Abstract

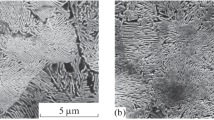

The operational wear of rails is analyzed and the actual wear is determined in measurements within the OAO RZhD network and in the laboratory. The wear resistance of rail steel is investigated as a function of the chemical composition and the microstructure (specifically, the dispersity). The microstructure of rail steel with different wear resistance is investigated by means of an electron microscope. Metallurgical approaches to improving the wear resistance of steel are described. Operational measures are also noted.

Similar content being viewed by others

REFERENCES

Shan’gin, R.V., Analysis of the operation of DT category rails at the West Siberian infrastructure direction, in Uluchshenie kachestva i uslovii ekspluatatsii rel’sov i rel’sovykh skreplenii (Improvement of the Quality and Service Conditions of Rails and Rail Brace), Yekaterinburg: Ural. Inst. Met., 2016, pp. 113–121.

Vorob’ev, I.Yu., The results of exploitation of various types of rails on the high-speed railways and mountain area of the Slyudyanskaya railway, in Uluchshenie kachestva i uslovii ekspluatatsii rel’sov i rel’sovykh skreplenii (Improvement of the Quality and Service Conditions of Rails and Rail Brace), Yekaterinburg: Ural. Inst. Met., 2017, pp. 250–263.

Shan’gin, R.V., Analysis of the operation of DT category rails at the West Siberian infrastructure direction, in Uluchshenie kachestva i uslovii ekspluatatsii rel’sov i rel’sovykh skreplenii (Improvement of the Quality and Service Conditions of Rails and Rail Brace), Yekaterinburg: Ural. Inst. Met., 2017, pp. 264–274.

Myashkin, A.A., Operation of differently heat-strengthened general-purpose rails and defects of welded joints on the Northern Railway, in Uluchshenie kachestva i uslovii ekspluatatsii rel’sov i rel’sovykh skreplenii (Improvement of the Quality and Service Conditions of Rails and Rail Brace), Yekaterinburg: Ural. Inst. Met., 2017, pp. 275–281.

Vorob’ev, I.Yu., Effective use of various categories of rails in the conditions of a mountain region, in Uluchshenie kachestva i uslovii ekspluatatsii rel’sov i rel’sovykh skreplenii (Improvement of the Quality and Service Conditions of Rails and Rail Brace), Yekaterinburg: Ural. Inst. Met., 2016, pp. 126–135.

Petrov, A.Yu., Axial loads and rail wear, Put’ Putevoe Khoz., 2003, no. 10, pp. 36–37.

Shur, E.A., How to correctly compare the wear resistance of various rails, RSP Ekspert, 2018, nos. 1–2, pp. 20–25.

Gureev, D.M., Sidorov, A.P., and Yamshchikov, S.V., Wear of friction surfaces of 40Kh steel before and after laser hardening, Trenie Iznos, 1992, vol. 13, no. 5, pp. 881–886.

Prohaska, S. and Jörg, A., Next-generation super-premium rail steels hit the tracks, Int. Railway J., 2015, Oct. 16.

Dobuzhskaya, A.B., Galitsyn, G.A., and Syreishchikova, V.I., The structure of rails with different resistance against the formation of contact fatigue defects, in Vliyanie svoistv metallicheskoi matritsy na ekspluatatsionnuyu stoikost’ rel’sov (Effect of Metal Matrix on Exploitation Resistance of Rails), Yekaterinburg: Ural. Inst. Met., 2006, pp. 64–80.

Bespalov, S.A., Destruction of metallic materials during friction, Usp. Fiz. Met., 2009, vol. 10, pp. 415–435.

Shur, E.A., Bychkova N.Ya., Markov D.P., and Kuz’min, N.N., Wear resistance of rail and wheel steels, Trenie Iznos, 1995, vol. 16, no. 1, pp. 80–91.

Pickering, F.B., Physical Metallurgy of Stainless Steel Developments, London: Applied Science, 1978.

Egorova, L.Yu., The influence of the structural state of perlite on the physicomechanical and corrosion properties of high-carbon steels, Extended Abstract of Cand. Sci. (Eng.) Dissertation, Yekaterinburg: Inst. Met. Phys., Ural Branch, Russ. Acad. Sci., 2014.

Schastlivtsev, V.M., Mirzaev, D.A., and Yakovleva, I.L., Perlit v uglerodistykh stalyakh (Perlite in Carbon Steels), Yekaterinburg: Ural. Otd., Ross. Akad. Nauk, 2006.

Gol’dshtein, M.I. and Farber, V.M., Dispersionnoe uprochnenie stali (Dispersive Hardening of Steel), Moscow: Metallurgiya, 1979.

Gavrilyuk, V.G., Raspredelenie ugleroda v stali (Distribution of Carbon in Steel), Kiev: Naukova Dumka, 1987.

ACKNOWLEDGMENTS

We thank M.A. Filippov for conducting the tests on the abrasive wear resistance at Ural Federal University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Polevoi, E.V., Yunin, G.N., Yunusov, A.M. et al. Wear Resistance of Rails. Steel Transl. 49, 492–495 (2019). https://doi.org/10.3103/S0967091219070088

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091219070088