Abstract

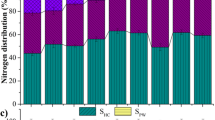

Municipal solid waste (MSW) disposal is one of the main issues towards sustainable development. Various technologies are studied to solve it. Hydrothermal carbonization (HTC) is an appropriate technology selection to reduce the waste volume primarily and to utilize MSW as the energy source because of its high the calorific value inside. This paper describes the potential of hydrochar production of raw materials in the provinces of East Java, Indonesia. The hydrochar production can be used as a secondary char and for electrical generation if it is combined with gasification process. The waste material affected the quality of combustion and calorific value to the product. The proximate and ultimate analysis using ASTM methods was conducted to analyze the characteristics of hydrochar. The influences of the HTC temperatures at saturated pressure (220°C, 23 bar) and variations of the feedstock moisture content (20–60%) were studied using a simulation of HTC process. The average calorific value of hydrochar is increased 32% of waste materials, 70% hydrochar yield, and 84% energy efficiency. This value indicates that the HTC process can produce hydrochar, moreover it reduced the mass of waste materials, also increased the energy content of products and the energy efficiency is a potential of energy generation from waste materials in an area.

Similar content being viewed by others

REFERENCES

Mayer, F., Bhandari, R., and Gath, S., Sci. Total Environ., 2019, vol. 672, p. 708. https://doi.org/10.1016/j.scitotenv.2019.03.449

Násner, A.M.L., Lora, E.E.S., Palacio, J.C.E., Rocha, M.H., Restrepo, J.C., Venturini, O.J., and Ratner, A., Waste Manag., 2017, vol. 69, p. 187. https://doi.org/10.1016/j.wasman.2017.08.006

Effat, H.A. and Hegazy, M.N., Egypt. J. Remote Sens. Sp. Sci., 2012, vol. 15, no. 2, p. 125. https://doi.org/10.1016/j.ejrs.2012.09.002

Zheng, X., Chen, W., Ying, Z., Huang, J., Ji, S., and Wang, B., Int. J. Hydrogen Energy, 2019, vol. 44, no. 21, p. 10374. https://doi.org/10.1016/j.ijhydene.2019.02.200

Gai, C., Chen, M., Liu, T., Peng, N., and Liu, Z., Energy, 2016, vol. 113, p. 957. https://doi.org/10.1016/j.energy.2016.07.129

Gai, C., Guo, Y., Liu, T., Peng, N., and Liu, Z., Int. J. Hydrogen Energy, 2016, vol. 41, no. 5, p. 3363. https://doi.org/10.1016/j.ijhydene.2015.12.188

Kamble, A.D., Saxena, V.K., Chavan, P.D., and Mendhe, V.A., Int. J. Min. Sci. Technol., 2019, vol. 29, no. 2, p. 171. https://doi.org/10.1016/j.ijmst.2018.03.011

Krysanova, K., Krylova, A., and Zaichenko, V., Fuel, 2019, vol. 256, p. 115929. https://doi.org/10.1016/j.fuel.2019.115929

Zheng, C., Ma, X., Yao, Z., and Chen, X., Biores. Technol., 2019, vol. 285, p. 121347. https://doi.org/10.1016/j.biortech.2019.121347

Lee, J., Sohn, D., Lee, K., and Park, K.Y., Chemosphere, 2019, vol. 230, p. 157. https://doi.org/10.1016/j.chemosphere.2019.05.066

Liu, T., Lang, Q., Xia, Y., Chen, Z., Li, D., Ma, J., Gai, C., and Liu, Z., Fuel, 2019. https://doi.org/10.1016/j.fuel.2019.01.035

Zheng, C., Ma, X., Yao, Z., and Chen, X., Biores., Technol., 2019. https://doi.org/10.1016/j.biortech.2019.121347

McGaughy, K. and Toufiq, Reza M., Biomass Convers. Biorefinery, 2018, vol. 8, no. 2, p. 283. https://doi.org/10.1007/s13399-017-0276-4

Khan, T.A., Saud, A.S., Jamari, S.S., Rahim, M.H.A., Park, J.-W., and Kim, H.-J., Biomass Bioenergy, 2019. https://doi.org/10.1016/j.biombioe.2019.105384

Heidari, M., Dutta, A., Acharya, B., and Mahmud, S., J. Energy Inst., 2018, p. 1. https://doi.org/10.1016/j.joei.2018.12.003

Liu, Z. and Balasubramanian, R., Appl. Energy, 2014, vol. 114, p. 857. https://doi.org/10.1016/j.apenergy.2013.06.027

Erlach, B., Harder, B., and Tsatsaronis, G., Proc. 24th Int. Conf. Effic. Cost, Optim. Simul. Environ. Impact Energy Syst. ECOS 2011, 2011, vol. 45, no. 1, p. 3642. https://doi.org/10.1016/j.energy.2012.01.057

Boumanchar, I., Chhiti, Y., M’hamdi, Alaoui F.E., El Ouinani, A., Sahibed-Dine, A., Bentiss, F., Jama, C., and Bensitel, M., Waste Manag., 2017, vol. 61, p. 78. https://doi.org/10.1016/j.wasman.2016.11.012

Gao, L., Volpe, M., Lucian, M., Fiori, L., and Goldfarb, J.L., Energy Convers. Manag., 2019. https://doi.org/10.1016/j.enconman.2018.12.009

Lucian, M., Volpe, M., Gao, L., Piro, G., Goldfarb, J.L., and Fiori, L., Fuel, 2018. https://doi.org/10.1016/j.fuel.2018.06.060

Lin, Y., Ma, X., Peng, X., and Yu, Z., Biores. Technol., 2017. https://doi.org/10.1016/j.biortech.2017.06.117

Kim, D., Park, K.Y., and Yoshikawa, K., Eng. Appl. Biochar., 2017. https://doi.org/10.5772/intechopen.68221

Reza, M.T., Uddin, M.H., Lynam, J.G., and Coronella, C.J., Biomass Bioenergy, 2014, vol. 63, p. 229. https://doi.org/10.1016/j.biombioe.2014.01.038

Zhao, P., Shen, Y., Ge, S., Chen, Z., and Yoshikawa, K., Appl. Energy, 2014, vol. 131, p. 345. https://doi.org/10.1016/j.apenergy.2014.06.038

Mäkelä, M., Forsberg, J., Söderberg, C., Larsson, S.H., and Dahl, O., Biores. Technol., 2018, vol. 263, p. 654. https://doi.org/10.1016/j.biortech.2018.05.044

Javadzadeh, Y. and Hamedeyaz, S., Trends Helicobacter pylori Infect., 2014, p. 13. https://doi.org/10.5772/57353

Zhu, G., Yang, L., Gao, Y., Xu, J., Chen, H., Zhu, Y., Wang, Y., Liao, C., Lu, C., and Zhu, C., Fuel, 2019, vol. 244, p. 479. https://doi.org/10.1016/j.fuel.2019.02.039

Steurer, E. and Ardissone, G., Energy Procedia, 2015, vol. 79, p. 47. https://doi.org/10.1016/j.egypro.2015.11.473

Tumuluru, J.S., Biomass Preprocessing and Pretreatments for Production of Biofuels, 2018.https://doi.org/10.1201/9781315153735

Basu, P., Biomass Gasification Design Handbook, Elsevier, 2010, p. 27. https://doi.org/10.1016/b978-0-12-374988-8.00002-7

Naderi, M. and Vesali-Naseh, M., Biomass Convers. Biorefinery, 2019. https://doi.org/10.1007/s13399-019-00513-2

Zornoza, R., Moreno-Barriga, F., Acosta, J.A., Mu-ñoz, M.A., and Faz, A., Chemosphere, 2016, vol. 144, p. 122. https://doi.org/10.1016/j.chemosphere.2015.08.046

Zhang, X., Zhang, L., and Li, A., J. Environ. Manage., 2017, vol. 201, p. 52. https://doi.org/10.1016/j.jenvman.2017.06.018

Khandelwal, H., Dhar, H., Thalla, A.K., and Kumar, S., J. Clean. Prod., 2019, vol. 209, p. 630. https://doi.org/10.1016/j.jclepro.2018.10.233

Dong, M., Mao, X., Gonzalez, J.J., Lu, J., and Russo, R.E., J. Anal. At. Spectrom., 2012, vol. 27, no. 12, p. 2066. https://doi.org/10.1039/c2ja30222e

Vassilev, S.V., Vassileva, C.G., and Vassilev, V.S., Fuel, 2015, vol. 158, p. 330. https://doi.org/10.1016/j.fuel.2015.05.050

Vassilev, S.V., Vassileva, C.G., Song, Y.C., Li, W.Y., and Feng, J., Fuel, 2017, vol. 208, p. 377. https://doi.org/10.1016/j.fuel.2017.07.036

ACKNOWLEDGMENTS

We would like to express our sincere thanks, gratitude and appreciations to LPPM ITS, for funding the current research under the scheme of Pascasarjana Research Grant 2019. We also would like to extend our appereciations to all members of Energy Engineering and Environmental Conditioning Laboratory, Department of Engineering Physics ITS for their enormous contributions to this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The data that support the findings of this study are available from the corresponding author upon reasonable request.

About this article

Cite this article

Hantoro, R., Septyaningrum, E., Siswanto, B.B. et al. Hydrochar Production through the HTC Process: Case Study of Municipal Solid Waste Samples in East Java, Indonesia. Solid Fuel Chem. 54, 418–426 (2020). https://doi.org/10.3103/S036152192006004X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S036152192006004X