Abstract

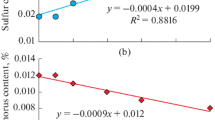

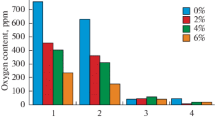

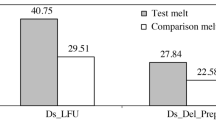

Studies of welding and surfacing fluxes containing ladle slag of electric steel production of rail steel of EVRAZ ZSMK JSC were carried out. Welding under the flux was performed on the samples of sheet steel 09G2S by Sv-08GA wire using the welding tractor ASAW1250 at exhaust modes. Chemical compositions of welding fluxes and slag crusts were determined. Also, chemical composition of the studied welded samples was determined according to GOST 10543–98 by X-ray fluorescence method on XRF-1800 spectrometer and by atomic emission method on DFS-71 spectrometer. Metallographic studies were carried out with the use of an OLYMPUS GX-51 optical microscope. The content of total oxygen and surface oxygen was studied using the LECO TC–600 analyzer. The possibility of using technogenic waste products of metallurgical production is shown for the production of welding fluxes. The following components were used for production of welding flux: ladle slag of electric steelmaking of rail steel from EVRAZ ZSMK JSC; BSK barium-strontium modifier produced under the terms of 1717-001-75073896–2005 by NPK Metallotekhnoprom; slag of silicomanganese production from West Siberian steel plant; electro static dust of aluminum production from RUSAL (carbonfluor-containing supplement). The studies have shown the suitability of the use of ladle electric steel slag for welding and surfacing of alloyed metal. The introduction of various flux additives reduces the concentration of total oxygen in the weld metal, which in turn increases the toughness. From the point of oxygen concentration in weld metal and impact toughness, it is better to use silica-manganese slag and carbon-fluoride additive as flux additives.

Similar content being viewed by others

REFERENCES

Gulyaev, A.P., Metallovedenie. Uchebnik dlya vuzov (Metal Science: Manual for Higher Education Institutions), Moscow: Metallurgiya, 1986.

Povolotskii, D.Ya., Roshchin, V.E., and Mal’kov, N.V., Elektrometallurgiya stali i ferrosplavov: uchebnik dlya vuzov (Electrometallurgy of Steel and Ferroalloys: Manual for Higher Education Institutions), Moscow: Metallurgiya, 1995.

Titarenko, V.I., Golyakevich, A.A., Orlov, L.N., Mosypan, V.V., Babenko, M.A., Telyuk, D.V., and Tarasenko, V.V., Restoration surfacing of rolling mills rolls with flux-cored wire, Svar. Proizvod., 2013, no. 7, pp. 29–32.

Kondratiev, I.A. and Ryabtsev, I.A., Flux-cored wires for surfacing of steel rollers for hot rolling, Paton Weld. J., 2014, no. 6, pp. 95–96.

Crespo, A.C., Puchol, R.Q., Goncalez, L.P., et al., Obtaining a submerged arc welding flux of the MnO–SiO2–CaO–Al2O3–CaF2 system by fusion, Weld. Int., 2007, vol. 21, no. 7, pp. 502–511.

Naumov, S.V., Kanina, A.E., Ignatova, A.M., and Ignatov, M.N., Fractional composition of welding fluxes, Nauchno-Tekh. Vestn. Povolzh., 2012, no. 2, pp. 126–169.

Golovko, V.V. and Potapov, N.N., Special features of agglomerated (ceramic) fluxes in welding, Weld. Int., 2011, vol. 25, no. 11, pp. 889–893.

Ogarkov, N.N. and Belyaev, A.I., Stoikost’ i kachestvo prokatnykh valkov (Durability and Quality of Mill Rolls), Magnitogorsk: Magnitogorsk. Gos. Tekh. Univ., 2008.

Volobuev, Yu.S., Surkov, A.V., Volobuev, O.S., et al., The development and properties of a new ceramic flux used for reconditioning rolling stock components, Weld. Int., 2010, vol. 24, no. 4, pp. 298–300.

Rybin, V.V., Kalinnikov, V.T., Brusnitsyn, Yu.D., et al., High-quality components of welding materials from minerals of the Kola Peninsula and mining wastes, Materialy nauchno-tekhnicheskoi konferentsii “Nauchnye osnovy khimii i tekhnologii pererabotki kompleksnogo syr’ya i sinteza na ego osnove funktsional’nykh materialov” (Proc. Sci.-Tech. Conf. “Scientific Basis of Chemistry and Recycling Technology of Complex Raw Materials and Synthesis of Functional Materials Based on These”), Apatity: Kol’sk. Nauchn. Tsentr, Ross. Akad. Nauk, 2008, vol. 1, pp. 22–23.

Bublik, O.V. and Chamov, S.V., Advantages and shortcomings of ceramic (agglomerated) fluxes in comparison with fused fluxes used for the same applications, Weld. Int., 2010, vol. 24, no. 9, pp. 730–733.

Parshin, S.G., Using ultrafine particles of activating fluxes for increasing the productivity of MIG/MAG welding of steels, Weld. Int., 2012, vol. 26, no. 10, pp. 800–804.

Shebanits, E.N., Omel’yanenko, N.I., Kurakin, Yu.N., Matvienko, V.N., Leshchinskii, L.K., Dubinskii, B.E., and Stepnov, K.K., Improving the fracture toughness and wear resistance of hard-faced hot-rolling-mill rolls, Metallurgist, 2012, vol. 56, nos. 7–8, pp. 613–617.

Volobuev, Yu.S., Volobuev, O.S., Parkhomenko, A.G., Dobrozhela, E.I., and Klimenchuk, O.S., Using a new general-purpose ceramic flux SFM-101 in welding of beams, Weld. Int., 2012, vol. 26, no. 8, pp. 649–653.

Pavlov, I.V. and Oleinichenko, K.A., Regulating generation of CO by varying the composition of ceramic fluxes, Weld. Int., 1995, vol. 9, no. 4, pp. 329–332.

Kazakov, Yu.V., Koryagin, K.B., and Potekhin, V.P., Effect of activating fluxes on penetration in welding steels thicker than 8 mm, Weld. Int., 1991, vol. 5, no. 3, pp. 202–205.

Gur’ev, S.V., Pletnev, Yu.M., and Murav’ev, I.I., Investigation of the properties of welded joints produced by welding in a gas mixture and under a flux, Weld. Int., 2012, vol. 26, no. 8, pp. 646–648.

Potapov, N.N., Feklistov, S.I., Volobuev, Yu.S., and Potekhin, V.P., A method of selecting fused fluxes in welding pearlitic-ferritic steel, Weld. Int., 2009, vol. 23, no. 10, pp. 800–803.

Kozyrev, N.A., Kryukov, R.E., Umanskii, A.A., Mikhno, A.R., and Dumova, L.V., Investigation and development of welding fluxes with the use of ladle electric-furnace slag and barium-strontium modifier for rolls surfacing, Izv. Vyssh. Uchebn. Zaved., Chern.Metall., 2018, vol. 61, no. 4, pp. 274–279.

Kozyrev, N.A. and Kryukov, R.E., Effective use of silicomanganese slag in welding fluxes production, Trudy mezhdunarodnoi nauchno-prakticheskoi konferentsii “Innovatsii v toplivno-energeticheskom komplekse i mashinostroenii,” 18–21 aprelya 2017 g. (Proc. Int. Sci.-Pract. Conf. “Innovations in Fuel and Energy Complex and Engineering,” April 18–21, 2017), Kemerovo: Kuzbass. Gos. Tekh. Univ., 2017, pp. 133–139.

Kislov, A.I., Mikhno, A.R., and Kozyrev, N.A., Investigation of welding fluxes on the basis of silicomanganese slag and ladle electric steel slag, Materialy Vserossiiskoi nauchnoi konferentsii studentov, aspirantov i molodykh uchenykh “Nauka i molodezh’: problemy, poiski, resheniya,” 13–15 iyunya 2018 g. (Proc. All-Russ. Sci. Conf. of Students, Post-Graduate Students, and Young Scientists “Science and Youth: Problems and Solutions,” June 13–15, 2018), Novokuznetsk: Sib. Gos. Tekh. Ind. Univ., 2018, no. 22, part 2, pp. 208–210.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by S. Avodkova

About this article

Cite this article

Kozyrev, N.A., Mikhno, A.R., Kryukov, R.E. et al. Effect of Additives Introduction to Fluxes Manufactured from Ladle Electric Steel Slag. Steel Transl. 49, 504–509 (2019). https://doi.org/10.3103/S0967091219080072

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091219080072