Abstract

The brazing ability and the mechanical shear strength of the joint of the dissimilar pair of TiC/Cu–20Ni composite to Cu–20Ni alloy were investigated. The filler material was a film of the amorphous base-nickel alloy BNi-3 containing B and Si as melting point depressants that improve the fluidity of the liquid formed. The composite with 60 vol% reinforcement of TiC particles was manufactured by liquid infiltration. As a result of brazing at 1060 °C, secondary TiC fines formed due to a solution–precipitation phenomenon of the surface of the reinforcement in contact with the joint derived from the high-nickel content in the molten filler material. The greater the bonding time, the greater the resistance of the TiC/Cu–20Ni||BNi-3||Cu–20Ni assembly, achieving a maximum shear strength of 101.8 MPa. The secondary particles at the interface and the greater diffusion of filler material species over time allowed the increase in shear strength.

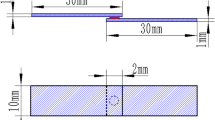

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

S. Pramanik, J. Cherusseri, N. Baban, L. Sowntharya, K. Kar, Metal matrix composites: theory, techniques, and applications. In: Composite Materials (Springer, Berlin, 2017), pp. 369–411

N. Chawla, K. Chawla, Metal Matrix Composites (Springer, New York, 2006)

C.A. Leon, G. Rodriguez-Ortiz, E.A. Aguilar-Reyes, Mat Sci Eng A (2009). https://doi.org/10.1016/j.msea.2009.07.002

C.A. León-Patiño, E.A. Aguilar-Reyes, M. Braulio-Sánchez, G. Rodríguez-Ortiz, E. Bedolla Becerril, Mater. Des. (2014). https://doi.org/10.1016/j.matdes.2013.09.011

M.A. Téllez Villaseñor, C.A. León Patiño, R.G. Martínez, E.A. Aguilar Reyes, MRS Adv. (2019). https://doi.org/10.1557/adv.2019.492

P. Fernández, M.V. Martínez, M. Valencia, J. Cruz, DYNA (Colomb.) 149, 131–140 (2006)

Y. Dong, R. Zhang, X. He, Z. Ye, X. Qu, Mater. Des. (2012). https://doi.org/10.1016/j.matdes.2013.06.074

P. Roberts, Industrial Brazing Practice, 2nd edn. (CRC Press, Boca Raton, 2013), pp.15–58

M. Salvo, V. Casalegno, S. Rizzo, F. Smeacetto, M. Ferraris, M. Merola, J. Nucl. Mater. (2008). https://doi.org/10.1016/j.jnucmat.2007.07.010

L.X. Zhang, J.C. Feng, P. He, Mater. Sci. (2006). https://doi.org/10.1016/j.msea.2005.11.044

S.S. Sayyedain, H.R. Salimijazi, M.R. Toroghinejad, F. Karimzadeh, Mater. Des. (2014). https://doi.org/10.1016/j.matdes.2013.06.074

N. Bouzegzi, D. Miroud, F. Ahnia, G. Alcala, F.J. Perez, K. Khenfer, M. Tata, S. Mato, J. Alloy Compds. (2018). https://doi.org/10.1016/j.jallcom.2018.05.141

W. Peng, G. Zeng, L. Jinzhu, C. Dongfeng, N. Jitai, Compos. Interfaces (2019). https://doi.org/10.1080/09276440.2019.1580531

D. Cabrera De La Cruz, C.A. León Patiño, R. Galván Martínez, Materialia (2018). https://doi.org/10.1590/S1517-707620180002.0385

J. Asadi, S. Sajjadi, H. Omidvar, J. Manuf. Process. (2020). https://doi.org/10.1016/j.jmapro.2020.09.016

X. Guojing, L. Xuesong, J. Han, X. Ziyang, Y. Jiuchun, J. Manuf. Process. (2020). https://doi.org/10.1016/j.jmapro.2020.02.046

D. Duo, Z. Dongdong, Z. Huixia, W. Gang, X. Haitao, L. Feng, H. Qin, N. Chengyuan, Vacuum (2018). https://doi.org/10.1016/j.vacuum.2018.08.012

C.A. León-Patiño, M. Braulio Sánchez, E.A. Aguilar Reyes, E. Bedolla Becerril, J. Alloy Compds. (2019). https://doi.org/10.1016/j.jallcom.2019.04.132

Q. Qi, Y. Liu, H. Zhang, J. Zhao, L. Gai, Z. Huang, Adv. Eng. Mater. (2016). https://doi.org/10.1002/adem.201600190

C.A. León Patiño, A. Miranda López, E.A. Aguilar Reyes, G. Rodríguez Ortiz, Wear (2020). https://doi.org/10.1016/j.wear.2021.203667

M. Bober, S. Jacek, L. Hong, Materials (2021). https://doi.org/10.3390/ma14216617

S.Y. Chang, Y.T. Hung, T.H. Chuang, J. Mater. Eng. Perform. (2003). https://doi.org/10.1361/105994903770343240

I.M. Subas, J. Manuf. Process. (2020). https://doi.org/10.1016/j.jmapro.2020.08.058

Acknowledgments

This work was supported by the National Council of Science and Technology (CONACYT-Mexico) through the Grant 222255 and CIC-UMSNH Mexico. CONACYT is recognized for the Scholarship granted to Juan José Laguna Gasca.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Carlos A. León-Patiño was an editor of this journal during the review and decision stage. For the MRS Advances policy on review and publication of manuscripts authored by editors, please refer to mrs.org/editor-manuscripts.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

León-Patiño, C.A., Laguna-Gasca, J.J., Aguilar-Reyes, E.A. et al. Mechanical and microstructural characterization of brazing joints of the TiC/Cu–20Ni composite to Cu–20Ni. MRS Advances 8, 39–45 (2023). https://doi.org/10.1557/s43580-022-00483-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-022-00483-0