Abstract

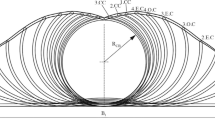

For the shaping of welded straight-seam large-diameter pipe in the TESA 1420 production line, methods are proposed for calculating the geometric parameters of the edge of the blank and the profile of the deforming tool. The edge geometry obtained on an edge-bending press is compared when using surface tools of involute and single-radius type. For tools of single-radius type, edge geometry consistent with the required shaping quality may be produced. For the edge-bending presses, a method of calculating the edge geometry in loading and unloading is outlined. The height of the bent edge, the residual radii of curvature, and the coordinates of the loading and unloading points at the external and internal edge contour of the pipe blank are determined. The coordinates of the edge formed by a tool with an involute profile are also calculated. The involute tool profile is universal on passing from one type of tool to another within a standardized group. The calculation permit conversion from an involute edge profile to a multiradial profile, followed by determination of the fixed coordinates of the points of the blank after springback. On the basis of those coordinates, the output edge geometry is estimated. Within the 1220–1420 mm standardized group, the longitudinal edge deformation for the 1220 × 10 mm type is calculated. Standardization is found to be much simpler with a single- radius tool profile. For edge-bending presses, a method of calculating the edge parameters of the pipe blank when using a tool with an involute contact profile is developed and tested in industrial conditions. Single- radius calibration of the profile of the edge-bending tool is proposed, such that fixed time coordinates are ensured. These are analogous to the coordinates with an involute punch profile. The blank’s weighted mean radius of curvature maximizes the agreement of the coordinates of the blank profile at fixed points in both approaches. (The maximum discrepancy is no more than 6–7%.)

Similar content being viewed by others

References

Samusev, S.V. and Bol’dt, V.V., Continuous profiling of welded pipe in an automatic line, Steel Transl., 2010, vol. 40, no. 1, pp. 9–11.

Samusev, S.V., Lyuskin, A.V., Romantsov, A.I., Zhigunov, K.L., and Fortunatov, A.N., Calculating tool parameters for standardized welded-pipe groups in edge-bending presses, Steel Transl., 2013, vol. 43, no. 5, pp. 236–238.

Samusev, S.V., Velichko, A.A., Lyuskin, A.V., Andreev, Yu.P., and Vorontsov, A.N., Shaping of pipe blank in the TESA-1420 line at ZAO Izhorskii Trubnyi Zavod, Steel Transl., 2009, vol. 39, no. 5, pp. 382–386.

Zhigulev, G.P., Samusev, S.V., and Fadeev, V.A., Calculation of energy-power parameters of bending process in production of welded pipes for gas pipelines, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2014, no. 7, pp. 39–42.

Fan, L., Gao, Y., Li, Q., and Xu, H., Quality control on crimping of large diameter welding pipe, Chin. J. Mech. Eng., 2012, vol. 25, no. 6, pp. 1264–1273.

Tsuru, E., Akata, J., Shinohara, K., and Uoshida, T., Numerical and experimental evaluation of formability and buckling resistance for high strength steel UOE pipe, Curr. Adv. Mater. Process., 2010, vol. 23, nos. 1–2, pp. 297–300.

Ren, Q., Li, D., Zhou, T., et al., The simulation of UOE pipe forming by three dimensional finite element methods, J. Netshape Form. Eng., 2011, vol. 3, no. 6, pp. 80–84.

Raffo, J., Toscano, R.G., Mantovano, L., and Dvorkin, E.N., Numerical model of UOE steel pipe: forming process and structural behavior, in Mecanica Computacional, Elaskar, S.A., Pilotta, E.A., and Torres, G.A., Eds., Córdoba, 2007, vol. 26, no. 10, pp. 317–333.

Kobayashi, S., Oh, S.-I., and Altan, T., Metal Forming and the Finite Element Method, New York: Oxford Univ. Press, 1989.

Herynk, M.D., Kyriakides, S., Onoufriou, A., and Yun, H.D., Effects of the UOE/UOC pipe manufacturing processes on pipe collapse pressure, Int. J. Mech. Sci., 2007, vol. 49, no. 5, pp. 533–553.

Hillenbrand, H.G., Liessem, A., Biermann, K., Heckmann, C.J., and Schwinn, V., Development and production of linepipe steels in grade X100 and X120, Seminar of X120 Grade High Performance Pipe Steels, Technical Conf., Beijing, 2005, pp. 1–11.

Il’yushin, A.A., Trudy (Research Works), Il’yushina, E.A. and Korotkina, M.R., Eds., Moscow: Fizmatlit, 2003, vol.1.

Feodos’ev, V.I., Soprotivlenie materialov: uchebnik dlya vuzov (Strength of Materials: Manual for Higher Education Institutions), Moscow: Mosk. Gos. Ttekh. Univ. im. N.E. Baumana, 2003.

Il’yushin, A.A., Plastichnost’ (Plasticity), Moscow: Gostekhizdat, 1948.

Malinin, N.N., Prikladnaya teoriya plastichnosti i polzuchesti (Applied Theory of Plasticity and Creep), Moscow: Mashinostroenie, 1968.

Rymov, V.A., Polukhin, P.I., and Potapov, I.N., Sovershenstvovanie proizvodstva svarnykh trub (Improved Production of Welded Pipes), Moscow: Metallurgiya, 1983.

Danchenko, V.N., Kolikov, A.P., and Romantsev, B.A., Tekhnologii trubnogo proizvodstva (Technologies of Pipe Production), Moscow: Intermet Inzhiniring, 2002.

Matveev, Y.M., Teoreticheskie osnovy proizvodstva svarnykh trub (Theory of Production of Welded Pipes), Moscow: Metallurgiya, 1967.

Kolikov, A.P. and Romanenko, V.P., Mashiny i agregaty trubnogo proizvodstva: uchebnoe posobie dlya vuzov (Machines and Units for Pipe Production: Manual for Higher Education Institutions), Moscow: Mosk. Inst. Stali Splavov, 1998.

Romantsev, B.A., Goncharuk, A.V., Vavilkin, N.M. and Samusev, S.V., Trubnoe proizvodstvo: uchebnik (Pipe Production: Manual), Moscow: Mosk. Inst. Stali Splavov, 2011.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © S.V. Samusev, G.P. Zhigulev, V.A. Fadeev, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2017, No. 5, pp. 369–373.

About this article

Cite this article

Samusev, S.V., Zhigulev, G.P. & Fadeev, V.A. Edge geometry of pipe blanks produced by JCOE flexure. Steel Transl. 47, 296–298 (2017). https://doi.org/10.3103/S0967091217050114

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091217050114