1176.

Thome, R. and Harste, K., Principles of billet soft-reduction and consequences for continuous casting, ISIJ Int., 2006, vol. 46, no. 12, pp. 1839–1844.

Serov, A.I., Creation and development of electrometallurgical complex JSC Elektrostal (Kurakhovo, Ukraine), Met. Li’te Ukr., 2010, nos. 9–10, pp. 10–14.

Smirnov, E.N., Sklyar, V.A., Smirnov, O.E., et al., Behavior of structural defects of already-deformed continuous-cast bar on rolling, Steel Transl., 2018, vol. 48, no. 5, pp. 289–295.

Ogurtsov, A.P., Gress, A.V., and Nesvet, V.V., Structure and chemical heterogeneity of bloom blanks casted at the continuous casting machine of Dnepropetrovsk Metallurgical Plant, Protsessy Lit’ya, 2001, no. 2, pp. 18–28.

Kovalenko, V.S., Metallograficheskie reaktivy: spravochnik (Metallographic Reactives: Handbook), Moscow: Metallurgiya, 1981, 3rd ed.

Fridman, Ya.B. and Gordeeva, T.A., Stroenie i analiz izlomov metallov (The Structure and Analysis of Metal Fracture), Moscow: Kniga po Trebovaniyu, 2012.

Agamirov, L.V., Alimov, M.A., Babichev, L.P., et al., Physical and mechanical properties. Testing of metallic materials, in Mashinostroenie: Entsiklopediya (Machine Engineering: Encyclopedia), Mamaeva, E.I., Ed., Moscow: Mashinostroenie, 2010, vol. 2-1.

Solntsev, Yu.P. and Vologzhanina, S.A., Materialovedenie (Material Science), Moscow: Akademiya, 2011.

Botnikov, S.A., Sovremennyi atlas defektov nepreryvnolitoi zagotovki i prichiny vozniknoveniya proryvov kristallizuyushcheisya korochki metalla (A Modern Atlas of Defects of a Continuously Casted Billet and The Cases of Breakthroughs in a Crystallized Metal Crust), Volgograd, 2011, p. 97.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Bogacheva

About this article

Cite this article

Smirnov, E.N., Smirnov, A.N., Sklyar, V.A. et al. Study of the Structural Condition of Metal in Billet after Deformation in the Continuous-Casting Line. Steel Transl. 49, 631–637 (2019). https://doi.org/10.3103/S0967091219090122

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091219090122