Abstract

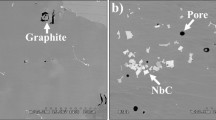

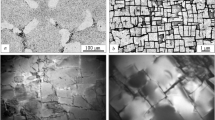

Ni3Al intermetallic alloys are produced by open inductive smelting with two different fluxes and subsequent centrifugal casting. The structure and phase composition of the alloys are investigated. Alloy samples undergo tensile tests at room temperature and elevated temperatures. The dependence of the structure and mechanical properties of the alloys on the smelting conditions is established.

Similar content being viewed by others

References

Skachkov, O.A., Prospective heat-resistant alloys based on NiAl and Ni3Al intermetallic compounds, Stal’, 2002, no. 2, pp. 74–77.

Davis, J.R., Special-purpose nickel alloys, in ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys: Introduction to Nickel and Nickel Alloys, Materials Park, OH: ASM Int., 2000, ch. 7.

Heat-resistant intermetallic alloys, April 13, 2016. http://viam.ru/review/2942.

Mengel, J., Martocci, A., Fabina, L., Petrusha, R., and Chango, R., Large-Scale Evaluation of Nickel Aluminide Rolls in a Heat-Treat Furnace at Bethlehem Steel’s (Now ISG) Burns Harbor Plate Mill, London: ISG Burns Harbor Plate, 2003.

Litye lopatki gazoturbinnykh dvigatelei: splavy, tekhnologii pokrytiya (Cast Blades of Gas Turbine Engines: Alloys and Coating Technology), Kablov, E.N., Ed., Moscow: Nauka, 2006, 2nd ed.

Kablov, E.N., Ospennikova, O.G., Sidorov, V.V., et al., Specific smelting and casting technology of the modern casting highly heat-resistant nickel alloys, Vestn. Mosk. Gos. Tekh. Univ. im. N.E. Baumana, Ser. Mashinostr., 2011, suppl. 2, pp. 68–78.

Kolobov, Yu.R., Kablov, E.N., Kozlov, E.I., et al., Struktura i svoistva intermetallidnykh materialov s nanofaznym uprochneniem (Structure and Properties of Intermetallic Materials with Nanohardening), Moscow: Mosk. Inst. Stali Splavov, 2008.

Ternary Alloys: A Comprehensive Compendium of Evaluated Constitutional Data and Phase Diagrams, Petzow, G. and Effenberg, G., Ed., New York: Wiley, 1990–1993.

Diagrammy sostoyaniya dvoinykh metallicheskikh sistem: spravochnik (State Diagrams of Binary Metal Systems: Handbook), Lyakishev, N.P., Ed., Moscow: Mashinostroenie, 1996, vol. 1; 1997, vol. 2; 2001, vol. 3, book 1; 2000, vol. 3, book 2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.A. Drozdov, O.A. Skachkov, P.O. Zhukov, T.A. Berezina, 2017, published in Stal’, 2017, No. 4, pp. 50–55.

About this article

Cite this article

Drozdov, A.A., Skachkov, O.A., Zhukov, P.O. et al. Influence of smelting on the structure and properties of an Ni3Al intermetallic alloy. Steel Transl. 47, 280–286 (2017). https://doi.org/10.3103/S0967091217040039

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091217040039