Abstract—

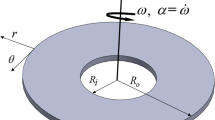

An analysis properties of the constitutive relations of the theory of deformation for physically nonlinear materials with properties depending on the type of stress state is carried out. These relations take into account two forms of nonlinearity, one of them is associated with the nonlinearity of the deformation diagrams and another one is associated with the change in these diagrams depending on the loading conditions. The distributions of stresses and strains in a rotating disk made of a material with properties sensitive to the type of stress state are investigated and a comparison with the results of calculations for a material with properties invariant to the form of external forces is performed.

Similar content being viewed by others

REFERENCES

V. S. Deshpande, and Fleck N.A. “High strain rate compressive behaviour of aluminium alloy foams,” Int. J. Impact Eng. 24, 277–298 (2000).

V. S. Deshpande and N. A. Fleck, “Multi-axial yield behaviour of polymer foams,” Acta Mater. 49, 1859–1866 (2001).

I. Sridhar and N. A. Fleck, “The multiaxial yield behaviour of an aluminium alloy foam,” J. Mater. Sci. 40, 4005–4008 (2005).

L. H. Han, J. A. Elliott, A. C. Bentham, et al., “A modified Drucker-Prager Cap model for die compaction simulation of pharmaceutical powders,” Int. J. Solid Struct. 45, 3088–3106 (2008).

O. Cazacu and J. Stewart, “Analytic plastic potential for porous aggregates with matrix exhibiting tensioncompression asymmetry,” J. Mech. Phys. Solids 57, 325–341 (2009).

S. Pietrusczac and Z. Mroz, “Formulation of anisotropic failure criteria incorporating a microstructure tensor,” Comp. Geotech. 26, 105–112 (2000).

Z. Gao, J. Zhao and Y. Yao, “A generalized anisotropic failure criterion for geomaterials,” Int. J. Solid Struct. 47, 3166–3185 (2010).

F. Barlat, Y. Maeda, K. Chung, et al., “Yield function development for aluminium alloy sheets,” J. Mech. Phys. Solids 45, 1727–1763 (1997).

S. Soare and F. Barlat, “Convex polynomial yield functions,” J. Mech. Phys. Solids 58, 1804–1818 (2010).

D. C. C. Lam, F. Yang, A. C. M. Chong, et al., “Experiments and theory in strain gradient Elasticity,” J. Mech. Phys. Solids 51, 1477–1508 (2003).

A. W. Mc Farland and J. S. Colton, “Role of material microstructure in plate stiffness with relevance to microcantilever sensors,” J. Micromech. Microeng. 15, 1060–1067 (2005).

B. V. Sankar, “An elasticity solution for functionally graded beams,” Compos. Sci. Technol. 61, 689-696 (2001).

A. Chakraborty, S. Gopalakrishnan, and J.N. Reddy, “A new beam finite element for the analysis of functionally graded materials,” Int. J. Mech. Sci. 45, 519–539 (2003).

Y. Q. Fu, H. J. Du, and S. Zhang, “Functionally graded TiN/TiNi shape memory alloy films,” Mater. Lett. 57, 2995–2999 (2003).

Z. Lee, C. Ophus, L.M. Fischer, Nelson, et al., “Metallic NEMS components fabricated from nanocomposite Al–Mo films,” Nanotechn. 17, 3063–3070 (2006).

E. V. Lomakin, B. N. Fedulov, and A. M. Melnikov, “Constitutive models for anisotropic materials susceptible to loading conditions,” in Mechanics and Model-Based Control of Advanced Engineering Systems (Springer-Verlag, Wien, 2014), pp. 209–216.

E. V. Lomakin and B. N. Fedulov, “Nonlinear anisotropic elasticity for laminate composites,” Meccanica 50 (6), 1527–1535 (2015).

S. Liu and H. Qiao, “Topology optimization of continuum structures with different tensile and compressive properties in bridge layout design,” Struct. Multidiscip. Optim. 43, 369–380 (2011).

K. Cai, Z. J. Luo, and Q. H. Qin, “Topology optimization of bi-modulus structures using the concept of bone remodeling,” Eng. Comp. 31, 1361–1378 (2014).

E. V. Lomakin and M. P. Tretyakov, “Fracture properties of graphite materials and analysis of crack growth under bending conditions,” Meccanica 51 (10), 2353–2364 (2016).

G. Medri, “A nonlinear elastic model for isotropic materials with different behavior in tension and compression,” Trans. ASME J. Eng. Mat. Techn. 104, 26–28 (1982).

S. A. Ambartsumyan, Different-Modulus Elasticity Theory (Nauka, Moscow, 1982) [in Russian].

R. M. Jones, “Buckling of circular cylindrical shells with different moduli in tension and compression,” AIAA J. 9, 53–61 (1971).

R. M. Jones, “Buckling of stiffened multilayered circular cylindrical shells with different orthotropic moduli in tension and compression,” AIAA J. 9, 917–923 (1971).

B. P. Patel, K. Khan, and Y. Nath, “A new constitutive model for bimodular laminated structures: Application to free vibrations of conical/cylindrical panels,” Compos. Struct. 110, 183–191 (2014).

Z. M. Ye, H. R. Yu, and W. J. Yao, “A new elasticity and finite element formulation for different Young’s modulus when tension and compression loading,” J. Shanghai Univ. 5, 89–92 (2001).

K. Vijayakumar and K. P. Rao, “Stress–strain relation for composites with different stiffnesses in tension and compression – a new model,” Int. J. Comp. Mech. 1, 167–175 (1987).

E. V. Lomakin, “Difference in the modules of composite materials,” Mech. Compos. Mater. 17 (1), 18–24 (1981).

E. V. Lomakin, “Constitutive relations of deformation theory for dilatant media,” Mech. Solids 26 (6), 66–75 (1991).

T. A. Belyakova and E. V. Lomakin, “Elastoplastic deformation of a dilatant medium subjected to a plane stress state near a crack tip,” Mech. Solids 39 (1), 81–87 (2004).

Funding

This study was supported by the Russian Science Foundation (grant 20-11-20230).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. A. Borimova

About this article

Cite this article

Lomakin, E.V., Shchendrigina, O.P. Stresses and Strains in a Disk of Physically Nonlinear Material with Stress State Dependent Properties. Mech. Solids 55, 475–481 (2020). https://doi.org/10.3103/S0025654420040081

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654420040081