Abstract

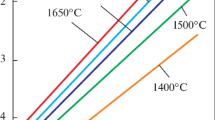

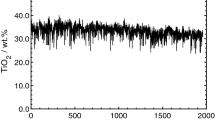

In practice, the concept of slag capacity is used to assess the distribution of elements between condensed phases. In particular, researchers determine the sulfide, phosphate, chromate, and nitride capacity of slags. In the present work, a mathematical model of the manganese capacity is derived. To that end, two equivalent forms of the manganese capacity are derived from the equilibrium constants of the redox reaction of manganese [Mn] + (1/2)O2 = (MnO). These indices reflect the manganese distribution between the metal and the slag and do not depend on the composition of the metal and the gas phase. One version takes the form CMn = KMn/γ(MnO). If we take logarithms and use the known equilibrium constant KMn of the redox reaction, we may write logCMn = 21122/T–logγ(MnO)–4.5509. To find the activity coefficient of manganese oxide, equilibrium between hot metal, cast iron, ferrosilicon, ferromanganese, and the corresponding slags is studied experimentally at various temperatures, on circulatory apparatus permitting the study of heterogeneous equilibria involving the gas phase. Using the apparatus, the change in gas volume in the reactions is monitored and automatically recorded and constant pressure is automatically maintained in the system. The attainment of equilibrium is also judged from the constancy of chemical composition of the condensed phases over time. If numerical values of γ(MnO) are available, they may be used to calculate the manganese capacity of all the slags from the equation already given. For the sake of practical convenience, the manganese capacity is written in terms of the temperature and the optical basicity λed calculated from the electron density known for elements in the periodic table: logCMn =–1.866λed + 21049/T–3.131 (R2 = 0.997). According to this equation, the manganese capacity depends only on λed and the temperature and may be used for metals and slags of practically any composition.

Similar content being viewed by others

References

Yavoiskii, V.I., Savov, P.Kh., Khuzgin, V.P., Ivanchev, I., and Erinin, Khr., Investigation of the distribution of manganese and oxygen between liquid iron and multicomponent oxide melts, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1976, no. 3, pp. 28–32.

Shchedrovitskii, V.Ya., Sarankin, V.A, et al., Slagmetal equilibrium in the processes of smelting of manganese ferroalloys, in Fiziko-khimiya i metallurgiya margantsa (Physics, Chemistry, and Metallurgy of Manganese), Moscow: Nauka, 1983, pp. 24–26.

Tolstoguzov, N.V., Distribution of silicon and manganese between metal and slag in the production of manganese alloys, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1966, no. 2, pp. 56–62.

Yakushevich, N.F., Tolstoguzov, N.V, et al., Research of the recovery of manganese oxide by carbon, in Proizvodstvo stali i ferrosplavov (Production of Steel and Ferroalloys), Novokuznetsk, 1969, no. 6, pp. 3–11.

Kim, V.A., Akberdin, A.A., and Nikolai, E.I., Installation for the study of equilibrium in metal-slag system by volumetric method, Zavod. Lab., 1982, no. 8, pp. 52–54.

Elliott, J.F., Gleiser, M., and Ramakrishna, V., Thermochemistry for Steelmaking, Reading, MA: Addison-Wesley, 1963.

Kulikov, I.S., Raskislenie splavov (Alloy Deoxidation), Moscow: Metallurgiya, 1975.

Ban’ya, S. and Dong Shim, Application of the model of regular solutions to steel-smelting slags, IX Sovetskoyaponskii simpozium po fiziko-khimicheskim osnovam metallurgicheskikh protsessov (IX Soviet–Japanese Symp. on the Physicochemical Basis of Metallurgical Processes), Moscow: Inst. Metall. Materialoved., Akad. Nauk SSSR, 1983, pp. 21–41.

Chichko, A.N., Andrianov, N.V., Chichko, A.A, et al., Experimental study of the equilibrium of phosphorus in steel smelting and possibility of its calculation, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2007, no. 10, pp. 19–22.

Shirota, Y., Katohgi, K., Klein, K., Engell, H., and Janke, D., Phosphate capacity of FeO–Fe2O3–CaO–P2O5 and FeO–Fe2O3–CaO–CaF2–P2O5 slags by levitation melting, Trans. Iron Steel Inst. Jpn., 1985, vol. 25, pp. 1132–1140.

Zhmoidin, G.I., Akberdin, A.A., and Kireeva, G.M., Sulfur-absorbent ability and optical basicity of metallurgical slags, Metally, 1996, no. 3, pp. 3–12.

Kim, A.S., Akberdin, A.A., and Konurov, U., Sorption ability of metallurgical slags, Trudy mezhdunarodnoi konferentsii “Metallurgiya XXI veka—sostoyanie i strategiya razvitiya,” 3–5 oktyabrya 2006 g. (Proc. Int. Conf. “Metallurgy of 21 Century: Status and Development Strategy,” October 3–5, 2006), Almaty, 2006, pp. 384–395.

Stadnichenko, D.V., The steel deazotation by slag mixtures with high-nitride capacity and controlled oxidation level, Cand. Sci. (Eng.) Dissertation, Moscow: Moscow Inst. Steel Alloys, 2000.

Mel’nik, S.G., Influence of the sulphide capacity of refining slags on the efficiency of desulphurization of converter steel, Metall Lit’e Ukr., 2010, no. 11, pp. 17–19.

Wagner, C., The concept of the basicity of slags, Metall. Trans. B, 1975, vol. 6, no. 3, pp. 405–409.

Kulikov, I.S., Desul’furatsiya chuguna (Desulfurization of Cast Iron), Moscow: Metallurgizdat, 1962.

Lunev, V.V. and Averin, V.V., Sera i fosfor v stali (Sulfur and Phosphorus in Steel), Moscow: Metallurgiya, 1988.

Burlakov, V.I., Desulfurization of low-silicon converter steel deoxidized by aluminum on ladle-furnace unit, Vestn. Priazovsk. Gos. Tekh. Univ., 2014, no. 28, pp. 67–74.

Zhmoidin, G.I. and Kulikov, I.S., Sulfur-absorbent capacity of silicates and aluminosilicates of calcium, in Protsessy vosstanovleniya i plavleniya zheleza (Reduction and Melting of Iron), Moscow: Nauka, 1965, pp. 62–74.

Nakamura, T., Ueda, Y., and Toguri, J., A new development of the optical basicity, J. Jpn. Inst. Met., 1986, vol. 50, no. 5, pp. 456–461.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.A. Akberdin, U.K. Konurov, R.B. Sultangaziyev, 2018, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2018, No. 1, pp. 40–45.

About this article

Cite this article

Akberdin, A.A., Konurov, U.K. & Sultangaziyev, R.B. Manganese Capacity and Optical Basicity of Metallurgical Slag. Steel Transl. 48, 7–10 (2018). https://doi.org/10.3103/S0967091218010023

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091218010023