Abstract

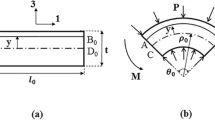

Residual stress in metals may lead to shaping defects and the failure of metal structures in prolonged operation. It may arise on account of plastic metal flow on shaping (as in forging) or slow irreversible creep at elevated temperature, under the prolonged action of loads. In viscoelastic media, it may be due to ductile strain accumulating when a body is in a deformed state for a long time. Residual stress also affects the microstructure of metals and may be present within and around crystalline grains as residual microstress, sometimes known as latent elastic stress. Residual stress is also described as eigenstress, by analogy with the eigenfunctions introduced by mathematicians to denote functions corresponding to specific parameters (eigenvalues) in a differential equation with specified boundary conditions. The concept of internal stress has been proposed as a general term for stress created by the body itself. Residual stress is then confined to cases in which the internal stress is due to irreversible deformation. Besides the creation of a favorable residual stress system, local increase in strength will be noted in forged metal disks with pronounced strain hardening, as long as the Bauschinger effect does not cancel out such benefits. In the present work, extremal values of the residual stress in a straight cylindrical steel rod (beam) are studied, in the case of flexure.

Similar content being viewed by others

References

Banabic, D., Multiscale Modeling in Sheet Metal Forming, New York: Springer-Verlag, 2016.

Banabic, D., Sheet Metal Forming Processes: Constitutive Modeling and Numerical Simulation, New York: Springer-Verlag, 2010.

Belskiy, S.M., Yankova, S., Chuprov, V.B., Bakhaev, K.V., and Stoyakin, A.O., Temperature field of stripes under hot rolling, J. Chem. Technol. Metall., 2015, vol. 50, no. 6, pp. 613–616.

Belskiy, S., Mazur, I., Lezhnev, S., and Panin, E., Distribution of linear pressure of thin-sheet rolling across strip width, J. Chem. Technol. Metall., 2016, vol. 51, no. 4, pp. 371–378.

Belskiy, S.M., Yankova, S., Mazur, I.P., and Stoyakin, A.O., Influence of the transversal displacements of metal on the camber formation of hot-rolled strip, J. Chem. Technol. Metall., 2017, vol. 52, no. 4, pp. 672–678.

Belskiy, S.M., Parameters of evaluation of shape cross section of hot-rolled steel strips. Message 1. The determination coefficient, Chern. Met., 2017, no. 10, pp. 65–70.

Chakrabarty, J., Applied Plasticity, New York: Springer-Verlag, 2010.

Tyagunov, A.G., Baryshev, E.E., Tyagunov, G.V., Mushnikov, V.S., and Tsepelev, V.S., Polytherms of the physical properties of metallic melts, Steel Transl., 2017, vol. 47, no. 4, pp. 250–256.

Tyagunov, A.G., V’yukhin, V.V., Tyagunov, G.V., Baryshev, E.E., and Akshentsev, Yu.N., Influence of the chromium concentration on structure formation in liquid chromonickel alloys, Steel Transl., 2016, vol. 46, no. 8, pp. 558–562.

Tyagunov, A.G., Vyukhin, V.V., Baryshev, E.E., Tyagunov, G.V., and Kostina, T.K., Effect of microalloying and the melting temperature on the properties of ChS70 and ChS88 alloys in the liquid and solid states, Russ. Metall. (Engl. Transl.), 2015, vol. 2015, no. 12, pp. 998–1001.

V’yukhin, V.V., Tyagunov, G.V., Baryshev, E.E., and Tsepelev, V.S., Improvement of low-alloy steel quality by forming an equilibrium melt condition, Metallurgist, 2014, vol. 58, nos. 7–8, pp. 664–668.

Tyagunov, A.G., Baryshev, E.E., V’yukhin, V.V., Kostina, T.K., and Kolotukhin, E.V., Increasing the quality of the EP902 alloy using its properties in the liquid and solid states, Russ. Metall. (Engl. Transl.), 2014, vol. 2014, no. 12, pp. 992–994.

Tyagunov, A.G., Baryshev, E.E., Tyagunov, G.V., and Mikhailov, V.B., Production of heat-resistant EP220 and EP929 alloys by high-temperature treatment of melt, Steel Transl., 2013, vol. 43, no. 9, pp. 557–560.

Tyagunov, G.V., Baryshev, E.E., and Tsepelev, V.S., Improvement of the qualitative characteristics of lowalloy steels by the formation of an equilibrium state in a melt, Russ. Metall. (Engl. Transl.), 2013, vol. 2013, no. 6, pp. 462–464.

Shinkin, V.N., Calculation of steel sheet’s curvature for its flattening in the eight-roller straightening machine, Chern. Met., 2017, no. 2, pp. 46–50.

Shinkin, V.N., Calculation of bending moments of steel sheet and support reactions under flattening on the eight-roller straightening machine, Chern. Met., 2017, no. 4, pp. 49–53.

Shinkin, V.N., Asymmetric three-roller sheet-bending systems in steel-pipe production, Steel Transl., 2017, vol. 47, no. 4, pp. 235–240.

Shinkin, V.N., Failure of large-diameter steel pipe with rolling scabs, Steel Transl., 2017, vol. 47, no. 6, pp. 363–368.

Shinkin, V.N., Simplified calculation of the bending torques of steel sheet and the roller reaction in a straightening machine, Steel Transl., 2017, vol. 47, no. 10, pp. 639–644.

Mikhailov, A.M., Zubarev, K.A., Kotel’nikov, G.I., Semin, A.E., and Grigorovich, K.V., Vaporization of the components of nickel alloys in a vacuum induction furnace, Steel Transl., 2016, vol. 46, no. 1, pp. 26–28.

Kuznetsov, M.S., Yakushev, E.V., Kulagin, S.A., Kotel’nikov, G.I., Semin, A.E., and Chegeliya, R.K., Effect of the charge composition on the nitrogen content in a metal during steelmaking in an ASF using a solid charge, Russ. Metall. (Engl. Transl.), 2011, vol. 2011, no. 12, pp. 1101–1105.

Korostelev, A.A., Kotelnikov, G.I., Semin, A.E., and Bosheskov, A.N., Analysis of HBI effect in charge on technological parameters of EAF melting, Chern. Met., 2017, no. 10, pp. 33–40.

Tursunov, N.K., Semin, A.E., and Kotelnikov, G.I., Kinetic features of desulphurization process during steel melting in induction crucible furnace, Chern. Met., 2017, no. 5, pp. 23–29.

Tursunov, N.K., Semin, A.E., and Sanokulov, E.A., Study of dephosphoration and desulphurization processes in the smelting of 20GL steel in the induction crucible furnace with consequent ladle treatment using rare earth metals, Chern. Met., 2017, no. 1, pp. 33–40.

Muhin, U., Belskij, S., and Makarov, E., Simulation of accelerated strip cooling on the hot rolling mill run-out roller table, Fratt. Integrita Strutturale, 2016, vol. 37, pp. 305–311.

Muhin, U., Belskij, S., and Makarov, E., Application of between-stand cooling in the production hot-rolled strips, Fratt. Integrita Strutturale, 2016, vol. 37, pp. 312–317.

Muhin, U. and Belskij, S., Study of the influence between the strength of antibending of working rolls on the widening during hot rolling of thin sheet metal, Fratt. Integrita Strutturale, 2016, vol. 37, pp. 318–324.

Lopatenko, A.D., Orekhov, D.M., and Semin, A.E., Improving the production of pipe steel, Steel Transl., 2016, vol. 46, no. 11, pp. 771–775.

Zubarev, K.A., Kotel’nikov, G.I., Titova, K.O., Semin, A.E., and Mikhailov, M.A., Predicting the liquidus temperature of complex nickel alloys, Steel Transl., 2016, vol. 46, no. 9, pp. 633–637.

Lim, Y., Venugopal, R., and Ulsoy, A.G., Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor Implementation, NewYork: Springer-Verlag, 2014.

Lin, J., Balint, D., and Pietrzyk, M., Microstructure Evolution in Metal Forming Processes, Amsterdam: Elsevier, 2012.

Shinkin, V.N., Calculation of technological parameters of O-forming press for manufacture of large-diameter steel pipes, CIS Iron Steel Rev., 2017, vol. 13, pp. 33–37.

Shinkin, V.N., Mathematical model of technological parameters’ calculation of flanging press and the formation criterion of corrugation defect of steel sheet’s edge, CIS Iron Steel Rev., 2017, vol. 13, pp. 44–47.

Shinkin, V.N., Springback coefficient of the main pipelines’ steel large-diameter pipes under elastoplastic bending, CIS Iron Steel Rev., 2017, vol. 14, pp. 28–33.

Shinkin, V.N., Arithmetical method of calculation of power parameters of 2N-roller straightening machine under flattening of steel sheet, CIS Iron Steel Rev., 2017, vol. 14, pp. 22–27.

Klocke, F., Manufacturing Processes 1: Cutting, NewYork: Springer-Verlag, 2011.

Klocke, F., Manufacturing Processes 4: Forming, NewYork: Springer-Verlag, 2013.

Nielsen, C.V., Zhang, W., Alves, L.M., Bay, N., and Martins, P., Modeling of Thermo-Electro-Mechanical Manufacturing Processes: Applications in Metal Forming and Resistance Welding, New York: Springer-Verlag, 2013.

Advanced Methods in Materials Processing Defects, Predeleanu, M. and Gilormini, P., Eds., Amsterdam: Elsevier, 1997, vol. 45.

Groshkova, A.L., Polulyakh, L.A., Travyanov, A.Ya., Dashevskii, V.Ya., and Yusfin, Yu.S., Phosphorus distribution between phases in smelting high-carbon ferromanganese in the blast furnace, Steel Transl., 2007, vol. 37, no. 11, pp. 904–907.

Podgorodetskii, G.S., Yusfin, Yu.S., Sazhin, A.Yu., Gorbunov, V.B., and Polulyakh, L.A., Production of generator gas from solid fuels, Steel Transl., 2015, vol. 45, no. 6, pp. 395–402.

Orelkina, O.A., Petelin, A.L., and Polulyakh, L.A., Distribution of secondary gas emissions around steel plants, Steel Transl., 2015, vol. 45, no. 11, pp. 811–814.

Polulyakh, L.A., Dashevskii, V.Ya., and Yusfin, Yu.S., Manganese-ferroalloy production from Russian manganese ore, Steel Transl., 2014, vol. 44, no. 9, pp. 617–624.

Materials Processing Defects, Studies in Applied Mechanics vol. 43, Predeleanu, M. and Ghosh, S.K., Eds., Amsterdam: Elsevier, 1995.

Rees, D., Basic Engineering Plasticity: An Introduction with Engineering and Manufacturing Applications, Oxford: Butterworth-Heinemann, 2006.

Wilko, C.E., Formability: A Review of Parameters and Processes that Control, Limit or Enhance the Formability of Sheet Metal, New York: Springer-Verlag, 2011.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.N. Shinkin, 2018, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2018, No. 11, pp. 884–890.

About this article

Cite this article

Shinkin, V.N. Elastoplastic Flexure of Round Steel Beams. 2. Residual Stress. Steel Transl. 48, 718–723 (2018). https://doi.org/10.3103/S0967091218110098

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091218110098