Abstract

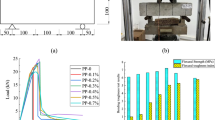

Tension stiffening is an essential effect that influences the behaviour of concrete structures under serviceability conditions, mainly regarding crack control and deflection behaviour. Serviceability conditions can be studied experimentally by running the so-called uniaxial tensile test. This paper reports an extensive experimental research conducted to study the tensile behaviour of reinforced Ultra-High Performance Fibre-Reinforced Concrete (R-UHPFRC) under service conditions by uniaxial tensile testing. The parameters studied were the reinforcement ratio and the steel fibre content in a experimental programme including 36 specimens. Special testing equipment and methodology to measure the post-cracking deformation of R-UHPFRC ties were developed, and special attention was paid to the shrinkage effect. The tensile elements’ axial stiffness was approximately parallel to the bare bar response after microcracking formation showing a full tension-stiffening response. The average tensile capacity of the reinforced elements (tension stiffening response) was achieved. Concrete’s contribution in the R-UHPFRC ties with the tensile properties deriving from four-point bending tests (4PBTs) on non-reinforced UHPFRC specimens was also compared. The experimental results revealed a slight increase in concrete’s contribution with the higher reinforcement ratio. Moreover, the concrete’s contribution in the tensile elements was higher than the characteristic tensile properties deriving from 4PBTs.

Similar content being viewed by others

Code availability

Not applicable.

References

Burns C (2012) Serviceability analysis of reinforced concrete based on the tension chord model, PhD thesis no. 19979, Institute of Structural Engineering, Swiss Federal Institute of Technology, Zurich, Switzerland

Honfi D (2013) Design for Serviceability-A probabilistic approach. Lund University, Sweden

Sahamitmongkol R, Kishi T (2011) Tension stiffening effect and bonding characteristics of chemically prestressed concrete under tension. Mater Struct 44(2):455–474

Gribniak V et al (2015) Stochastic tension-stiffening approach for the solution of serviceability problems in reinforced concrete: Constitutive modeling. Comput-Aided Civil Infrastruct Eng 30(9):684–702

Muhamad R et al (2012) The tension stiffening mechanism in reinforced concrete prisms. Adv Struct Eng 15(12):2053–2069

Model Code 2010 (2012), Final Complete Draft, Fib Bull: No.65 and 66, March 2012-ISBN 978-2-88394-105-2 and April 2012-ISBN 978-2-88394-106-9

AFGC S (2002) Bétons fibrés à ultra-hautes performances–Recommandations provisoires. AFGC, France

Committee JC (2008) Recommendations for design and construction of high performance fiber reinforced cement composites with multiple fine cracks. Japan Society of Civil Engineers, Tokyo, Japan

Cahier Technique SIA 2052 (2014) Béton fibré ultra-performant (BFUP)-Matériaux, dimensionnement et exécution. Projet

Belarbi A, Hsu TT (1994) Constitutive laws of concrete in tension and reinforcing bars stiffened by concrete. Structural Journal 91(4):465–474

Yankelevsky DZ, Jabareen M, Abutbul AD (2008) One-dimensional analysis of tension stiffening in reinforced concrete with discrete cracks. Eng Struct 30(1):206–217

Stramandinoli RS, La Rovere HL (2008) An efficient tension-stiffening model for nonlinear analysis of reinforced concrete members. Eng Struct 30(7):2069–2080

Collins MP, Mitchell D (1991) Prestressed concrete structures, vol 9. Prentice Hall Englewood Cliffs, NJ

Kaklauskas G (2001) Integral constitutive model for deformational analysis of flexural reinforced concrete members. Statyba 7(1):3–9

Hsu TT (2017) Unified theory of reinforced concrete. Routledge, UK

Fields K, Bischoff PH (2004) Tension stiffening and cracking of high-strength reinforced concrete tension members. Structural Journal 101(4):447–456

Patel K, Chaudhary S, Nagpal A (2016) A tension stiffening model for analysis of RC flexural members under service load. Comput Concrete 17(1):29–51

Lee SC, Cho JY and Vecchio FJ (2013) Tension-Stiffening Model for Steel Fiber-Reinforced Concrete Containing Conventional Reinforcement. ACI Structural Journal 110(4)

Bischoff PH (2003) Tension stiffening and cracking of steel fiber-reinforced concrete. J Mater Civ Eng 15(2):174–182

Amin A, Foster SJ, Watts M (2016) Modelling the tension stiffening effect in SFR-RC. Mag Concrete Res 68(7):339–352

Deluce JR, Vecchio FJ (2013) Cracking Behavior of Steel Fiber-Reinforced Concrete Members Containing Conventional Reinforcement. ACI Struct J 110(3):481–490

Bernardi P et al (2016) Experimental and numerical study on cracking process in RC and R/FRC ties. Mater Struct 49(1–2):261–277

Baby F et al (2013) UHPFRC tensile behavior characterization: inverse analysis of four-point bending test results. Mater Struct 46(8):1337–1354

Lee S-C, Kim H-B, Joh C (2017) Inverse Analysis of UHPFRC Beams with a Notch to Evaluate Tensile Behavior. Advances in Materials Science and Engineering 2017:1–10

Baby F et al (2013) Identification of UHPFRC tensile behaviour: methodology based on bending tests. UHPFRC 2013-International Symposium on Ultra-High Performance Fibre-Reinforced Concrete: 649–658

Baby F et al (2012) Proposed flexural test method and associated inverse analysis for ultra-high-performance fiber-reinforced concrete. ACI Mater J 109(5):545

López JÁ et al (2015) An inverse analysis method based on deflection to curvature transformation to determine the tensile properties of UHPFRC. Mater Struct 48(11):3703–3718

López JÁ (2017) Characterisation of The Tensile Behaviour of UHPFRC by Means of Four-Point Bending Tests. PhD Thesis, Universitat Politècnica de València

Khorami M, Navarro-Gregori J, Serna P (2020) Experimental methodology on the serviceability behaviour of reinforced ultra-high performance fibre reinforced concrete tensile elements. Strain 56(5):e12361

Khorami M et al (2019) A testing method for studying the serviceability behavior of reinforced UHPFRC tensile ties. in IOP Conference Series: Materials Science and Engineering. IOP Conference Series 596:12–22

Lee N, Chisholm D (2005) Reactive Powder Concrete, Study Report SR 146. Ltd, Judgeford, New Zealand

Beigi MH et al (2013) An experimental survey on combined effects of fibers and nanosilica on the mechanical, rheological, and durability properties of self-compacting concrete. Mater Des 50:1019–1029

Li VC (2002) Large volume, high-performance applications of fibers in civil engineering. J Appl Polym Sci 83(3):660–686

Edgington J (1973) Steel fibre reinforced concrete. University of Surrey, Guildford

López J et al (2015) Comparison between inverse analysis procedure results and experimental measurements obtained from UHPFRC Four-Point Bending Tests. in Seventh International RILEM Conference on High Performance Fiber Reinforced Cement Composites (HPFRCC7): 185–192

Löfgren I (2005) Fibre-reinforced Concrete for Industrial Construction-a fracture mechanics approach to material testing and structural analysis. Chalmers University of Technology, Gothenburg

Afroughsabet V, Biolzi L, Ozbakkaloglu T (2016) High-performance fiber-reinforced concrete: a review. J Mater Sci 51(14):6517–6551

Buttignol TET, Sousa J, Bittencourt T (2017) Ultra High-Performance Fiber-Reinforced Concrete (UHPFRC): a review of material properties and design procedures. Revista IBRACON de estruturas e materiais 10(4):957–971

Fehling E et al (2014) Ultra-high performance concrete UHPC: Fundamentals, design, examples. Wiley, NY

Makita T, Brühwiler E (2014) Tensile fatigue behaviour of Ultra-High Performance Fibre Reinforced Concrete combined with steel rebars (R-UHPFRC). Int J Fatigue 59:145–152

Rauch M and Sigrist V (2010) Dimensioning of Structures made of UHPFRC. in IABSE Symposium Report. 34th International Association for Bridge and Structural Engineering 97(34):39–46

Sigrist V and Rauch M (2008) Deformation behavior of reinforced UHPFRC elements in tension. Anonymous Tailor Made Concrete Structures. CRC Press: 405–410

Redaelli D (2006) Testing of reinforced high performance fibre concrete members in tension. in Proceedings of the 6th Int. Ph. D. Symposium in Civil Engineering, Zurich 2006. 2006. Proceedings of the 6th Int. Ph. D. Symposium in Civil Engineering, Zurich

Institution BS (2004) Eurocode 2: Design of concrete structures: Part 1–1: General rules and rules for buildings. British Standards Institution, UK

Gribniak V, Kaklauskas G and Bačinskas D (2007) State-of-art review of shrinkage effect on cracking and deformations of concrete bridge elements. The Baltic Journal of Road & Bridge Engineering 2(4):183-193

Torst H (1967) Auswirkungen des superpositionsprinzips auf kriech-und relaxationsprobleme bei beton und spannbeton. Beton-und stahlbetonbau 10(230–238):261–269

Bazant Z (1972) Predictions of concrete effects using age adjusted effective modulus method. J Am Concrete Institute 69:212–217

AFGC (2013) Ultra high performance fibre-reinforced concretes, recommendations. Documents scientifiques et techniques, Paris

Gowripalan N, Gilbert R (2000) Design guidelines for RPC prestressed concrete beams. School of Civil and Environmental Engineering, University of New South Wales, Sydney, Australia

Ostergaard L, Walter R and Olesen J (2005) Method for determination of tensile properties of engineered cementitious composites (ECC). Proceedings of ConMat'05, Vancouver, Canada

Kanakubo T (2006) Tensile characteristics evaluation method for ductile fiber-reinforced cementitious composites. J Adv Concrete Technol 4(1):3–17

Acknowledgements

This study forms part of Project BIA2016-78460-C3-1-R, supported by the Ministry of Economy and Competitiveness of Spain.

Funding

Project BIA2016-78460-C3-1-R, supported by the Ministry of Economy and Competitiveness of Spain.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

Not applicable.

Availability of data Material

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khorami, M., Navarro-Gregori, J. & Serna, P. Tensile behaviour of reinforced UHPFRC elements under serviceability conditions. Mater Struct 54, 43 (2021). https://doi.org/10.1617/s11527-021-01630-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01630-z