Abstract

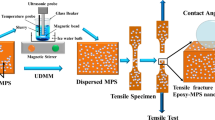

As the most important thermoplastic and thermosetting modifiers, styrene–butadiene–styrene triblock copolymer (SBS) and epoxy resin have been widely applied in asphalt modifications. In this paper, epoxy SBS-modified asphalts (ESBAs) were prepared with epoxy monomer, curing agent and SBS-modified asphalts (SBAs) with various styrene–butadiene structures, which in turn were subjected to laser scanning confocal microscopy (LSCM), viscous measurements, thermal analysis and tensile tests. The LSCM results revealed that both polymer-rich phase and fluorescent particle-rich phase were observed in the asphalt matrix. Moreover, the number of SBS particles in SBAs increased with the increase of styrene contents. The presence of SBS decreased the size of dispersed domains in the continuous epoxy phase of the neat epoxy asphalt binder (EAB). For ESBAs, a double phase separation occurred between SBA and epoxy in the continuous epoxy phase and between asphalt and SBS in the dispersed SBA phase. Both number and size of SBS domains in the dispersed SBA phase of ESBAs increased with the increase of styrene contents. The inclusion of styrenic polymers increased the viscosity of the neat EAB. The viscosity of ESBAs increased with the increase of average molecular weights of the styrenic polymers. The addition of styrenic polymers increased the glass transition temperature (Tg) and storage modulus (E′) of the neat EAB. Meanwhile, the inclusion of styrenic polymers weakened the damping properties of the neat EAB. The styrene-butadiene structures had little effect on the Tg and damping properties of ESBAs. The E′ of ESBAs decreased with the increase of styrene contents. The presence of SBS enhanced the thermal stability of the neat EAB. Tensile results showed that the addition of SBS increased the tensile strength of the neat EAB.

Similar content being viewed by others

References

Hunter RN, Self A, Read J (2015) The Shell Bitumen Handbook, 6th edn. ICE Publishing, London

Liu Y, Zhang J, Jiang Y, Li C, Xi Z, Cai J, Xie H (2018) Investigation of secondary phase separation and mechanical properties of epoxy SBS-modified asphalts. Constr Build Mater 165:163–172. https://doi.org/10.1016/j.conbuildmat.2018.01.032

Lesueur D (2009) The colloidal structure of bitumen: consequences on the rheology and on the mechanisms of bitumen modification. Adv Coll Interface Sci 145(1–2):42–82. https://doi.org/10.1016/j.cis.2008.08.011

Yildirim Y (2007) Polymer modified asphalt binders. Constr Build Mater 21(1):66–72. https://doi.org/10.1016/j.conbuildmat.2005.07.007

Drobny JG (2014) Handbook of thermoplastic elastomers: Styrenic Block Copolymers, 2nd edn. Elsevier, Oxford

Masson JF, Bundalo-Perc S, Delgado A (2005) Glass transitions and mixed phases in block SBS. J Polym Sci Part B: Polym Phys 43(3):276–279. https://doi.org/10.1002/polb.20319

Bening RC, Korcz WH, Handlin DL (2003) Styrenic Block Copolymer Elastomers. In: Modern Styrenic Polymers: Polystyrenes and Styrenic Copolymers. Wiley, New York, pp 463–500. https://doi.org/10.1002/0470867213.ch21

Rodrigures C, Hannumanthgari R (2015) Polymer modified bitumens and other modified binders. In: Hunter RN, Self A, Read J (eds) The Shell Bitumen Handbook, 6th edn. ICE Publishing, London, pp 149–216

Jin H, Zhang Y, Wang C, Sun Y, Yuan Z, Pan Y, Xie H, Cheng R (2014) Thermal, mechanical, and morphological properties of soybean oil-based polyurethane/epoxy resin interpenetrating polymer networks (IPNs). J Therm Anal Calorim 117(2):773–781. https://doi.org/10.1007/s10973-014-3849-5

Zhang J, Wang Y, Wang X, Ding G, Pan Y, Xie H, Chen Q, Cheng R (2014) Effects of amino- functionalized carbon nanotubes on the properties of amine- terminated butadiene- acrylonitrile rubber- toughened epoxy resins. J Appl Polym Sci 131(13):40472. https://doi.org/10.1002/App.40472

Xu K, Chen R, Wang C, Sun Y, Zhang J, Liu Y, Xie H, Cheng R (2016) Organomontmorillonite-modified soybean oil-based polyurethane/epoxy resin interpenetrating polymer networks (IPNs). J Therm Anal Calorim 126(3):1253–1260. https://doi.org/10.1007/s10973-016-5795-x

Wang YT, Wang CS, Yin HY, Wang LL, Xie HF, Cheng RS (2012) Carboxyl-terminated butadiene-acrylonitrile-toughened epoxy/carboxyl-modified carbon nanotube nanocomposites: thermal and mechanical properties. Express Polym Lett 6(9):719–728. https://doi.org/10.3144/expresspolymlett.2012.77

Lu Q, Bors J (2015) Alternate uses of epoxy asphalt on bridge decks and roadways. Constr Build Mater 78:18–25. https://doi.org/10.1016/j.conbuildmat.2014.12.125

Maggenti R, Shatnawi S (2017) Initial and replacement riding surface for the orthotropic San Mateo/Hayward Bridge. Bridge Structures 13(2–3):81–92. https://doi.org/10.3233/BRS-170116

Yin H, Zhang Y, Sun Y, Xu W, Yu D, Xie H, Cheng R (2015) Performance of hot mix epoxy asphalt binder and its concrete. Mater Struct 48(11):3825–3835. https://doi.org/10.1617/s11527-014-0442-0

Sun Y, Zhang Y, Xu K, Xu W, Yu D, Zhu L, Xie H, Cheng R (2015) Thermal, mechanical properties, and low-temperature performance of fibrous nanoclay-reinforced epoxy asphalt composites and their concretes. J Appl Polym Sci 132(12):41694. https://doi.org/10.1002/app.41694

Luo S, Qian Z, Yang X, Lu Q (2017) Fatigue behavior of epoxy asphalt concrete and its moisture susceptibility from flexural stiffness and phase angle. Constr Build Mater 145:506–517. https://doi.org/10.1016/j.conbuildmat.2017.04.049

Yin H, Jin H, Wang C, Sun Y, Yuan Z, Xie H, Wang Z, Cheng R (2014) Thermal, damping, and mechanical properties of thermosetting epoxy-modified asphalts. J Therm Anal Calorim 115(2):1073–1080. https://doi.org/10.1007/s10973-013-3449-9

Song M, Liang R, Deng J, Kang Y (2017) Sealed accelerants facilitate epoxy asphalt concretes opening to traffic quickly. Constr Build Mater 147:1–8. https://doi.org/10.1016/j.conbuildmat.2017.04.148

Liu Y, Xi Z, Cai J, Xie H (2017) Laboratory investigation of the properties of epoxy asphalt rubber (EAR). Mater Struct 50(5):219. https://doi.org/10.1617/s11527-017-1089-4

Kang Y, Chen Z, Jiao Z, Huang W (2010) Rubber-like thermosetting epoxy asphalt composites exhibiting atypical yielding behaviors. J Appl Polym Sci 116(3):1678–1685. https://doi.org/10.1002/app.31563

Larsen DO, Alessandrini JL, Bosch A, Cortizo MS (2009) Micro-structural and rheological characteristics of SBS-asphalt blends during their manufacturing. Constr Build Mater 23(8):2769–2774. https://doi.org/10.1016/j.conbuildmat.2009.03.008

ASTM Standard D638 (2003) Standard test method for tensile properties of plastics. ASTM International, West Conshohocken

Elseifi MA, Salari S, Mohammad LN, Hassan M, Daly WH, Dessouky S (2012) New approach to recycling asphalt shingles in hot-mix asphalt. J Mater Civ Eng 24(11):1403–1411. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000520

Bearsley S, Forbes A, Haverkamp R (2004) Direct observation of the asphaltene structure in paving-grade bitumen using confocal laser-scanning microscopy. J Microsc 215:149–155. https://doi.org/10.1111/j.0022-2720.2004.01373.x

Lu X, Langton M, Olofsson P, Redelius P (2005) Wax morphology in bitumen. J Mater Sci 40(8):1893–1900. https://doi.org/10.1007/s10853-005-1208-4

Handle F, Füssl J, Neudl S, Grossegger D, Eberhardsteiner L, Hofko B, Hospodka M, Blab R, Grothe H (2016) The bitumen microstructure: a fluorescent approach. Mater Struct 49(1):167–180. https://doi.org/10.1617/s11527-014-0484-3

Nahar SN, Schmets AJM, Scarpas A, Schitter G (2013) Temperature and thermal history dependence of the microstructure in bituminous materials. Eur Polym J 49(8):1964–1974. https://doi.org/10.1016/j.eurpolymj.2013.03.027

Soenen H, Besamusca J, Fischer HR, Poulikakos LD, Planche J-P, Das PK, Kringos N, Grenfell JRA, Lu X, Chailleux E (2014) Laboratory investigation of bitumen based on round robin DSC and AFM tests. Mater Struct 47(7):1205–1220. https://doi.org/10.1617/s11527-013-0123-4

Liang M, Liang P, Fan W, Qian C, Xin X, Shi J, Nan G (2015) Thermo-rheological behavior and compatibility of modified asphalt with various styrene–butadiene structures in SBS copolymers. Mater Des 88:177–185. https://doi.org/10.1016/j.matdes.2015.09.002

Zhu J, Lu X, Kringos N (2016) Experimental investigation on storage stability and phase separation behaviour of polymer-modified bitumen. Int J Pavement Eng. https://doi.org/10.1080/10298436.2016.1211870

Masson JF, Collins P, Robertson G, Woods JR, Margeson J (2003) Thermodynamics, phase diagrams, and stability of bitumen–polymer blends. Energy Fuels 17(3):714–724. https://doi.org/10.1021/ef0202687

Polacco G, Stastna J, Biondi D, Zanzotto L (2006) Relation between polymer architecture and nonlinear viscoelastic behavior of modified asphalts. Curr Opin Colloid Interface Sci 11(4):230–245. https://doi.org/10.1016/j.cocis.2006.09.001

Kang Y, Song M, Pu L, Liu T (2015) Rheological behaviors of epoxy asphalt binder in comparison of base asphalt binder and SBS modified asphalt binder. Constr Build Mater 76:343–350. https://doi.org/10.1016/j.conbuildmat.2014.12.020

Jansen BJP, Meijer HEH, Lemstra PJ (1999) Processing of (in)tractable polymers using reactive solvents: part 5: morphology control during phase separation. Polymer 40(11):2917–2927. https://doi.org/10.1016/S0032-3861(98)00454-6

Mathew VS, Sinturel C, George SC, Thomas S (2010) Epoxy resin/liquid natural rubber system: secondary phase separation and its impact on mechanical properties. J Mater Sci 45(7):1769–1781. https://doi.org/10.1007/s10853-009-4154-8

Liu Y, Zhang J, Chen R, Cai J, Xi Z, Xie H (2017) Ethylene vinyl acetate copolymer modified epoxy asphalt binders: phase separation evolution and mechanical properties. Constr Build Mater 137:55–65. https://doi.org/10.1016/j.conbuildmat.2017.01.081

Yamanaka K, Inoue T (1990) Phase separation mechanism of rubber-modified epoxy. J Mater Sci 25(1):241–245. https://doi.org/10.1007/bf00544214

Wen G, Zhang Y, Zhang Y, Sun K, Fan Y (2002) Rheological characterization of storage-stable SBS-modified asphalts. Polym Test 21:295–302. https://doi.org/10.1016/S0142-9418(01)00086-1

Polacco G, Filippi S (2014) Vulcanization accelerators as alternative to elemental sulfur to produce storage stable SBS modified asphalts. Constr Build Mater 58:94–100. https://doi.org/10.1016/j.conbuildmat.2014.02.018

Hoppe CE, Galante MJ, Oyanguren PA, Williams RJJ, Girard-Reydet E, Pascault JP (2002) Transparent multiphasic polystyrene/epoxy blends. Polym Eng Sci 42(12):2361–2368. https://doi.org/10.1002/pen.11122

Asphalt Institute (2003) Performance graded asphalt binder specification and testing superpave. Series No. 1 (SP-1). Asphalt Institute, Lexington, KY

Varley RJ (2004) Toughening of epoxy resin systems using low-viscosity additives. Polym Int 53(1):78–84. https://doi.org/10.1002/pi.1321

Wang CS, Wang YT, Liu WJ, Yin HY, Yuan ZR, Wang QJ, Xie HF, Cheng RS (2012) Natural fibrous nanoclay reinforced soy polyol-based polyurethane. Mater Lett 78:85–87. https://doi.org/10.1016/j.matlet.2012.03.067

Wang C, Wu Q, Liu F, An J, Lu R, Xie H, Cheng R (2014) Synthesis and characterization of soy polyol-based polyurethane nanocomposites reinforced with silylated palygorskite. Appl Clay Sci 101:246–252. https://doi.org/10.1016/j.clay.2014.08.009

Xie H, Liu B, Yang H, Wang Z, Shen J, Cheng R (2006) Thermal characterization of carbon-nanofiber-reinforced tetraglycidyl-4,4’-diaminodiphenylmethane/4,4’-diaminodiphenylsulfone epoxy composites. J Appl Polym Sci 100(1):295–298. https://doi.org/10.1002/App.23106

Airey GD (2003) Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 82(14):1709–1719. https://doi.org/10.1016/S0016-2361(03)00146-7

Ho RM, Adedeji A, Giles DW, Hajduk DA, Macosko CW, Bates FS (1997) Microstructure of triblock copolymers in asphalt oligomers. Journal of Polymer Science Part B: Polymer Physics 35 (17):2857–2877. https://doi.org/10.1002/(sici)1099-0488(199712)35:17<2857::aid-polb10>3.0.co;2-6

Rao MD (2003) Recent applications of viscoelastic damping for noise control in automobiles and commercial airplanes. J Sound Vib 262(3):457–474. https://doi.org/10.1016/S0022-460X(03)00106-8

Sun Y, Xu K, Zhang Y, Zhang J, Chen R, Yuan Z, Xie H, Cheng R (2016) Organic montmorillonite reinforced epoxy mortar binders. Constr Build Mater 107:378–384. https://doi.org/10.1016/j.conbuildmat.2016.01.012

Wu J-H, Li C-H, Wu Y-T, Leu M-T, Tsai Y (2010) Thermal resistance and dynamic damping properties of poly (styrene–butadiene–styrene)/thermoplastic polyurethane composites elastomer material. Comp Sci Technol 70(8):1258–1264. https://doi.org/10.1016/j.compscitech.2010.03.014

Zhang F, Hu C (2015) The research for thermal behaviour, creep properties and morphology of SBS-modified asphalt. J Therm Anal Calorim 121(2):651–661. https://doi.org/10.1007/s10973-015-4595-z

Zhang Y, Sun Y, Xu K, Yuan Z, Zhang J, Chen R, Xie H, Cheng R (2015) Brucite modified epoxy mortar binders: flame retardancy, thermal and mechanical characterization. Constr Build Mater 93:1089–1096. https://doi.org/10.1016/j.conbuildmat.2015.05.037

Zhao H, Cao Y, Sit SP, Lineberry Q, Pan W (2011) Thermal characteristics of bitumen pyrolysis. J Therm Anal Calorim 107(2):541–547. https://doi.org/10.1007/s10973-011-1590-x

Sengoz B, Isikyakar G (2008) Evaluation of the properties and microstructure of SBS and EVA polymer modified bitumen. Constr Build Mater 22(9):1897–1905. https://doi.org/10.1016/j.conbuildmat.2007.07.013

Nakanishi H, Takei S, Kasugai N (2005) Strength generation of epoxy asphalt mixture. In: 3rd China-Japan workshop on pavement technologies, Nanjing, China

Singh P, Ghosh AK (2014) Torsional, tensile and structural properties of acrylonitrile–butadiene–styrene clay nanocomposites. Mater Des 55:137–145. https://doi.org/10.1016/j.matdes.2013.09.036

Funding

This study was funded by Priority Academic Program Development of Jiangsu Higher Education Institutions and the Program for Changjiang Scholars and Innovative Research Team in University (PCSIRT).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jiang, Y., Liu, Y., Gong, J. et al. Microstructures, thermal and mechanical properties of epoxy asphalt binder modified by SBS containing various styrene-butadiene structures. Mater Struct 51, 86 (2018). https://doi.org/10.1617/s11527-018-1217-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-018-1217-9