Abstract

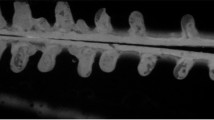

The processes at the weld joint in local heat treatment are simulated. At heating rates typical of shop conditions, the critical points of low-carbon low-alloy steel are determined for pipe of strength class K52. Local heat treatment of such pipe welded by high-frequency current is proposed to increase the impact strength and resistance to brittle failure of the weld seam at negative temperatures.

Similar content being viewed by others

References

Haga, H., Aoki, K., and Sato, T., The mechanisms of formation of weld defects in high-frequency electric resistance welding, J. Weld., 1981, vol. 60, no. 6, pp. 104–109.

Takatoshi, O., Yukinori, I., and Satoshi, I., High reliability technology of the weld zone of high-frequency electric resistant welding line-pipes, JFE Tech. Rep., 2015, no. 20, pp. 12–132.

Shin, M.H., Han, J.M., Lee, Y.S., and Kang, H.W., Study on defect formation mechanisms in ERW for API steel, Proc. 10th Int. Pipeline Conference IPC–2014, September 29–October 3, 2014, Calgary, Canada, 2014.

Golovin, G.F. and Zimin, N.V., Tekhnologiya termicheskoi obrabotki metallov s primeneniem induktsionnogo nagreva (Thermal Treatment of Metals Using Inductive Heating), Leningrad: Mashinostroenie, 1990.

Yan, P., Güngör, Ö.E., Thibaux, P., Liebeherr, M., and Bhadeshia, H.K.D.H., Tackling the toughness of steel pipes produced by high frequency induction welding and heat-treatment, J. Mater. Sci. Eng. A, 2011, vol. 528, nos. 29–30, pp. 8492–8499.

Tkachuk, M.A. and Bagmet, O.A., Determination of optimal temperature of heating during local thermal treatment of pipe weld welded by high frequency currents, Zavod. Lab. Diagn. Mater., 2015, vol. 81, no. 5, pp. 39–43.

Prokhorov, N.N., Galichenko, E.N., Medvedev, A.P., et al., RF Patent 2096485, Byull. Izobret., 1997, no. 15.

Lamukhin, A.M. and Dubinin, I.V., Startup of a casting-rolling complex and mastery of the production of high-quality rolled products for electric-welded pipes, Metallurgist, 2010, vol. 54, no. 1, pp. 19–27.

Kislitsa, V.V., Lamukhin, A.M., Isaev, O.B., et al., Foundry-rolling complex: new technologies in production of pipe rolls, Chern. Metall., 2013, no. 4, pp. 50–56.

Engel, L. and Klingele, H., Rasterelektronenmikroskopische Untersuchungen von Metallschäden, Leipzig: Hanser, 1982.

Lin, A.F., Mechanics and Mechanisms of Fracture: An Introduction, Materials Park, OH: ASTM Int., 2005.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.A. Tkachuk, O.A. Bagmet, P.P. Stepanov, 2016, published in Stal’, 2016, No. 3, pp. 54–59.

About this article

Cite this article

Tkachuk, M.A., Bagmet, O.A. & Stepanov, P.P. Local heat treatment of weld seams in moderate-diameter pipe produced by high-frequency current. Steel Transl. 46, 224–229 (2016). https://doi.org/10.3103/S0967091216030141

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091216030141