Abstract

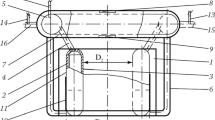

The continuous casting of steel is simulated by means of Sn–Pb alloy on two models of the mold. One of the models, which has been patented, has a closed loop for two-phase coolant circulation. The following characteristics are compared: the cooling of the two castings; the temperature of the models’ cylindrical walls; the thickness of the crust formed; the structure of the castings; and their surface quality. The results are used in simulation of the thermal processes in a model with the continuous supply of an increasing heat flux and the correction of the processes for steel casting.

Similar content being viewed by others

References

Proc. 8th Int. Conf. on Electromagnetic Processing of Materials, Cannes, France, October 12–16, 2015.

8th European Continuous Casting Conf., Graz, Austria, June 23–26, 2014.

Gosudarstvennaya programma Rossiiskoi Federatsii no. 328 ot 15.04.2014 “Razvitie promyshlennosti i povyshenie ee konkurentosposobnosti” (Governmental Program of Russian Federation No. 328 of April 15, 2014 “Industrial Development and Improvement of Competitiveness of Industry”), Moscow, 2014.

Takada, Y., Ojo, Y., Kokayashi, T., et al., Prevention of surface defects on tool steel ingot, CAMP-ISIJ, 2015, vol. 28, no. 1, p. 692 (S127).

Pierer, R., Bernhard, C., and Chimani, C., A contribution to hot tearing in the continuous casting process, Rev. Metall. (Paris), 2007, no. 2, pp. 72–83.

Hanao, M., Kawamoto, M., and Yamanaka, A., Influence of mold flux on initial solidification of hypo-peritectic steel in a continuous casting mold, J. Iron Steel Inst. Jpn., 2014, vol. 100, no. 4, pp. 581–590.

Kania, H., Nowacki, K., and Lis, T., Impact of the density of the mould powder on thickness of the layer of liquid slag in the continuous caster mould, Metallurgija, 2013, vol. 52, no. 2, pp. 204–206.

Kim, S.Y., Choi, Y.S., Hwang, J.Y., and Lee, S.H., Mold heat transfer behavior at high casting speed over 7.0 m/minute in the CEM®, POSCO, Iron Steel Technol., 2016, vol. 13, no. 7, pp. 47–56.

Raudensky, M., Tseng, A.A., Horsky, J., and Kominek, J., Recent developments of water and mist spray cooling in continuous casting of steels, Metall. Res. Technol., 2016, vol. 113, no. 5, p. 509.

Stulov, V.V., RF Patent 2601713, Byull. Izobret., 2016, no. 31.

Stulov, V.V., RF Patent 2651083, Byull. Izobret., 2018, no. 11.

Stulov, V.V., Cooling of a mold at preforming cylindrical continuous cast steel billets, J. Mach. Manuf. Reliab., 2017, vol. 40, no. 1, pp. 57–62.

Stulov, V.V., Cooling of a cylindrical crystallizer in a mold continuous casting machine, J. Mach. Manuf. Reliab., 2016, vol. 45, no. 3, pp. 266–269.

Stulov, V.V., Energy efficient cooling of a continuous casting mold, J. Mach. Manuf. Reliab., 2014, vol. 43, no. 3, pp. 429–434.

Zinov’ev, V.E., Teplofizicheskie svoistva metallov pri vysokhikh temperaturakh (Thermophysical Properties of Metals at the High Temperatures), Moscow: Metallurgiya, 1989.

Ametistov, E.V., Grigor’ev, V.A., Emtsev, B.T., et al., Teplo-i masoobmen. Teplotekhnicheskii eksperiment. Spravochnik (Heat-and Mass Transfer: Thermal Engineering Tests. Handbook), Moscow: Energoizdat, 1982.

Teplotekhnicheskii spravochnik (Thermal Engineering Handbook), Yurenev, V.N. and Lebedev, P.D., Eds., Moscow: Energiya, 1976, vol. 2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Stulov, Z.A. Tskhadaia, O.M. Shafiev, 2018, published in Stal’, 2018, No. 5, pp. 8–13.

About this article

Cite this article

Stulov, V.V., Tskhadaia, Z.A. & Shafiev, O.M. Production of Steel Castings in Cylindrical Molds. Steel Transl. 48, 307–312 (2018). https://doi.org/10.3103/S096709121805011X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709121805011X