Abstract

Calcium leaching is an important durability problem for cement asphalt (CA) mortar used in ballastless slab track which is under the coupled action of train-induced dynamic load and rainwater erosion. In this paper, a model based on the calcium mass conservation and the thermodynamic equilibrium of calcium was developed to describe the calcium leaching of CA paste in both deionized water and ammonium nitrate solution. In this model, the spatial–temporal distribution of solid calcium content in skeleton, porosity and diffusivity, which are directly or indirectly relevant to the calcium concentration in pore solution, were considered. Finite difference method was utilized to solve this model, and a three layer Crank–Nicolson differential scheme was applied to improve the stability. The model was experimentally verified using the Ca/Si molar ratio in solid and the calcium leaching rate characterized by SEM–EDX and potentiometric titration respectively. It was found that asphalt content does not change the spatial distribution of solid calcium in CA paste. Asphalt affects the leaching rate by reducing solid calcium concentration and changing the activation energy of micro-pore wall. Accelerating factors by ammonium nitrate solution were experimentally determined and predicted by the model.

Similar content being viewed by others

References

Esveld C (2003) Recent developments in slab track. Eur Railw Rev 9:81–85

Esveld C (2001) Modern railway track. MRT-Productions, Zaltbommel, pp 231–274

Jin SH, Chen XF (2004) Technical characteristics of construction of Qinhuangdao–Shenyang passenger special line and the inspiration for high-speed railway. Eng Sci 2(1):26–34

Deng DH, Xin XZ (2013) Construction technology for cement asphalt mortar of CRTS II ballastless slab track. China Railway Press, Beijing (In Chinese)

Fang L, Yuan Q, Deng DH et al (2017) Effect of mix parameters on the dynamic mechanical properties of cement asphalt mortar. J Mater Civ Eng 29(8):04017080–04017081

Tian Q, Yuan Q, Fang L et al (2017) Estimation of elastic modulus of cement asphalt binder with high content of asphalt. Constr Build Mater 133:98–106

Peng JW, Deng DH, Yuan Q et al (2014) Study of the rheological behavior of fresh cement emulsified asphalt paste. Constr Build Mater 66:348–355

Wang Y, Yuan Q, Deng DH et al (2017) Measuring the pore structure of cement asphalt mortar by nuclear magnetic resonance. Constr Build Mater 137:450–458

Wang Y, Yuan Q, Deng DH et al (2017) Modeling compressive strength of cement asphalt composite based on pore size distribution. Constr Build Mater 150:714–722

Galvin P, Romero A, Dominguez J (2010) Vibration induced by HST passage on ballast and non-ballast tracks. Soil Dyn Earthq Eng 30:862–873

Adenot F, Buil M (1992) Modelling of the corrosion of the cement paste by deionized water. Cem Concr Res 22:489–496

Buil M (1992) A model of the attack of pure water or undersaturated lime solution on cement. ASTM STP 1123:227–241

Kuhl D, Bangert F, Meschke G (2004) Coupled chemo-mechanical deterioration of cementitious materials. Part I: modeling. Int J Solids Struct 41:15–40

Carde C, Francios R (1999) Modelling the loss strength and porosity increase due to the leaching of cement paste. Cem Concr Compos 21:181–188

Carde C, Francios R (1996) Leaching of both calcium hydrate and C–S–H from paste: modeling the mechanical behavior. Cem Concr Res 26:1257–1268

Gerard B, Bellege CL, Bernard Q (2002) Simplified modelling of calcium leaching of concrete in various enviroments. Mater Struct 35:632–640

Gerard B (1998) Coupled diffusion damage modelling and the implications on failure due to strain localization. Int J Solids Struct 35:4107–4120

Torrenti JM, Mainguy M, Adenot F et al (1998) Modelling of leaching in concrete. In: Computational modelling of concrete structures, Euro-C 1998 proceedings. A.A. Balkema Publishers, Rotterdam, pp 531–538

Ulm FJ, Torrenti JM, Adenot F (1999) Chemoporoplasticity of calcium leaching in concrete. J Eng Mech ASCE 15(10):1200–1211

Ryu J, Otsuki N, Minagawa H (2002) Long-term forecast of Ca leaching from mortar and associated degeneration. Cem Concr Res 32:1539–1544

Alonso C, Castellote M et al (2006) Ground water leaching resistance of high and ultra high performance concretes in relation to the testing convection regime. Cem Concr Res 36:1583–1594

Heukamp FH, Ulm FJ, Germaine JT (2012) Mechanical properties of calcium leached cement paste Triaxial stress states and the influences of the pore pressures. Cem Concr Res 42:686–699

Kamali S, Gerard B, Moranville M (2008) Material and environmental parameter effects on the leaching of cement pastes: experiments and modeling. Cem Concr Res 38:575–585

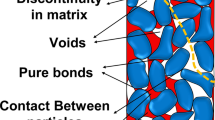

Deng DH, Tian Q, Liu ZQ et al (2014) Physical structure of hardened cement asphalt paste for slab track of high-speed railway. Sci China Ser E-Tech Sci 44(7):661–671 (In Chinese)

Nakarai K, Ishida T, Maekawa K (2006) Modeling of calcium leaching from cement hydrates coupled with micro-pore formation. J Adv Concr Technol 4(3):395–407

China Railway Ministry (2008) Passenger dedicated line railway provisional technical conditions CRTS I type of slab track emulsified asphalt cement mortar

China Railway Ministry (2008) Passenger dedicated line railway provisional technical conditions CRTS II type of slab track emulsified asphalt cement mortar

Lesueur D (2009) The colloidal structure of bitumen: consequences on the rheology and on the mechanisms of bitumen modification. Adv Colloid Interface 145:42–82

Harris AW, Manning MC, Tearle WM (2002) Testing of models of the dissolution of cements-leaching of synthetic C–S–H gels. Cem Concr Res 32:731–746

Perlot C et al (2013) Diffusivity evolution under decalcification: influence of aggregate natures and cement type. Mater Struct 46:787–801

Wan KS, Li T, Sun W (2013) Experimental and modelling research of the accelerated calcium leaching of cement paste in ammonium nitrate solution. Constr Build Mater 40:832–846

Haga K, Sutou S, Hironaga M (2005) Effects of porosity in leaching of Ca from hardened ordinary Portland cement paste. Cem Concr Res 35:1764–1775

Garboczi EJ, Bentz DP (1992) Computer simulation of the diffusivity of cement-based materials. J Mater Sci 27:2083–2092

Snyder KA, Clifton JR (1995) A computer program for modeling degradation of underground low level waste concrete vaults. NISTIR 5612, US Department of Commerce

Marchand J, Bentz DP (2001) Influence of calcium hydroxide dissolution on the transport properties of hydrated cement systems. In: Materials science of concrete, special volume: calcium hydroxide in concrete, pp 113–129

Sato H, Yui M, Yoshikawa H (1995) Diffusion behavior for Se and Zr in sodium–bentonite. In: Proceedings of materials research society symposium, vol 353, pp 269–276

McCarter WJ, Starrs G, Chrisp TM (2000) Diffusion kinetics in cementitious binders. J Mater Sci Lett 19:1279–1280

Greenberg SA, Chang TN (1965) Investigation of the colloidal hydrated calcium silicates. II: solubility relationships in the calcium oxide–silica–water system at 25 °C. J Phys Chem 69:182–188

Acknowledgements

Financial support by the National Natural Science Foundation of China (Grants 51478476 and 51778629) and the National Basic Research Program of China (“973” Program) (Grant 2013CB036201) are highly appreciated. The authors would like to thank Dr. Lei Fang for his help with the tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Yuan, Q. & Deng, D. Modelling calcium leaching kinetics of cement asphalt paste. Mater Struct 51, 133 (2018). https://doi.org/10.1617/s11527-018-1261-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-018-1261-5